<< New Q&A More Q&A, part 7

>> Part 6 >> Part

5 >> Part 4 >> Part 3 >> Part 2 >>

Part 1 >> Gunwriters

guns.connect.fi Link page

Custom Search

Part 8, update 05.11.2000

G.O.W. Kickback:

Questions and Answers

Part 8. Answered by: P. T. Kekkonen

Tumbling .22 bullets

Dear Pete, because I'm interested in the techniques, I've build a sound suppressor for my

.22 LR rifle. The thing is, using Winchester subsonic ammo, it is silencing very very

well. However, the bullets coming out are "tumbling". So you can imagine that

the accuracy is below any level. At 50 m, I cannot even hit the chart. (Without silencer

within two cm @ 50 m).

Technical data: Material RVS/Alu. Overall length 215 mm. Internal diam. of outer tube is

28 mm. Internal diam. of inner tube is 16 mm. Outer diam. of inner tube 17 mm. Inner tube

containing 5 conical baffles having a hole of 6.0 mm Inner tube containing also 3

"straight" baffles with a hole of 6.2 mm. Endcap hole 6.5 mm. See also attached

.bmp sketch. As far as I can see, I don't think the bullet is hitting any of the baffles.

Please can you help me on this issue?

Looking out for your answer. Kind regards, Jos (from Netherlands).

Our

"telegraph operator" was unable to pick open your sketch. (This is not so

uncommon situation: I'm calling E-mail as "A Picture Scrambler"). I am unable to

see any pictures by the screen of my computer, programmed to be "typewriter

only". I must receive all kinds of illustration as paper prints. And the most sure

way to send the illustrative material to me/us is ancient slow mail/postal letter in the

envelope. Stamped and addressed: GOW. P.O. BOX 525. FIN-80161 JOENSUU. FINLAND.

I am, however, able to imagine your suppressor design, which is functional, although it is

somewhat overly complicated for .22 LR rifle. Source of tumbling problems is too small

bullet passages, holes with 6.0 to 6.5 mm diameter. Absolute minimum passage diameter

through a rearmost baffle is 7 to 7.5 mm and the diameter of endcap bullet passage of a

suppressor with overall lengtht 215 mm must be at least 7.5 mm but preferably 8.0 mm.

Suppression effect of your device shall become somewhat reduced after enlargement of the

passages: "There are no free lunches", but you can shoot within 20 mm @ 50

meters also with a mounted suppressor.

(Have you tried Mexican PMC "Moderator" .22 LR cartridges

with 38 grs HP bullet? It is the very first TRULY subsonic load in .22 LR class, without

excessive muzzle velocity or too long/ unstable bullet. We are collecting user's comments

about performance of PMCM cartridges for further developement of subsonic .22 rimfire

load, designed to give reliable functioning in any & all autoloading firearms actions,

with intermediate-sized cases and bullet weight ca. 50 grains. This cartridge is designed

in 1992: Finnish conception but manufacturer of it is still "wanted". PMC is the

very most promising candidate).

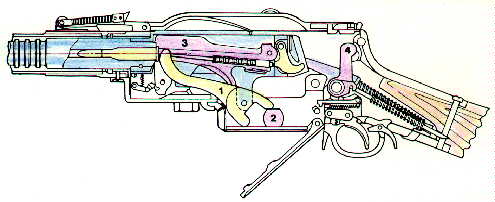

Experience of mine and other designers (since Hiram Percy Maxim

(image of a Maxim silencer beside) in early 1900s and,

presumably, Russian Colonel Humbert in the late 19th century) has taught those

minimum passage dimensions. A suppressor may be mounted with zero errors of co-axiality

and concentricity. Rifling of the bore may be perfect. "Crowning" of a rifle

muzzle may be faultless. Still, if you shoot bullets with diameter 5.7 mm (or slightly

less) through passages with dia. 6 to 6.5 mm, the dispersion of hits may be as broad as

the pattern of cylinder-bored shotgun loaded with 5.5 mm "swan drop" shot

pellets. "Why?"

Because a .22 LR bullet NEVER starts straight from the cartridge case. There is a

clearance between a cartridge and chamber, and the bullet's base is NEVER perfectly

symmetrical, when pushed through the crimp of case mouth. Every bullet emerges the muzzle

with some yaw, known as "nutation" in Latin. When the side of nutating bullet

grazes the edge of a passage hole, it's course shall be diverted away from the original

trajectory at random direction. Divergence, mere one Minute Of Angle shall divert the the

hit ca. 15 millimeters from the aim point @ 50 meters distance. The bullet, which has

usually grazed many (all?) baffles and endcap passage hole, shall also gain a more harmful

yaw, known as "precession" in Latin (and nomenclature of ballisticians).

Nutation is a rapid movement with a rate equal with a rotational rate gained from the bore

rifling twist. Precession is considerably slower yaw with more prominent amplitude. It is

able to cause a spiral "corkscrew trajectory", often seen when shooting tracer

bullets from a rifle with a faulty muzzle (and from a Madsen light machine gun, despite of

a perfect muzzle. Action of Madsen (see drawing beside)

shall bend the bullets of it's cartridges slightly askew before discharge. Therefore it

was a very LETHAL "mowing machine" and it was produced during a more long time

than any other light machine gun: Since 1904 until late 1950s or early 60s, despite of

it's high price).

Bullet's precession at random direction and rate shall deteriorate the accuracy so badly

that it is impossible to hit a chart @ 50 meters or broad side of a barn @ 100 meters.

(Precession produced by Madsen action was predicted: It's direction and rate were the

same, shot-after-shot. Accuracy at known range was satisfactory, despite of the

"corkscrew trajectory").

Drill the bullet passages of your suppressor baffles and endcap to diameter 7.5 mm: Your

anxiety shall be over! In your present design the bullets does not HIT the baffles, but

just a slight GRAZE is needed to deteriorate the shooting accuracy. A clearance of bullet

passages is essential! Each & every suppressor designer has presumably learnt this

fact by the hard way: Me too, in early 1970s, when knowledge re suppressor designs was

less easily available than it is today.

1710 MM; PT

A couple of questions

First: The last posts I saw stated that you would not be updating after July of

2000? Is this correct and can we in the US still contribute to your pages? I have learned

much about the KP31 in addition to the Q & A section and would like to help if its

still possible.

Second: I would like to ask a few questions - I have recently acquired a

deactivated Lahti L/39 that I would like to repair and shoot. I

know there are others out there with the same problem of ammunition availability that we

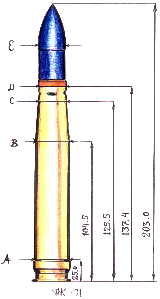

have here in the US so posting answers would be the best. The 20X138B cartridge is quite

difficult to find in this country while the 20X103 US is very common. The major problem

from my point of view is that while the 20X138B has chamber pressures in the 3000 atm

range the 20X103 is in the 4200 atm range. I feel that the barrels available will

withstand the pressures but I am worried about the locking mechanisms of a 50+ year old

rifle that was designed for significantly lower pressure.

I know that it is possible to load the 20X103 to a lower pressure but I am aware that

simply reducing the powder charge can easily increase the pressure to explosive

proportions. I do not have the knowledge of years of reloading or of the principles

involved. The 20X103 normally uses 590gr of winchester WC872 and a projectile weight of

1500gr or 620gr WC872 and a projectile weight of 2000gr. Both of those loadings, according

to the US military cartridge specification book, have chamber pressures in the 4100-4250

atm range. After all that I suppose my question is this : is there a powder and loading

that will allow me to load the 20X103 with projectile weights of 1000-2400gr to a pressure

that is more nearly that of the 20X138B? Should I just do as some others have done and

machine 20X138B cases from bar stock and shoot more infrequently?

Thanks for your pages and help: Frank

First.

We tried (in vane) to collect our nominal annual fee USD 10.00 by the international money

transfer system, until 1st July 2000. Then we hired a P.O. Box for payments in cash, but

in the late October 2000 we have no more than three Privileged Visitors (living abroad) on

our register. It is very frustrating to publish the website in English for three Patron

Visitors and several thousands of "pirate visitors" (including armies and

firearms manufactures!). Updating of GOW/Universal website (in English) has been

continuing until these days, but I have chosen the questions for Q & A section more

carefully and we are suppressed production of articles in English.

There are less than a handful of gunwriters contributing to GOW sites. Another site is

published in Finnish only, and because Finnish visitors are keeping up our activity, they

are also privileged to get information by GOW/Finnish site. As you can see, we are

nowadays publishing not only Q & A section "Tokko tietoa

on?" or "Kalkkivaari" causeries, but also

technical/ historical articles in Finnish; more and more of them. If we shall receive more

USDs than Finnish Marks into our P.O. Box, we are able (and willing) to pay more attention

to evolution of GOW/Universal site, but if the GOW/Finnish site is more profitable, the

effort of updating and evolution shall become concentrated to it, and our Universal site

shall fade away. We are not greedy for money: We are just willing to SURVIVE.!

Second: I think, the most advisable way is to turn 20

mm Solo Long cases from a brass or steel bar stock and load them with the

reduced charges of quickly burning powder (able to ignite and burn under the low chamber

pressures). L-39 is unable to stand full 3100 pressures, if deactivated and

"regenerated" to become shootable again! Please, do not try to load reduced

charges with the usual "cannon powders" like WC 872, even into the

"Everlasting cases" with considerably reduced powder space.

You must forget automatic functioning of the regenerated action and even the magazine

feed, when shooting cartridges loaded into the Everlasting cases of rather brittle brass

or free-cut steel, containing sulphur and lead to make the chips short. The brass contain

ca. 3 % lead and just 57 % copper to become easy to turn with automatic machines

(originally invented by Christopher M. Spencer, known as an "automatic

screw-machine with a cam guidance"). Recommended pressure level is about similar tho

that of a 12 ga/ 3" Magnum shotshell, id est: Preferably less than 1000 atmospheres.

All the rifle powders are unsuitable for reduced charges; even the quickly-burning Finnish

VihtaVuori N110. One defiant Finn didn't believe on the friendly warnings, when he was

loading cartridges for his regenerated L-39. After the first shot he was lying on his back

(SIC!) with a broken collar-bone and three broken ribs. Some fragments of his rifle are

lost forever. The Broemel QuickLOAD program is able to compute

handloads even for the 20 x 138 mm Solothurn Long cartridges. It gave a safe combination

of components as follows:

Brass case for a German Anti-Aircraft cannon (B.S.W.). Projectile weight: 120 grams, usual

bore-riding projectile with a copper or sintered iron driving/ rotation band. Charge: 8.0

grams of VihtaVuori N310 powder (SIC!), preferably in the cotton-gauze bag rammed into

head-end of the case. Calculated muzzle velocity is subsonic, slightly less than 300

meters per second with a chamber pressure 1500 atm (=less than half from an allowed

maximum).

For the cases with reduced volume (cylindrical powder space, diameter 20 mm) the charge

must be further reduced, and the chamber pressure 1500 atmospheres may be too high for

regenerated L-39 action.

"Of a truth I say unto you": Deactivation of firearms is a criminal offence; a

felony; a more serious crime than a murder, a genoside, or the WW II Holocaust!

Deactivation itself is a routine of gunsmithing trade, but the politicians and those lousy

legislators, enacting laws or acts insisting on deactivations, are deserved a legitimate

punishment by the most painful methods developed by Gestapo or KGB - or Satan

himself/herself.

1910 MM; PT

Willi Daugs: The unknown industrialist

I came across your articles on the Internet, while searching for the name WILLY DAUGS (for general biographical purposes). Do you happen to

know the places and dates of birth and death of Mr. Daugs.

Hoping to hear from you, I remain, yours faithfully, Archibald

Sorry, I

don't have information about "Circulum Vitae" of Mr. Daugs more than is

published in Finland and England. Finnish printed sources of information are ignorant even

about the year when Wilhelm/ Willi (N.B: Not Willy) Daugs arrived in

Finland. He became a main stockholder of Tikkakoski O/Y during the first year of

Great Depression, in 1930. Place and date of his birth is unknown to me. The very last

mention about Willi Daugs I found from "The Illustrated Encyclopedia of

Firearms" by Ian V. Hogg, published in 1978 by Hamlyn: "He (W. Daugs) is

believed to have gone to South America, but has not been active in the small arms design

field since the early 1960s".

1710 MM; PT

Hi Mr Pete

Hi Mr Pete

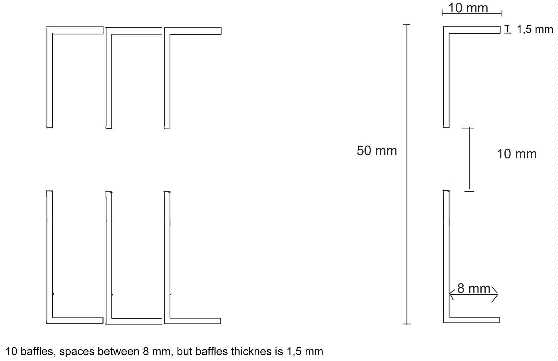

I received your last message. Thank you for all information. I have one more question. Why

the baffles must have thickness 8 mm? I would like to make and use another baffles (shape

"["). I enclose drawing of my design baffles to my message. (see baffle image beside). I think that

baffles of my design take less place in suppressor jacket (more expansion gas place). I

used this shape of baffles in my .22 LR suppressor. Does the suppressing effect depend on

the baffle thicknes and diameter of bullet passage?

P.S. It is almost impossible obtain the catalogue you ask me for. I will try to find

something interesting about it but it may take a lot of time. All I find I'll send on your

address.

Emil

Thickness of baffles about equal with bullet diameter is not essential. 8 mm was

recommended because of simplicity. The rearmost aluminium baffle must be thick, but those

other "septums" may be shaped just like you are doing. Enlargement of bullet

passage(s) shall curtail the sound suppression effect, but some clearance between

passage(s) and bullet is essential! Bullets emerging from muzzle have ALWAYS some

"yaw" movement, known as "nutation" and if the bullet grazes edge of

any passage, you should say: "Goodbye, dear Shooting Accuracy!"

I have also seen MANY suppressors literally ruined by improper mounting or making the

bullet passages too small. Especially the excessively long projectiles (marginally stable

bullets) may turn aside and emerge crosswise from the suppressor after a slight graze to

the rearmost baffle. Sometimes the unstable bullet has perforated side of a suppressor

jacket. So: Better safe than sorry! A couple of decibels extra noise of shooting is never

too high price of the safe and accurate shooting.

2710 MM; PT

Reloading 7.62 mm Nagant cartridges

Had a couple of questions I hoped you could help with. Do you have any advice on loading

the 7.62 mm Nagant cartridge?

Is there any way to modify the Berdan cases to use Boxer primers? I was hoping you clever

Finns have come up with a field method of reloading the cartridges. I can locate Berdan

primers, if necessary, but the few reloading components in this country are made more for

using the Fiocchi cases. I have several hundred rounds of the Russian target loads I don't

want to waste.

Thanks. Dave

No reloading

components for 7.62 mm Nagant (Russian revolver) cartridges?! Just lack of imagination!

You may use many bullets, from N:o 0 buckshot to Lyman N:o 311 316 cast bullet (sized to

.309") and any & all jacketed bullets with round or flat nose/ hollow point,

diameter .308" or .309" and weight 70 to 110 grains. If you must duplicate the

factory load, you may obtain soft-point RN bullets designed for .30 M1 Carbine cartridges

(weight 110 grains) and cut away lead tip, visible from the jacket. You have a bullet with

a weight and ballistic coefficient ABOUT similar to the original Nagant FMJ bullet,

flat-pointed one with weight 108 grains.

Your is still a soft-point projectile, but because muzzle velocity of safe 7.62 mm Nagant

load is less than 1000 feet per second, there is no difference. You'll not be obliged to

obey those funny "DumDum Ban" rules of Haque

Convention, and the carbine bullet shall presumanly not expand when shot with

available velocity. If you'll need more penetration, use 110 gr FMJ round-point M1 Carbine

bullets. Most proper propellant for Nagant loads is Czechian pistol powder, imported in

USA by Accurate Arms and distributed as AA No. 2. Unfortunately I have no idea about the

charges of AA No. 2 for 7.62 mm Nagant handloads for the unknown cases.

Feel free to ask from our friend Markus some loading advices, giving to him barrel length

of your Nagant and grain-weight of pure water, filling the empty cartridge case up to it's

mouth. There is caliber 7.65 Russ. Nagant programmed into his Broemel QuickLOAD computer

program, along with information re AA No. 2 powder and many bullets fit for Nagant

cartridges. E-mail address of Markus is markuspnk@hotmail.com.

Nagant cartridges are usually loaded with Alliant/Hercules Bullseye powder with .308 Speer

Plinker semi-jacketed bullets, weight 100 grains, and charges (up to) 3.5 grs of Bullseye.

Nominal muzzle velocity with this mild & safe load is 1000 feet per second; more than

the measured velocity of Fiocchi loads but the Plinker bullet is less heavy than

projectile of Fiocchi's factory loads.

Those Bullseye loads are tried in USA. Alliant's powders are unavailable in Finland and

not many Finns are reloading Nagant cartridges. It is said on a book "Cartridges Of

The World" by Frank C. Barnes that 7.62 mm Nagant cases can be made from .32 - 20

Winchester cases, but I've never tried, whether it is right assertion or "hugaa"

(= in English "wahoo" = bullshit). A .32 - 20 case is too short to

offer sufficient gas-seal, I think so. Base diameter is, however, correct. Original

Russian cases may have primer pockets for intermediate-sized Berdan primers; diameter 5.0

millimeters, height 2.2 mm. (Dia .197", hght .09"). German RWS made in 1973 and

may still produce these primers "Number 5005".

I afraid that it is unreasonable to try modification of Berdan primer pocket for Boxer

primers, although it is easy to drill a central flash hole through the bottom or

"web" of a primer pocket and ream the pocket for Large Pistol sized primers. It

may also be frustrating to line the pockets with thin-walled sleeves for Small Pistol

primers. Why? Because height of Boxer pistol primer - large or small - is 3.10

millimeters/ .122". If the primer pocket is reamed to become deep enough, the web

thickness may be zero millimeters - or negative. A pocket, without bottom at all, shall

offer no support for the primer's anvil.

If you can obtain Berdan primers of correct diameter and height, you may reload your

Russian Nagant cases easily. Depriming of cases is not difficult with hydraulic pressure:

Fill the case with water (= dilute suds) and pressurize the liquid with a plunger, fitting

into the case mouth. (This plunger may be of metal, plastic or wax-impregnated hardwood).

"Depriming anvil" must have a concentric channel, large enough to let the primer

to fall through it in any position, and a recess for the case rim. Place a water-filled

case standing on the anvil and a plunger into the case mouth. One gentle tap with a light

plastic hammer or mallet on the plunger end is usually enough to remove the shallow

primer. The case and primer pocket shall become washed and flash holes rinsed open with a

hydraulic liquid without more effort.

The "hydraulic liquid" (water with some soap or detergent added) is somewhat

unpleasant in use. You'll find very soon that a bathroom is an ideal workshop for

"wet depriming" and no much more clothes are needed but swimming suit and rubber

or plastic cloves, plus goggles for eye protection. Deprime the cases before resizing.

Hydraulic pressure inside the rather thin-walled shell may cause some swelling of it. If

you please, you may drill one of the priming flash holes as large as possible to drill

without damage of fixed primer pocket anvil and edge of the pocket. After the next

reloading and shooting you may push the primer out with a pick or "awl". You

must, of course, remove the central depriming pin from your reloading die, because the

drilled flash hole is eccentric.

Berdan primer is "A Curse of Reloading Class". Blessed are the firms, like

Australian Bertram, yielding modern brass cases (empty shells) with Boxer priming

pockets for obsolete or obsolescent firearms. I don't know, whether they are available in

The People's Republic of California or whether 7.62 mm Russian Nagant shells are produced,

but I think, they are.

1510 MM; PT

Notice to visitors of GOW/Universal:

Dave is one of our three "Privileged Visitors"; first one who

has paid our nominal US $ 10.00 annual fee. Another "Patron Visitor"

lives in New Zealand and third one in Norway. Some more wealthy visitors, like United

States Army and one Czechian firearms factory, are milking all the information (even

that published on GOW/Finnish site) free. Presumably they are thinking that publishing of

our website is just a hobby of some "Leisured Class" youngsters and not a

serious work at all.

There were overwhelming difficulties to collect fees or "alms" by a currency

transfer systems. So we hired in 1st July 2000 a P.O. Box for collection of alms in cash

by letters. Finnish Patron Visitors have found this alternative collection method

convenient, but just those three Privileged Visitors living abroad have paid their Debt of

Honor. Nowadays we are considering to limit the issue of GOW/Universal just to our Patron

Visitors, transmitting it by E-mail as "private only" messages and no more by

"broadcasting" it on the Web.

This system is already adopted: Many visitors asking questions have received answers with

"private/personal only" annotation from me to our telegraph operator. You have

presumably noted that text material on GOW/Universal (in English) is diminishing, while

text and illustration material on GOW/Finnish site has increased steadily. Finnish

visitors are keeping up our activities. Therefore the Finns are privileged to get some new

information, including illustrated articles.

They are written in Finnish, of course, and in so highly specific "gun-nut's

slang" that the Anglo-Finnish translating programs are able to find no more than

every third word; just those terms owing many meanings. Those articles are completed

reprints of stories published in periodicals. Nomenclature and glossary of them was chosen

so that just "hardcore gun-nuts" could comprehend it, but censors in the

editorial staffs could not grasp it's real meaning. Even the "standard Finnish"

is very difficult to learn and almost impossible to translate correctly by the mechanical

means. And a slight misconception of the most delicate handloading data may produce

disaster.

You may believe that contribution to GOW/Finnish site only shall easily take all our time,

when done with scrupulosity, editing Questions & Answers column (with less active use

of "DELETE" key) and publishing more reprinted or "virgin" articles,

searching relevant illustration, proof-reading & revising texts of other contributors,

et cetera. It is very frustrating bustle to publish GOW/Universal site for just three

Patron Visitors. So I hope that number of them shall become increasing.

Our mail/postal address is:

GOW

P.O. BOX 525.

FIN-80161 JOENSUU

FINLAND

EUROPE

(on the letters from other continents. Please, do not forget your E-mail address from your

letter. It is needed for our record of Patron Visitors).

PS. Visitor L.D. from Norway: Please, send to us your E-mail address, or

address of E-mail you can utilize. Our Privileged Visitors are still privileged,

despite of imminent suppression of GOW/Universal. Contact me by E-mail, address ptkekkonen@hotmail.com or by letter to our

P.O.Box.

1510 MM; PT

VOERE KUFSTEIN

I do not read in Austria's tongue but I can tell you what is engraved on my rifle. I lost

the clip for this particular gun and I am wondering where I can get another one. The gun

is a .22 cal semi-automatic and the clip holds between 8 and 10 shells and is a long

rectangular type clip. Here's what is written on the gun. Left and Right are relative to

the gun being in your hands, up to your eye and aimimg. Engraved on the left side of the

barrel is: VOERE KUFSTEIN/ AUSTRIA CAL .22 L.r. 152337. Engraved on the right side of the

barrel is: LAUFSTAHL 3. Forever greatful if you can help!

Cheers and thanks, Brian

Austrian

tongue is German. Kufstein may be the town or region where your rifle is made. 152337 is a

serial number. Model number may be Voere 2115. LAUFSTAHL 3 means "barrel

steel" (Boehler N:r 3). If there is a plastic magazine support integral with a

trigger guard, and Monte-Carlo buttstock comb, the model is 2115. Clips for it

are still available. There were (still are?) available clips either for 8 or 15 rds of

cartridges. You must now leaf a book "Gun Digest" and look, whether on it is

mentioned address of existing U.S. importer of Austrian (not German) Voere rifles and

order the magazines by some sporting-goods shop or directly from the importer.

My most fresh edition of Gun Digest is published in MCMLXXXVI (1986). It is 41st Annual

Edition. Many addresses mentioned on it are presumably no more valid or up-to-date. In

1986 the importer of Austrian Voere rifles was a firm L. Joseph Rahn.

1610 MM; PT

Suppressor & supu-loads for 7.62 x 39 mm

Thank you for your information about suppressors for .22 LR. I made the suppressor and

subsonic ammo and it works very well.

But now I would like to make suppressor for handloaded 7,62 x 39 (rifle with Kalashnikov

barrel). I would like to go by Kalashnikov Reflex Suppressor

(KRS) design but I'm not able to make cup-shaped baffles. I would use flat baffles the

same way as Humbert's Chamber design (first baffle with a diffractor). My questions are:

1. Could you instruct me how long suppressor should be, its diameter, bullet holes (10,5

mm?) and number of baffles?

Outside

diameter ca. 50 mm, jacket wall thickness ca. one millimeter, inside length ca. 200 mm.

Ten baffles, thickness 8 mm spaces between them also 8 mm. Bullet passage diameter 9 to 11

mm, depends on carefulness of suppressor mounting.

Cross-sectional view of a common 12 baffle Kalashnikov Reflex

Suppressor KRS at right.

2. How to make the subsonic ammo? I'm using Polish Army ammo

(bullet weight is 7,91 g). How much powder should my ammo contain?

You

should NOT use reduced charges of rifle powder, salvaged from full-powered cartridges! If

you can obtain blank cartridges, you may use quickly-burning powder of them. Usual

starting load of blank cartridge powder is 0.25 gram. The charge is gradually increased

until flight of some bullets is "cracky", and then reduced to previous tested

charge. There may be so-called "launching cartridges" (for 7.62 x 39 mm assault

rifle) available in Poland, loaded for launching of rifle grenades.

I don't know characteristics of launching cartridge powder. Do not use it for reduced

charges, unless it is examined and found to be safe propellant for subsonic loads.

Suitable blank cartridge powder is found from cartridges with WOODEN bullets or those with

PLASTIC cases. As far as I know, Polish launching cartridges have "rosette

crimp" case mouth and no bullet at all.

Also I don't know, what kinds of powder are available for handloading in Poland and their

characteristics, but those propellants recommended for loading of 6.35 mm, 7.65 mm, or 9

mm Browning pocket-pistol cartridges or lightest target loads of shotgun (say: 24 to 28

grams of shots in 12 gauge shotshells) are good also for subsonic loads of 7.62 x 39 mm

cartridges. Starting load 0.26 gram is found to be safe, if the powder is applicable

(easy-to-ignite; "flammable" enough) for use in subsonic cartridges.

A propos: Did you know that Finnish ballistician Ole Mélart was a main advisor

when manufacture of Polish shotshells was re-established after Second World War?

Brand-name of shotshells was "Boar" and powder of them was similar to Finnish

VihtaVuori N320, or it was N320 exported from Finland. Mr. Mélart designed Boar

cartridges to be reliable also in cold climate. Contemporary product number of N320 was

N22, until 1st Sept. 1973. This powder is good for reduced 7.62 x 39 mm loads. Charge

weight for subsonic loads is 0.27 - 0.28 gram of N320.

If you can obtain some catalogue or list about powders and other

handloading components available in Poland, I am interested in it. Please, send it or them

to me by mail. Address is: GOW, P.O. BOX 525, FIN-80161, FINLAND. (I cannot read Polish

very much, but just well enough).

3. Will the KRS design (with Humbert's design disc baffles)

be more effective than Russian PBS (device for noiseless shooting) design?

Cross-sectional view of a PBS at right.

I think,

you may build a more efficient suppressor than is Pribor dlya Besshumnoy Stryelbiy.

Rubber "shoot-through" baffles (known as wipes) of PBS shall become ineffective

after shooting less than a hundred shots and they'll deteriorate accuracy of shooting.

Silencing effect of Humbert Design chamber suppressor is better. Rubber wipes of PBS are

actually needed to generate autoloading function for Kalashnikov assault rifles with

subsonic loads. Otherwise is PBS a variant of Humbert's suppressor, with thin baffles and

extra large bullet passages, however.

Table beside: PBS noise level

curve with subsonic ammunition as compared to KRS (in

Finnish MPV for Maanpuolustusvaimennin meaning "Defence Suppressor")

sound levels. PBS noise levels show increase as the wipes fracture during shooting.

Measured with 20 shots through a virgin (unpunched) wipe. Sound meter position was 10

meters to the side of the weapon.

Table beside: PBS noise level

curve with subsonic ammunition as compared to KRS (in

Finnish MPV for Maanpuolustusvaimennin meaning "Defence Suppressor")

sound levels. PBS noise levels show increase as the wipes fracture during shooting.

Measured with 20 shots through a virgin (unpunched) wipe. Sound meter position was 10

meters to the side of the weapon.

4. I like know what kind of suppressor is this one you

mentioned - Finnish SuoMet suppressor with a helical-groove spiral diffuser? Have

you got design (draw) of this one. I'd appreciate if you send me it or give me Website

address where I can find it.

Firm SuoMet

Oy was gone almost two decades ago. It was re-christened as Vaime Oy in

early 1980s. Later it was known as Laxmit Metal Oy. In early 1990s it went

entirely out from business. My good friend Mitsuo Taguchi (citizen of Japan but

living in Finland in my neighborhood) designed and patented an improved design of

suppressor in early 1980s. Vaime Oy adopted his invention, still known as Vaime Design.

Earlier spiral diffuser construction was dispensed with, since it was unpleasant to use

with self-loading firearms, generating a rather noisy "back blast". Selfloader

guns could also spit unburned powder kernels towards the face of shooter and into the

mechanism of firearms. SuoMet suppressor was, however, efficient with manually loaded .22

LR firearms; especially rifles.

I think, it had a primary gas expansion chamber not long enough between the muzzle and

(overly long) spiral diffuser. That diffuser was an aluminium rod drilled through with a

bullet passage, diameter 7.5 mm. On the rod was turned a spiral groove, similar to the

thread of a vise screw. I have never seen the drawings of SuoMet suppressor and it was a

"sealed unit", impossible to disassembly. I owned one specimen, mounted by

SuoMet Oy to my .22 LR "Margo Combat" prototype pistol (Margolin MCM with four

inch barrel length), but I sold the pistol to one enthusiastic collector ca. fifteen years

ago, along with it's suppressor. I think, my prototype was a very first Margo pistol in

the World. (Especially one with a suppressor mounting thread on it's muzzle). Russians

started factory production of it after the collapse of Soviet administration.

I'm waiting for your reply prompt.

Emil, from Poland

and comment:

Due to the somewhat complicated arrangements of my contribution to GOW sites, there are no

prompt replies available. Delay is usually two weeks from the arrival of questions and

transmission of answers. Our Finnish visitors are privileged to get answers, since they

are keeping up GOW by the annual fees. Even the United States Army isn't wealthy enough to

pay our nominal USD 10:00 per annum "alms": Oh, what a Global Misery! (Oh, what

a miserliness..??).

3009 MM; PT

20 mm "mickhaque" case

I was handed down a cartridge case which was found in our garden in Folkestone, England by

my father in 1940. The base has the markings 'BMARO 1940 20mm ZI'. Would you know how I

could track down its source? I assume it was a German aircraft origin.

Many thanks: Martin

Headstamp of the case is actually "BMARC", abbreviation from words "British

Manufacturing And Research Co." (A loader of 20 mm Hispano-Suiza

cartridges in Grantham, England). Letters "ZI" denotes use of nitro-cellulose

propellant (powder), loaded into those cartridges, which must function in very cold

climate, like altitudes of the sky. Therefore it was preferred over Cordite propellant for

cartridges of aircraft weapons. Powder manufacturer has been Imperial Chemical

Industries. "1940" is year of manufacturing and "20 mm" denotes

the calibre. The case was presumably dropped from Supermarine "Spitfire"

or some other British fighter aircraft during a dog-fight.

Word "mickhaque" is somewhat irrelevant, meaning a small long-barreled cannon,

calibre 20 to 30 mm. These infantry cannons with light carriages were used as a sniping

firearms during 16th Century in Scandinavia, including Finland, and North-West Russia. In

Swedish the word was spelt as "mickhake" and in Finnish as "nikhaka".

In French the name of these firearms was "amusette". Many times they were

breech-loaders, already in 16th or 17th Century. Hispano-Suiza aircraft cannons shot burst

or full-auto fire, of course.

2309 MM; PT

Efficiency of subsonic loads

Hello Mr. Kekkonen, I'm a student of technical chemistry and I live in Vienna, Austria.

One of my hobbies is collecting and shooting military surplus guns. About one year ago I

read a chapter about "squib loads" in K.D.Meyer's "Handbuch

für den Wiederlader". I was so fascinated of the possibility to load subsonic

ammunition for a high power rifle that I started searching in the internet. Soon I found

what I was looking for: Lots of information related to that topic at the Gunwriter pages.

After printing out and reading the three parts of "Arcane" I started to roll my

own subsonics and reduced practice loads in 7,62 x 54R. Unfortunately I do not have a

chronograph at home so I will have to take my rounds out to the range of the proof house

to measure muzzle velocity. The powder I use is Kemira N310, I followed your advice and

widened up the priming hole of the "special purpose" brass to 3 or 3.5 mm.

Ignition of the powder seems to be more constant now. Once I tried cotton wad to hold the

small amount of powder near the primer but results where really awfull. Every time I fired

my Mosin M91/30 a smoldering cotton ball came out of the muzzle and landed some meters in

front of me in the dry grass. As I didn't want to set the range up on fire I stopped

adding the cotton. Widened up flash holes are much better than putting wadding over the

powder!

I read the "Gospel according to Marcus" and noticed, after some calculation,

that the efficiency of a rifle is not a constant. I'm not an expert in inner ballistics

but these calculations require nothing else than little knowledge in physics and physical

chemistry. It is true that the highest level of the efficiency can reach up to 32 or 33%

in a rifle, but that's with high powered loads only. A subsonic load won't reach that

level!. That's similar to other heat engines, like the Diesel engine: Higher pressure

means higher efficiency. As you know the Diesel engine works with much higher pressures

than the "Otto motor", it therefore has a higher grade of efficiency.

An example:

(All load and velocity data from "a Gospel according to Marcus")

Load1: Lapua 123 gr (7,97*10-23 kg) bullet, 0,42 g Kemira N310 (4200 J/g of heat energy,

as we know); velocity measured: 296 m/s

Calculation of kinetic energy of the bullet:

Ekin = ˝ mv2

Ekin = ˝ * (7,97*10-23) * 2962

Ekin = 349,167 J

Energy from 0,42 g N310:

1 g gives 4200 J, so 0,42 g give 4200 * 0,42 J = 1764 J

And finally:

1764 J.............100%

349,167 J........x %x = 349,167 * 100 / 1764 = 19,7940 %

Efficiency of that round (in Markus' rifle) = 19,8 %!

Let's compare it to another load with same bullet but higher amount of same powder:

Load2: Lapua 123 gr (7,97*10-23 kg) bullet, 0,91 g Kemira N310; velocity measured: 563 m/s

Calculation of kinetic energy of the bullet:

Ekin = ˝ * (7,97*10-23) * 5632

Ekin = 1263,18 J

Energy from 0,91 g N310:

1 g N310..........4200 J

0,91g N310......x Jx = 0,91 * 4200 = 3822 J

And finally:

3822 J.............100%

1263,18 J........x %x = 1263,18 * 100 / 3822 = 33,05 %

Efficiency of that round = 33,1 %!

So, as a rule of thumb, one can say the subsonic cartridges (with jacketed bullets) have

about 2/3 of the efficiency of a high powered round (same gun, same bullet,.... and so

on).

If you calculate it from the other way round; say: velocity wanted : 300 m/s, bullet

weight: 123 gr, efficiency of my rifle: 32 % and energy of powder: 4200 J/g, your result

will be less powder than what you will really need. If you calculate it again with 20 %

efficiency of the rifle, you'll get about the correct amount of powder and therefore the

300 m/s and not the bullet lodged in the bore.

I would be pleased to read your opinion! Best regards and happy shooting!

John. from Vienna, Austria

and comment:

It is pleasant to see that some educated visitor has interested in efficiency of special

handloads. Have you found my article about the birth of Secondary

Explosion Effect/ Reduced Charge Detonation from GOW website? Your comments are

welcome! I think, just like you, that firearms are nothing but internal combustion engines

- or "machines for throwing projectiles" according to Oliver Winchester.

I've published some calculations re firearm's efficiency by GOW/Finnish page: Test rifle

of Markus was able to generate 31 - 32 % efficiency before shortening if it's barrel when

his pet load 0.66 gram of N310 was discharged with bullets weighing 4.7 to 8.0 grams. Most

efficient were those shots with lubricated bore and/ or bullet. Pre-heating of the bore

shall also enhance the efficiency somewhat.

I know principle of Diesel engines, starting from thermo-dynamic calculations of French

scientist Sadi Carnot, who predicted design of highly efficient internal

combustion engines several decades before Rudolf Diesel was able to realize "grey

theory" of Carnot and show that his calculations about efficiency of engines were all

correct.

During the era of Carnot, another Frenchman, metal worker and inventor Lenoir was designed

a combustion engine, patented in 1860, using the coal gas as it's fuel. Mixture of gas and

air was not compressed in the cylinder of Lenoir engine. Actually, there was a pressure

0.9 to 0.95 atmospheres (a partial vacuum) in the cylinder before electrical ignition of

gas mixture. (Similar ignition arrangement with a battery and Ruhmkorff's high-voltage

inductor was applied later for Henry Ford's T-Model car engines).

Efficiency of Lenoir engine was miserable: It's gas consumption was 3 cubic meters per a

horsepower in hour, while consumption of small-sized Otto & Langen/ Deuz gas motors

was 0.7 to 0.9 cubic meter per hph and large Deuz engines consumed just 0.5 cub.m. of coal

gas per hph. Design of Lenoir motor was based on a steam engine. Maximum cylinder pressure

was mere 5 to 6 atmospheres. It was, however, possible to run Lenoir engines weeks or

months "non-stop" before pauses for maintenance, and some small-scale industry

workshops or local small-scale electrical power plants ran still the engines several

decades after 1870, when Lenoir engine was declared to be "ancient and

obsolete". It was as silent as a steam engine and about as efficient (efficiency ca.

4 %). But it was tidy in use and did not need a risky steam boiler, steam tube and stoking

of boiler. The fuel of engine was coal, but it was not burned into the steam boiler: The

"essence" of coal came from a gas plant.

Gas engines of Otto & Langen (later Deuz motors) were considerably more

efficient because of pre-compression of gas & air mixture before ignition, to the

pressure 2˝ or 3 atmospheres. Maximum cylinder pressure was 11 to 13 atmospheres and

exhaust pressure was 3 to 3˝ atmospheres. Efficiency was at best 25 % when the coal gas

was of premium quality with calorific intensity 5200 Calories per cubic meter and gas

consuption of engine was 0.5 cubic meter per horsepower per hour.

Drawbacks of more efficient engines were noisiness and excessive heat. It was meeded to

design a muffler or silencer for the exhaust tube and a water-cooling jacket on cylinder

in about 1870. Considerably increased cylinder pressure strained also the bearings of Deuz

engine. Mechanical parts of Lenoir engine were designed to be everlasting. Just the piston

ring was necessary to become replaced annually or bi-annually, if the engine was running

24 hours per day, seven days per a week.

This educational story was published on the Finnish "Book of Inventions, Vol.

2." by Wihtori Peltonen in 1908. Low efficiency of subsonic or Economy rifle loads is

not a drawback, since it shall continue the useful life of a rifle bore to the infinity.

Less heat = less wear, because thermal erosion shall deteriorate the rifle bore. Cartridge

cases may also stand several hundreds if not thousands of reloadings and shots.

"Waste" of the powder is not too many milligrams per shot if the charge burns

completely in the bore.

The powder, generating subsonic bullet velocity (V max. 305 m/s) by a high chamber

pressure is needed, but it'll have very limited use. N310 is, on the other hand, very

versatile. Presumably any and all rifle cartridges between .22 Short rimfire and 20 x 138

mm Solothurn Long are possible to load with N310 for subsonic velocity level. This same

powder is also applicable for handgun and shotgun loads.

There was actually a suitable powder available in past, known as E.C. Blank Powder,

generating subsonic velocity for 123 grains jacketed bullet in .308 Winchester rifle with

a chamber pressure ca. 4000 atmospheres and 33 % to 35 % efficiency. Manufacturer of this

powder, Explosives Company, warned that "no projectile, other than a thin cardboard

top-wadding, should be loaded to the cartridges on the Blank Powder charge!". There

were, however, Danish Schouboe pistol cartridges loaded with E.C. Blank and steel-jacketed

bullet with wooden core and aluminium base plate. Bullet weight was 3.1 or 4.0 grams.

Schouboe pistols were self-loaders with a plain blow-back action.

Caliber of them was 11.35 x 18 mm. Muzzle velocity of light bullet was a lot more than 500

meters per second. Velocity of a bullet, weighing 4.0 grams, was ca. 480 mps; measured

presumably with a ballistic pendulum. Pistols were designed since 1903 until 1917, but no

armies (even Danish) were interested in them, because they were "lacking accuracy at

long ranges and the Stopping Power". Previous and more succesfull invention of Jens

Torring Schouboe was a Madsen light machine gun, produced since 1904 until late 1950s.

For your calculations I should offer some additional up-to-date information: Calorimetric

energy content of VV N310 powder, 3200 Joules per gram, is just an approximate value

published on "Reloading Manual" of VihtaVuori; printed in January 2000. Many

recent lots of N310 contains 3150 Jpg of heat energy, according to H.Broemel's QuickLOAD

ballistic program.

Barrel length of .308 Sako Varmint test-rifle of Markus is shortened to length 46

centimeters when the rifle was equipped with a suppressor (or actually a true SILENCER,

when the rifle is loaded with truly subsonic cartridges). Loading data for

"Gospel" was tested with long-barreled rifle, before mounting of suppressor.

Original barrel length was 66 centimeters.

The QuickLOAD program is able to predict powder charges needed for cartridges (loaded with

known components) very precisely; within few milligrams. It can also predict average

velocity for known combination of handloading components (shot from known rifle) sometimes

with less than plus/minus one meter per second error.

QuickLOAD is able to give the most precise predictions for Economy loads with quickly

burning/ easy-to-ignite powders like VihtaVuori N310, but it is unable to foretell

consequences of variable jacket hardness & friction or variable "bore

condition" (= temperature/ lubrication). Program is also unable to predict suggested

starting loads or definitive minimum charges. Therefore the chronograph is still essential

instrument for serious researcher of highly special handloads. (Can you believe that

Markus is now just sixteen years and nine months old? Age of an apprentice but competence

of a Master Ballistician).

VihtaVuori Oy is no more a subsidiary of Kemira Oy but Norwegian NAMMO corporation.

Powders are marketed as VihtaVuori propellants, abbreviated as: "VV". "Old

Guru" K.D.Meyer was my instructor like yours: I have also a book "Handbuch für

den Wiederlader" and in late 1970s I was corresponding with K.D. Actually, he incited

me to start research of Economy and subsonic handloads. He told that Finnish N320 powder

has most of itscharacteristics similar to German Platzpatronen Nz-Rohrpulver "Sorte

33", loaded into 7.9 mm Finower Nahpatronen (subsonic loads for suppressed Mauser

Modell 98 k rifles). K.D. was a co-designer of Nahpatronen in 1942 - 43.

I obtained an Oehler Model 12 chronograph in the late 1980 and wrote an article about

reduced charge handloads for .308 Winchester rifle in 1981, but the story was published

not until December 1982: "Revolution of handloading" was started in Finland. It

is still continuing and extended all'round the World.

2409 MM; PT

Subsonic .223 ammo

Fantastic site! I sat and red till my eyes bled. I loved it!! Recently I have come across

a company whom sells subsonic .223 ammo that they claim will cycle semiautomatic firearms.

I can also purchase subsonic ammo for a bolt action rifle, the problem is, the ammo sells

for about 2 $ (US) a round. Of course they won't tell me how to load my own which is

understandable... I am mostly interested in ammo for my bolt action .223 rifle: FUN! FUN!

I would like to know how to manufacture them without blow-up. Sorry that my spelling and

typing is not the greatest.

Standing by yours truly, Mark

Your spelling

& typing is not the most horrible, I've seen. I did, however, some edition and

revisions, as usual. Some Finnish visitors also spell and type lousy Finnish. A little

minority of questions arrives to GOW sites without any need of proof-reading and

revisions.

Handloading of subsonic .223 Remington cartridges is not difficult or hazardous, if the

powder used is easy to ignite. (Not some usual rifle powder). Recommended propellants are:

Hodgdon Titewad, Norma R1, VihtaVuori N310 (pet powder of Finnish "supu

loaders"), Alliant Bullseye, Scot Solo 1000, Accurate Arms No. 2, Alliant Red Dot,

Hodgdon Clays (original Australian AS-30N), VihtaVuori N320, Scot Royal and Hodgdon HP-38.

(Russian Sokol Porokha is unavailable in West. Therefore the dozen is short). Some more

advanced handloaders in USA are using powders, as slowly burning as Alliant's Unique or

Hodgdon's Universal for .223 loads, along with heavier bullets.

Recommended bullet weights for beginners are 50 grains or 55 grains. Recommended bullet

brand is Sierra: Hardness and bore friction of the jacket metal is uniform. You should

clean all the metal fouling away from your rifle bore before shooting of "supu

loads" (= cartridges generating subsonic bullet velocity). Starting load is four (4)

grains of powder for a bullet weighing 50 grains, or five (5) grains of powder for 55

grains bullet. Lubricate the bore of your rifle (lightly) with some oil before shooting.

"Break-Free" oil is good for purpose. Shake the can before application of

lubricant.

Listen the noise of report: If it is just a dull "BANG" coming from the rifle

muzzle, your load is subsonic. If it is a more shrill "CRACK", coming from the

direction of target (not from your rifle), the bullet velocity is trans-sonic or

supersonic. You should reduce the powder charge one tenth of a grain for next batch of

cartridges. (Those eleven recommended brands of powder have about similar

"flammability" but different energy: N310 shall generate a Calorimetric Energy

4150 Joules per gram, while Alliant Bullseye may generate ca. 5100 Jpg, and accordingly

higher bullet velocity, when the charges are equal).

If the velocity is still trans-sonic (= some cartridges "bangs" while some of

them "cracks"), you should remove another 1/10 grain of powder from your next

batch of cartridges, et cetera, until all the bullets are flying without a "whiplash

noise" or "ballistic crack". Every batch must be at least five rounds of

cartridges. It is beneficial to keep the "bore condition" constant by

lubrication of bullets; even the jacketed ones. Bullet producers are already making more

slippery bullets by coating them with silvery-grey Molybdenium Bi-Sulphide, but it is easy

to lubricate the bullets by dipping them into some lubricant, like melted neat's fat.

Commercial cast bullet lubes (like LEE Liquid Alox) are good also for lubrication of

jacketed bullets. The dip-lubrication of bullets should be carried out after seating of

them into the cartridges, not before, because the greasy or wax-lubricated bullets are

somewhat messy to handle.

0909 MM; PT

Handloads for .43 Spanish (once again)

Thank you for your friendly E-mail. This is the result of my trying to use starting load

data of .45-70 Trap Door as appeared in Ken's Pet Loads. Neither Finnish powders nor IMR

are available in my country. Really: Nothing is available in Spain. Thanks God: France is

50 miles from my home. So I've tried with Vectan. Where I can get the loading program?

Saludos; Jorge.

If you

have found handloading data for .45-70 Government cartridges with Vectan powders, you may

use the same charges with (about) the same bullet weights for .43 Spanish too. (Data for

Trapdoor Springfield Model 1873 actions, of course). Many contemporary military

cartridges, like 10.75 mm Russian Berdan and German 11 mm Mauser Model 1871 have a loading

data equal with .43 Spanish or .45-70 Government Model 1873, even with the smokeless

powders. Vectan powders are still unknown propellants to me. I have not Broemel QuickLOAD

program in my possession. You may ask from our test-shooter Markus (MPP), whether there

are loading data for .43 Spanish or .45-70 cartridges with Vectan (SNPE) or some other

French powders in the program, and also the German source, from where you can get the

QuickLOAD/ QuickTARGET program. E-mail address of Markus is: markuspnk@hotmail.com

Nota Bene: Four Vectan rifle powders are listed as SNPE powders in Broemel QL program.

Saludos; 0709 MM; PT

.22 LR suppressor

Dear Mr Pete: Thank you for your e-mail. I have made suppressor: Length 145 mm, diameter

31 mm with 6 baffles. It works very good. This suppressor make very quiet metallic clink.

I have two more very important questions:

1. What shall happend if I add 4 baffles more?

2. What shall happend if I make bigger primary expansion chamber for example 10 - 20 %

more? (Now is length 60 mm, diameter 31 mm). No changing number of baffles.

I am very worry about problems with your Website. I hope that everything will be allright.

Emil (Poland)

&

comments: Congratulations! You have designed a well balanced device; not only a suppressor

but a true silencer!

1. Additional baffles are unable to improve silencing effect of your device, because

they'll reduce a gas expansion volume inside the silencer jacket. You should add one

centimeter to the jacket length for each additional baffle and spacer. I presume, the

silencing effect shall not become improved. My short model suppressor prototype of Humbert's

design had just 5 baffles, but it was mounted on the long-barreled TOZ Model 8 rifle.

Silencer for short-barreled rifle must be as big as your's design. My five-baffle

muzzle-can was drilled from a solid aluminium bar, diameter 25 mm. Inside diameter was 20

mm. There were nylon baffles 5 mm thick and and spaces between them were also five

millimeters. Spacers were of aluminium sheet, @-shaped.

TOZ 8 rifle had a non-tapered barrel, thickness 20 mm and a sturdy front-sight base. So I

could use a slip-on bayonet-mounted suppressor. It extended 170 mm ahead of a rifle

muzzle. Diameter of bullet passage apertures was mere 7.0 mm. Silencing effect was as good

as that of original Finnish SuoMet suppressor with a helical-groove spiral diffuser. I

donated my prototype to SuoMet Oy (later Vaime Oy; still later Laxmit

Metal Oy). A Japanese-born friend of mine, Mitsuo Taguchi, completed the

construction to become applicable also for the short-barreled firearms and full-powered

centerfire rifles. Mitsuo was able to protect his improvements by a Finnish Patent.

2. More large (lengthened) primary expansion chamber may reduce the silencing effect,

because of increased "gas blow-by" and "precursor wave" (a gas stream

flowing past the bullet inside the expansion chamber). Your silencer design needs no

improvements. You may try to reduce the metallic clink by coating the silencer jacket with

rubber (by slipping a piece of inner tube of a bicycle tire on the jacket tubing), but the

clink is actually a very short-lasting "whistle" of powder gasses in the spaces

between baffles. It is presumably no more loud than is a snap of rifle striker or hammer

on the empty chamber. Being a high-frequency (shrill) sound, this clink is audible within

no more than 100 to 150 meters, and it is very difficult to identify a "short

whistle" as a report of the rifle.

0709 MM; PT

More >>

<< New Q&A More Q&A, part 7 >> Part 6

>> Part 5 >> Part

4 >> Part 2 >> Part 1 >> Gunwriters

guns.connect.fi Link page