<< Newest Q&A

More Q&A, part 4 >> Part 3 >> Part 2 >>

First Q&A, part 1 >> Gunwriters

Link page

Custom Search

Part 5, questions and answers until 26.01.2000

G.O.W. Kickback:

Questions and Answers, part 5

Answered by: P. T. Kekkonen

Aguila SSS

(SubSonic Sniper) 22LR Ammo

Aguila SSS

(SubSonic Sniper) 22LR Ammo

Hi Pete! I've recently purchased a quantity of subsonic 22 ammo manufactured in Mexico

under the 'Aguila' name by Industrias Technos of

Cuernavaca. The firm is partially owned by Remington Arms.

The ammunition (see Gunwriters' archive image at

left) is of unique design, being essentially a

22Short case mounting a 60 grain lead bullet (20 gr heavier than the common 40 gr solid

bullet in most 22LR's) with a velocity of about 900 fps. Bullet length is half again the

length (visable) of the casing. The story I get from the supplier is that the round

was originally designed for use as sniper ammo for jungle warfare, hence the name

'SubSonic Sniper' that kept the shipment sitting in a US Customs warehouse for several

months while the beuracrats messed around with whether it was 'military application only'

and prohibited. The stuff is selling at an accelerated rate at gunshows nationwide

since the import red tape has cleared up. It is about as loud as a 22CB.

I've shot the stuff through every 22 I own and those of a couple of friends, it functions

well in autoloaders, both rifle and handgun, as well as bolt actions and revolvers.

Accuracy is generally as good as the weapon being used with two exceptions: the

long-barrel bolt actions (Mossberg and Radom) both with 25 inch barrels, keyhole the

bullets past a range of about 30 meters on a consistent basis. Is this the effect of twist

in the long barrels upon the elongated 60gr bullet? Interestingly enough, even with

keyholing, accuracy dosen't suffer, the bullet-strike is sideways, but on target.

I'd be very happy to hear any comments you have regarding this ammunition, and whether you

have any further information on it from other sources. Thanks, I very much enjoy your

articles.

Ziplock

I have no personal shooting experience with .22 SSS but our

test-shooter Markus has test-shot 30 rounds of them and another friend of mine shot also a

"preliminary test" to see, whether those cartridges are safe to shoot through

the Parker-Hale's "Sound Moderator MM1", mounted to a Russian TOZ Model 17-01

rifle (with barrel length ca. 10 inches). They were. Markus has also TOZ 17 rifle, made in

1961, nowadays with the real silencer of BR-Tuote and

hand-lapped bore, with a barrel length ca. 17 inches. I got a box of 50 cartridges from

USA as a X-mas present few weeks before Seasons and donated them for a most useful

purposes I can imagine, because I have no .22 LR firearms in my possession, but just one

12.17 x 44 mm R Swedish Remington rifle, made in 1875 and so allowed to possess without

any licence from "The Piggery". (Firearms, made before 1890, are "curios or

relics" according to Finnish firearms legislature).

Markus has shot three-shot groups, average size .35 inches at 25 meters, in the indoor

range (we have wintertime in Finland), without a real bench rest available. Accuracy seems

to be about equal or slightly better than that of Finnish Lapua Scoremax .22 LR. Aguila

SSS is TRULY subsonic, while Scoremax is trans-sonic when shot from rifles with 16"

barrel length or even supersonic, if shot from (say) 10" barrel of silenced rifles or

handguns. In Finland is not a minimum barrel length at all for .22 rimfire shoulder arms,

but a demand for overall rifle length must be about similar to the minimum O.A.L. in USA,

when the silencer is mounted.

Penetration of Aguila SSS bullets was more deep than usual .22 LR solid 40 grains bullets

or that of .22 LR Scoremax, despite of the fact that 60 gr SSS bullet yaws soon after the

hit on a dry paper pack used for penetration test media, and lost almost 50 % from it's

weight. According to test report of Markus: The bullet of SSS acts as a "furtive

DumDum" bullet soon after a hit, but as a real DumDum bullet of .303 British Mark II

Special cartridge after the deeper penetration. In the actual soft tissue, the 45 + per

cent fragmentation cannot, of course, exist, because of the low striking velocity, but the

yaw-effect is able to cause all that tissue destruction, available with a kinetic energy

or the striking momentum. (Kinetic energy = velocity x velocity x bullet weight per a

gravitational constant. Momentum = velocity x bullet weight).

Rifling twist of TOZ rifles is difficult to measure, because the four rifling grooves are

narrow and lands are broad, about two times as broad as the grooves. Bore and groove

diameters are usual (bore dia. 5.50 mm, groove dia. 5.70 mm), but because of wide lands,

the bore shall squeeze bullet tightly and concentrate it well into the bore. (If the

grooves and lands are equally wide, the bore diameter of really accurate barrel must be

5.40 or just 5.30 mm. Diameters so small are usually met in old rifles, made before year

1914, when European C.I.P. standards were adopted, with allowed minimum bore diameter

5.50. Austrian-made Voere rifles have, however, 5.4 mm bore diameter and splendid

accuracy). Chamber of TOZ rifle is also shorter than usual. Length for the .22 Long

(Rifle) shell chamber is as usual (14.8 mm) but the rifling starts after ca. two

millimeters distance from the mouth of chambered case. Closing movement of the bolt pushes

the bullet's rearmost "rotation ring" into the rifling, engraving four clearly

visible rifling marks on the bullet's shank.

TOZ rifles are very accurate firearms, if there is not a burr (made by a dull chambering

reamer) ahead of the chamber. This burr is easy to remove by hand-lapping. I don't know,

whether it is possible to shoot the burr away by so-called "firelapping",

because the fault is usually found by gauging with a lead plug, and lapped away with the

same lead rod, covered with emery powder and grease or valve grinding paste. Abbreviation

TOZ comes from name: "Tulskiy Oruzheiniy Zavod" = Arms Manufacture of

Tula".

I've possessed three TOZ rifles since mid-1970s (later sold or donated away), but I'm

almost ignorant about the rifling twist. I chopped the barrel of my first single-shot

TOZ-8 down to the length 150 mm (less than 6") before mounting of a long & rather

fat silencer. I could note that rifling made almost exactly a half rotation from the

chamber to muzzle. Twist might be therefore 300 millimeters (less than 1 - 12 inch). Usual

twists of .22 LR bores are 14" to 16". In Finland were made in late 1970s some

experimental barrels with 1 - 20" for shooting of High Speed cartridges only, but it

was soon found that Hi Speed ammo is not suitable for competition shooting ("running

boar" or "biathlon") at all. Those experimental barrels with 1 - 20"

twist were presumably never sold. Fruitless tests with them were ended, as far as I can

remember, in 1978. Manufacturer of them, Tampereen Asepaja Oy, has been out from business

more than a decade.

Your Mossberg and Radom rifles may have 1 - 16" twist. My simple calculations told

that 1 - 14" may be "marginal" and a twist 1 - 12" or less is needed

for gyro-stabilization of overly long bullet. I have "optimized" the .22 LR

subsonic bullet weight while designing a special TRURY subsonic cartridge for autoloading

firearms in 1992. Optimized bullet has the weight 50 grains (to become stable in ALL

existing riflings) or some 47 gr of a "stuffed hollow cavity" projectile. Not

explosive one, since the tried explosives may cause "duds", but good old mineral

jelly (vaseline) filling never fails to expand the bullet. Neither .22 Long nor .22 Short

case is good with 50 gr bullet, shaped for positive feed in autoloaders (including belt

fed miniature machine guns, shooting 1200 rounds per minute).

I forwarded my idea to Lapua cartridge manufacture in December 1992, but Lapua adopted

just the heavy projectile, ill-shaped for the autoloaders, because seated in the .22

Long/LR case and must therefore have too blunt point. Bullet of Lapua Scoremax is also

smeared with "tacky lube". It's muzzle velocity is O.K. for competition rifles

with 26" barrel length, but if the barrel is more common, with 16" to 22 inch

length, is the available velocity transsonic, and when shot from more shortened barrel of

silenced rifles (common in Finland), the bullet gains supersonic velocity. A silencer is

then needless, because the bullet's flight noise is more irritant and loud than the muzzle

blast of non-silenced rifles.

.22 LR Scoremax is designed like most of Lapua's .22 LRs (all those velocity-tested in 660

mm barrel length) to be good for "Finnish Lion" competition rifle with a long

barrel, bolt action, without a magazine at all. It is almost "silent without

silencer", when shot from a competition rifle, but majority of .22 LR rimfire rifles

are "utility guns", and many times autoloaders. I made the new cartridge

drawings for Remington in the mid-1990s. They also adopted the heavy bullet.. too heavy

one.! Many thanks to you for the information on the collaboration between Remington and

producer of Aguila cartridges !!! I presume that .22 SSS is designed by Remington, but

because of some unknown (political ??) reasons, it is impossible to yield .22 AutoLoader

Subsonic ammo in USA. (Use of "silent without a silencer" cartridges or loads is

a way to evade that lousy "Lex Morgenthau"/Federal Firearms Act 1934, without

violation of it, and so hold it up to ridicule. My idea was to load these .22 ALS

cartridges into the shortENED cases, but .22 Short cases may become utilized "for the

preliminary test-shootings, when the flight stabilization of extra-heavy bullet is needed

to test with various rifling twists by trial-and-error method".

Suggested .22 ALS cartridge was based on intermediate-length case, entirely novel one,

with a length 13 mm (= ½ inch, or half from the overall cartridge length, when crimped on

the bullet's heel). Designers of .22 SSS adopted, however, .22 Short case, which is found

to be somewhat too short, while the bullet is accordingly too long to become gyro-stable

in flight. My slogan was: "Functioning in ANY AND ALL firearms chambered for .22 LR

ammo". Designers of .22 SSS designed also a special rifle with extra-steep rifling

twist for shooting of these special "For Official Use Only" cartridges. One

characteristic of .22 SSS is pleasing me: Bullet velocity is TRULY subsonic.!!!

According to tests recently carried out in USA, SSS cartridge gives the maximum velocity

from 10 inch barrel length. My suggestion was to use 300 mm test-barrel with a tight

"Target" chamber and a mirror-bright lapped bore. Maximum bullet velocity might

be 300 meters per second, or 1000 feet per second; no more. If the barrel length is more

or less than 300 millimeters, the bullet velocity shall be less than maximum, and not even

trans-sonic in any conditions. It is easy to reach 1000 fps for 50 gr bullet without

overly high chamber pressure, if the powder charge is loaded into ½ inch case. The .22

Short case simply cannot hold enough powder, Q.E.D.

My original suggestion to Lapua Oy was based on our "Bullet

Velocity vs. Flight Noise" test-shootings, carried out in the early summer 1992.

We found the trans-sonic velocity level during our scientific studies, done 110

years after those of professor Ernst Mach, who had not yet the instruments

sensitive enough to find out the transsonic noise of projectiles. We had. Professor Mach

discovered in 1880s so-called "sound barrier" and he photographed the "bow

waves" of supersonic as early as in 1883. We continued his research work, and some

cartridge manufacturers are seemingly paid attention to our findings, published by several

technical periodicals and a book "Silencer History

and Performance, Vol. 1" by Alan C. Paulson. (See table on the page 70).

My suggestions and drawings, addressed to then-director of Lapua Oy, were never forwarded

to the product developement division of Lapua factory. Somebody, next from the director on

the hierarchy, thought those innovations to be once again: "The horrible products of

a brainstorm, designed seemingly to become pets of poachers and assassines".

Waste-paper basket is the usual grave of "N.I.H." suggestions. (= Not

Invented Here). When the .22 LR Scoremax cartridge was designed several years later,

the primary demand was - seemingly - that it must be as UNsuitable for autoloading

firearms as practicable to make.

Third set of suggestions and drawings were sent to Brazilian C.B.C. (manufacturer of

low-priced ammo), but once again without success... But now back to your problems with

long-barreled rifles Mossberg and Radom: A notable fault of .22 SSS is too thin (if any)

lubrication of the extra-long/extra-heavy bullet. The projectile acts as a

"compression bullet" of military rifles in 1850s to 1870s, including many early

breechloaders. A sudden thrust of chamber pressure expands the bullet into the bore. It is

beneficial for accuracy of shooting, but tends to cause leading of the bore; especially in

the muzzle end of barrel with a length more than 24"/ 61 cm.

Lead fouling may cause the "precession" (yaw) of bullet, already just marginally

stable because of too slow rotation. If the rifle shoots nice round holes to 50

yards/meters when cleaned, but starts to produce the "keyholes" after a dozen of

shots, the lead has accumulated into the bore. You may try to "dip lube" the

bullets in a melted bullet lubricant - or actually almost any fatty substance.

("Patent Medicine" of G.O.W's Technical Editor/Test Shooter Markus is the

purified neat's fat, sold as a shortening for cooking of Pommes Frités/ potato

chips in Finland). Bullets of .22 SSS have ample "cannelures" or lube grooves

knurled around to receive the dip lubricant.

For .22 ALS (originally .22 LASS = Lapua Autoloader SubSonic) bullets I suggested metal

plating with copper or cadmium, which is inherently "slippery" coating metal. It

was also suggested to plate the cartridge cases with cadmium. The same suggestions were

addressed also to Remington and C.B.C - without notable success. I have not yet abandoned

that "LASSIE Project", but I am lacking e-mail address of Klimovsk

cartridge factory in Russia and Norinco in China: "Ex Orient Lux.?!"

Russian cartridges may have steel cases. If plated with cadmium, they'll become ejected

reliably from the autoloading firearms, without too tight adhesion into the chamber.

Shortened length of the case shall also lessen the case adhesion.

I have shot ca. 7500 rounds of Russian Vostok Sport & Hunting .22 LR

cartridges with phosphate coated steel cases (known as "Black Russians" because

of dark grey color; almost black, when lubricated) from as "impossible" rifle as

Remington Nylon 66 autoloader, without feed or ejection jams or misfires, when I learnt to

rub the cartridges between the palms of my hands before dropping them into the buttstock

magazine of that "guttapercha gun". (Old folks in Finland call all kinds of

plastic as "guttapercha" - including, of course, Carother's "Polymer

66"). Bullets of Vostok S & Hs were greased heavily with the tacky lube,

which was easy to smear on the cases.

Phosphate coating (Parkerizing) made the cases very slippery and easy to eject, despite of

overly heavy breech-bolt and linear hammer of Remington rifle, needing more than 800

gram-meters per second of momentum for complete automatic cycle and cocking, even if the

case is of resilient metal. Shooting was somewhat messy bustling, but in 1970s "when

my heart was young and gay", I didn't took care of lead poisoning or other risks of

hobby. Entirely metal-plated cartridges are, however, "must" for the autoloading

firearms, and I presume, the cadmium plating don't wear away from the bullets.

I donated the .22 SSS cartridges to the test-shooters, because I am never more entitled to

possess (legally) any modern firearms or ammo. (In Finland the "gunwriter" is a

person who is entitled, or actually privileged, to write articles for the PRINTED media. I

am "black-listed" by the publishers of ALL Finnish periodicals. Finnish

"Freedom of the Press Law" don't know the existence of Internet at all. It was

enacted in the year 1919. The predictable next step is to extend our strict censorship and

"black-listing" to cover also the Web-media). My "prima vista"

impression was that bullets of .22 SSS cartridges are unlubricated and unplated, just like

the lead pellets of compressed air or carbon dioxide rifles and pistols..! If so, the

skill of dip-lubrication or home-workshop metal electroplating is needed. I'll try to

learn those useful tricks, by words and drawings.

2101 MM; Pete

"I HAVE A DREAM.!": Subsonic .22 LR for autoloading firearms.

Actually it is not a .22 LR, with it's case length simply too long, but the usual .22

Short case is not long enough. Experiences from the current Lapua Scoremax .22 LR and Aguila .22 SSS shows that my idea is not just "a

grey theory". Original suggested name of INTERMEDIATE-SIZED case was .22 LAPUA, and

the suggested name abbreviation of a cartridges, loaded in those cases was .22 LASS

(Lapua Autoloader Sub Sonic), but later I re-christened my "brainstorm" as

a .22 ALS (Auto-Loader Subsonic) and the special case as .22 AL (Auto-Loader),

since there were case sizes called "Automatic" designed by WINCHESTER and

REMINGTON in the early 20th century. They had a diameter similar to that of modern .22 WMR

case, because it was essential that usual .22 Long or LR is impossible to shoot from early

autoloading rimfire rifles, since the usual cartridges were loaded with sooty blackpowder

or LESMOKE powder. And copper was not uncommon rimfire case material in those days.

The concept cartridge above might be a subsonic .22 LR in year

2010. It is a combination of P. T. Kekkonen's "ALS" concept and the M/2030 type cartridge with a primer igniting against a solid pellet

of compressed powder (Monoblock powder). Resulting all base primer will work

equally easily in rimfire .22LR weapons and with cheap cartridge chamber adapters in 5.6

mm centerfire rifles like .222 Rem, .223 Rem, 5,45 x 45 etc. Blunt nose is suggested by

Mark White of Sound Tech by his experiences with wildlife managemant to improve terminal

ballistics of the subsonic bullet. See also Mark White's article

about the topic.

In the early summer 1992 I was a member of Finnish researcher team, studying flight noises of subsonic, trans-sonic, supersonic and

hypersonic projectiles. I handloaded all of the .308 Winchester cartridges to the velocity

levels needed, from 162 meters per second to 1200 mps muzzle velocities (532 to 3937 fps).

See the table of velocities at 23 meters from the muzzle from page 70 on the book Silencer History

and Performance, Vol. 1 by AL C. PAULSON. Our finding was that majority of available

factory-loaded "subsonic" cartridges were too heavily loaded, giving transsonic,

and many times even supersonic, velocities from the suppressed .22 LR rifles with

shortened barrels (10 to 14 inches; usual in Finland, because here is just a minimum

overall length but not minimum barrel length given for .22 rimfire rifles in Finnish

Firearms Act). So I suggested Finnish LAPUA cartridge manufacture to adopt a foot-long

test barrel (300 mm) for test-shooting of subsonic .22 LR, instead of usual 660 mm (26

inch) velocity and pressure test barrel - but in vain...

I had previously a nasty experience with Lapua .22 LR "Subsonic" H.P.

cartridges, when I had handlapped or fire-lapped the bore of a Sako rifle, with 250 mm

barrel length and almost 500 mm long silencer - with an intention to improve the accuracy.

After the lapping was accuracy O.K. (less than 25 mm five shot groups at 100 meters =

3/4" at 100 yards) but the inherently efficient suppressor (truly a silencer) had no

more silencing effect at all. Bullet velocities were measured: HELL's BELLS ! Average: 355

meters per second ! Ambient temperature was +19 degr. Centigrade. Sonic velocity: 343 mps.

It was essential to enlarge the rifle chamber from it's Target dimensions to the common,

exceedingly large, C.I.P. Standard diameter. (C.I.P. or European standards are usually

ratified in 1914..!).

Fortunately enough, the accuracy of a rifle suffered not too much: Groups were 1.2"

to 100 meters, or somewhat more than one Minute Of Angle. Average bullet velocity was now

330 m/s; still trans-sonic, but no more too noisy in flight, and decreasing after emerge

to the ambient air. When shot from 26" barrel, were (and are) the muzzle velocities

of "subsonic" Lapua's .22 LR bullets, including those of Scoremax, 315 meters

per second (1034 fps). Jess; it is a subsonic velocity.! But who is fool enough to kill

the rats on a dumping-ground with a silenced "Finnish Lion" competition

rifle - in the country, where barrel length of a .22 rimfire rifle may be (legally) mere

two inches, if the silencer's length is 15 to 16 inches ? Barrel length of a silenced

"rat slayer" is usually less than a foot.

All of Lapua's .22 LR cartridges (with the exceptions of .22 LR Pistol King, Pistol

Trainer and Polar Biathlon) are designed for "shooting from a

competition rifle with 26" barrel, because only legal use of .22 LR cartridges is

competition shooting, or training for the shooting events. The Match Grade rifles have a

bolt action and not the clip or magazine at all"! I was not yet aware of this

"factory policy" in December 1992, when I sent a letter, containing essentials

of my .22 LASS project to the director of Lapua Cartridge Factory. He was interested, but

some "old farth" below him, on the ladders of hierarchy, was not. My suggestions

never met the actual cartridge designers of Lapua - as far as I know. And I know VERY

far..!!

My idea was based on an intermediate-length case, because .22 Long/LR case is designed in

1870 for revolver cartridges and in 1887 for rifles, loaded with black powder only. This

is the reason, why the smokeless loads of most .22 LR cartridges burns more or less

incompletely, leaving unburnt or half-bunrnt powder kernels into the bore or (especially)

into the suppressor: The case, designed to burn 5 grains of FFF-grade blackpowder behind a

29-grainer lead bullet in .22 Long or 40 gr bullet of .22 LR, is simply 1/10 inch too long

for the smokeless powders - despite of 110 years long evolution of these

"modern" propellants. (Yesh; the VERY original nitro-cellulose mixture, with

12.6 % of chemically bound nitrogen, is still an ideal powder for .22 LR cartridges. It is

an "all-weather powder": Functional as well in Sahara as in Siberia. A Russian

professor of chemistry in the University of Sant Petersburg - Dmitri

Mendelyeyev - discovered this mixture already in 1890!).

Length of .22 AL case is 13 millimeters before loading, and ½ inch when crimped around

the bullet heel, or about half from overall length of a loaded cartridge. Cylindrical body

of the case is ca. 20 % shorter than that of .22 Long (Rifle) case. So the friction area

and friction between the walls of case and cartridge chamber are 1/5 less, when compared

with .22 LR case. There are, of course, still more ways to reduce the case friction:

Cadmium electroplating of cases, dry-wax coating of them, or simply use of hard &

resilient brass (alloy 67 % copper + 33 % zinc) as a case material.

I don't know the consistence of copper alloy of Lapua .22 LR cases, but they were in

mid-1980s annealed to become less soft than the copper cases made by East German

Schoenebeck cases. Not good for autoloader firearms, but don't forget: They were made

for bolt-action single-shot competition rifles ONLY by allies of ex-Soviet Union. Rimfire

cases (say, for example) of Remington .22 CB Long cartridges are of hard and resilient

brass. If coated with dry wax (which may be done by dipping loaded cartridges into the

mixture of carbon-tetra-chloride solvent and solid paraffine wax, leaving just the

cartridge head unlubed), must the case and bullet be so dimensioned that the wax coating

on a cartridge cannot yet raise diameter too much.

Priorities of characteristics are as follows. Number one: Reliable (read: POSITIVE) feed

from all imaginable kinds of clips and magazines, including belts of "miniature

machine guns", and equally positive extraction, ejection and re-cocking of the firing

mechanism of any & all autoloading firearms, chambered for .22 LR cartridges. Number

two: TRULY subsonic bullet velocity, despite of barrel length, chamber diameter (including

narrow "Target" chambers), and slickiness of the bore. Number three: Stable

"arrow-like" bullet flight from the muzzle to the extreme range. Number four:

Shooting accuracy. Number five: Lethal effect of a hit.. (Read: Hits).

Contrary to the "sniping philosophy", a combined effect of multiple hits, is

appreciated by many shooters. A vast majority of hunters or pest killers are less skilled

marksmen and even the masters may have "bad day" or a bad luck. Then is a quick

follow-up shot needed... or shots. Effect of three successive hits is cumulative.

Lethality of a shotgun is based on multiple simultaneous hits of low-powered pellet,

usually not penetrating the vital organs of a living target, but still lethal suddenly, as

a strike of three-forked thunderbolt. Most shooters are able to learn a "triple

tap" with a supported or rested autoloader .22 rimfire rifle. Three hits during 1½

second is a sufficient rate of fire.

"When my heart was yong and gay" and my eyesight was still keen (in early

1980s), I was able to shoot 14 shots from a rested feather-light Remington Nylon 66

autoloader during ca. three seconds - sometimes all the hits within ca. 30 millimeters

ring and usually within 1½ inch circle at 100 meters. Easy with a rested rifle, even

light one. Off-hand shooting I have never learnt, but those

"kuularuisku-demonstraatiot" (machine-gunning shows) attracted notice on the

public shooting range. I had a suppressor mounted on my own Remington, but the cartridges

used for those demonstrations (brand VOSTOK Sport & Hunting, with a phosphate-coated

steel case) gave transsonic or supersonic velocity and accordingly more or less loud

bullet flight noise.

Most accurate cartridge was Lapua Sound Moderator Hollowpoint, which gave

subsonic bullet velocity, but it was able to blow the overly heavy breech-bolt of

Remington back no more than .1 or .12 inch. Firepower was, however, satisfactory if

compared with a bolt-action rifle, and the dominant shooting signature was snap of the

heavy linear hammer inside the hollow plastic stock of that rifle. The brass case,

annealed "dead soft" (actually softer than the copper shell of contemporary

Schoenebeck .22 LR cartridges) prevented autoloading, along with a rather low

"momentum" of Lapua SMHP load. Bullet weight is 2.4 grams (when the deep

point-cavity was filled with mineral jelly/ Vaseline, which is more effective way to

enhance "DumDum effect" of that bullet than was use of real

shock-sensitive explosive. I tried mixture of potassium chlorate and black antimony

sulphide, sometimes made more sensitive with added glass powder, but the filling failed

many times to detonate, and the explosion was unable to cause more effective expansion of

bullet than Vaseline filling, which NEVER failed to function).

This weight 2.4 grams, multiplied by the measured average velocity 322 meters per second,

products the momentum 772.8 gm/s (gram-meters per second or "gempses").

Insufficient momentum for Remington Nylon 66 or Remington Viper action,

especially when the cases were of soft brass, almost without any degree of resilience. In

the mid-1980s I knew that one kilogram-meter per second or 1000 gm/s is a momentum needed

to give a positive autoloading cycle for any & all .22 LR firearms - if the case is of

resilient material or lubricated from it's mouth to the rim. Resilience of Soviet Vostok

.22 LR steel case was somewhat insufficient, but when I found a trick to lubricate the

phosphate coated (Parkerized) shells, I was able to shoot more than 7500 rounds of Vostok

S & Hs without failures of feed, misfires or ejection troubles with my own Remington

Nylon 66.

Bullet weight was usual 40 grains or 2.59 grams and average velocity 339 mps (transsonic

or subsonic in hottest summer days). Momentum was 2.59 g x 339 m/s = 878 gm/s. Ejection

failed sometimes before discovery of case lubrication, but never more, when the shells

were lubed by rolling the cartridges between palms of hands before dropping 15 rounds into

the butt magazine of Remington and cocking the action before pushing the magazine tube

into butt all the way. (Magazine held just 14 LRs). Lube was plentily available: Vostok S

& H's bullets were as excessively greased with a messy wax - as are many Lapua .22

LRs.

I have shot Vostoks from a Finnish Army .22 rimfire training rifle, owing the barrel

length 32½ inches (SIC ! 825 millimeters) without signs of "lube run off" and

muzzle end leading. Shots were almost silent without silencer and the bullet velocity was

apparently no more than ca. 250 meters per second. I had not yet a chronograph, but some

idea about flight times of bullets, which were also possible to see in flight with a naked

eye. Another amazing finding was that Remington Nylon 66 was able to feed and eject

positively some High Velocity .22 Short cartridges, despite of it's excessive breech-bolt

weight and the momentum of a heavy linear hammer, propelled by a stiff mainspring.

Those .22 Shorts were loaded by Winchester. (One "survivor" is headstamped with

a letter "H" from word Henry). Solid bullets are copper plated. Cases are of

unplated resilient brass. Bullet weight is 2.88 grams and measured velocity (average) was

347 meters per second. Momentum was so 999.4 gm/s or not far from 1 kilogram-meter per

second minimum. Automatic ejection and feeding cycles were not "sluggish", but

rather "vehement". I noted also a "farthing" from the action, i.e.

noisy blast of powder gas from the chamber end of bore. It is easy to imagine noisiness of

that farthing when Aguila SSS is shot from 20 inch barrel of an autoloading rifle. A

mounted suppressor may made the things still more difficult.

.22 Short case is really TOO short for ALS cartridge, although I recommended it in my

suggestions to Lapua "for the preliminary test-shootings with heavy bullets, for

search of the limits of stabilizing in the varying twists of rifling", or twist up to

1 - 20". There are actually existing some (very rare) TAP Wildboar and

Finnbiathlon-22 rifles, made by Tampereen Asepaja in the late 1970s, for shooting of High

Velocity .22 LR cartridges only, with "two rotations per a meter" twist. It was

found, however, that HV .22 LR cartridges are simply not loaded for the competition

shooting, but for "plinking" and hunting only, especially for the autoloading

rifles, designed for shooting of High Velocity .22 LRs. No alteration of rifling twist can

turn the HV cartridge to become a tack-driver: It is senseless to harness a race-horse to

the mule team.

Use of a .22 Short case for loading of ALS cartridge, which must have the overall length

about similar to the common .22 LR, mainly for the feed reliability from any & all

box, drum or arched magazines without need to file, stone & hone or bend the feeding

lips. A .22 Long cartridge is not much shorter in overall length than is .22 LR but if the

positive feed reliability is needed, many magazines are needing some kind of

"adjustment". And when these alterations are done, may the feed reliability of

usual .22 LR be questionable. Summa summarum: The side profile of ALS cartridge must be

similar to that of very most reliably feeding .22 LR cartridges.

Bullet must have a round or actually ogival point; not hemispherical or blunt; not a

truncated cone or slightly rounded wadcutter. Never forget the Priority Number One:

Reliability of feed in autoloaders! Another unconditional demand is gyro-stabilization of

the bullet in 1 - 16 or even in 1 - 18 rifling twist, despite of bad ambient conditions

(frosty or rainy weather). And the bullet's flight must be TRULY (not just marginally)

subsonic despite of bad ambient conditions (cold weather, when the sonic velocity in air

is lowered) and bore & chamber conditions or barrel length. Since the early summer

1992 I have been aware of the true meaning of words "subsonic" and

"trans-sonic".

Subsonic is a bullet with muzzle velocity no more than 1000 feet per second or 300 meters

per second, shot from the velocity/pressure test barrel with a length 12 inches or 300

millimeters, the bore lapped mirror-bright and with a Target chamber (= all the dimensions

close to allowed minimum of S.A.A.M.I. specifications). All the mentioned conditions tends

to increase the muzzle velocity of 50 grains .223" diameter bullet. No actual rifle

or handgun may develope "surprisingly" high bullet velocity (say 355 mps or 12

mps more than was a sonic velocity in ambient conditions, while factory test-barrel

velocity is 315 mps with a very small plus or minus variation. Factory test-barrel length

is, of course, 26 inches...). Momentum is calculated multiplying bullet weight 3.24 grams

by velocity 300 m/s. Product is 972 gm/s - and the case friction to the chamber wall is

about 13.4 % less than the friction of .22 Long/LR case by the shorter length of ALS case

only, if the pressures and case materials are equal.

If it is simply impossible to test-shoot .22 ALS cartridges with a shorter than 26 in test

barrel, it is essential to place the limit of maximum allowed bullet velocity to 290 mps

level/ ca. 950 feet per second. Producer of Aguila SSS has seemingly adopted information

from our "Bullet Flight Noise vs. Velocity"

table, but that velocity level is impossible to reach because of too small powder volume

of .22 Short case and 60 gr bullet, along with a projectile, long enough to act as a

"compression bullet" of muzzleloader military rifles in 1850s and 1860s, and so

develope an excessive bore friction. (A lesson: Study the history, when you're evolving a

novelty ! That's the way how to evade cardinal errors).

Combination of .22 Short case and slightly more "pointed" 50 gr. bullet may be

somewhat more reasonable combination for manually loaded firearms, but the

"farthing" problem still exists in autoloaders, especially rifles, and the

powder charge shall become crammed into too small space. Just 1/10 inch more case length

may offer a drastic improvement of the situations, and the overall cartridge length shall

become just correct for LR chambers and magazines. Fifty-grainer bullet, 1/10 inch shorter

than 60 gr Aguila projectile is gyro-stable in flight, and it's point shape may be

designed to allow easier feed.

This idea was, as mentioned, sent in December 1992 to Lapua Cartridge Plant (of course

without knowledge on Aguila .22 SSS, which was at least five years later innovation,

presumably evolved indepently, without knowledge on .22 ALS concept), without any effect.

Later I suggested production of .22 ALS to Remington, and a couple of years ago to

Brazilian C.B.C. - without effect. (I was presumably thought to be some "Gyro

Gearloose" with impossible-to-realize ideas, like re-starting production of 5.75 mm Velo-Dog

revolver cartridges as the reloadible ammo for "auxiliary cartridges" or

adapters and centerfire arms with rifled barrel liners for caliber .224" ammo).

Lefaucheux cartouche, .22 short, .22 long and .22 long rifle.

Velo-Dog cartridge at right.

I am interested in the e-mail address of Russian KLIMOVSK cartridge factory! (Producer of

Vostok .22 LR cartridges ). Steel, preferably cadmium-plated steel, may be a fine case

material for .22 ALS and the bullet may also be electroplated with cadmium. It is among

the most "slippery" metallic bullet coatings, adopted sometimes in 1920s or

1930s (for the special smokeless .22 LR cartridges offered for use especially in the

autoloading firearms in USA), but later abandoned, because of poisonous qualities of

cadmium salts. Metallic cadmium is, however, considerably less poisonous than are lead or

antimony-lead alloys.

Metallic coatings are preferable on the bullets of autoloading .22 rimfire arms,

especially rifles. Thin "dry wax" coating shall run off easily, and the thick

"tacky lube" (like that on Lapua Scoremax bullets) fouls the firearms action

badly when mixed with carbon and unburned powder kernels. Feed jams of the clean firearms

are also usual, when cold weather has congealed the tacky lube. There are some old but

nowadays forgotten tricks for improvement of bullet expansion. I mentioned already a

hollowpoint bullet with a narrow but deep point cavity of Lapua's Subsonic HP bullets,

filled with mineral jelly. Depth of the cavity is 7 millimeters (.28"). I presume,

the jelly filling of point cavity may be applied in a factory without too high extra cost.

Point channel of ALS bullet may be 9 mm in depth (.35"). Bullet weight of HP

variation shall be ca. 47 grains. There is also an interesting old trick: To cut two

crosswise slashes into the bullet point. Contrary to the hollowpointing, those slashes do

not cause loss of the bullet weight. Because of the inherently slow bullet velocity and

metal plating, it is also possible to reduce content of alloying metals so that the

bullet's lead percentage is 99.5 % and the rest .5 % is antimony and traces of other

metals. Soft lead bullets needs no hollowpointing or slashing. Diameter of them may be

.223" because of the compression effect, without the notable loss of accuracy. These

options are at least worth mentioning, althought professional animal controllers

presumably prefers "handcranked" rifles and more wadcutter-like bullets.

Millions of plinkers and hunters are stuck to their beloved .22 LR autorifles and

handguns.

We must remember that .22 ALS cartridge is not intented for 60 shots prone or 3 x 40 shots

Discipline Contests with single shot bolt-action rifles. It was designed primarily for

autoloading rifles, handguns, machine guns or submachine guns, and not "For Official

Use Only" but for each & every gun-owner, for use in silenced firearms but to

become also relatively "silent without a silencer". It is designed to become

loaded with smokeless powder; the first one of it's kind since 1903 or 1914, being

designed for autoloaders and the very first one to give a TRULY subsonic bullet velocity

along with function of autoloaders.

There are many reasons, why the cartridge manufacturers are hesitant to adopt my idea,

plus one insuperable cause of negation: "N.I.H. syndrome". Abbreviation

comes from words: "Not Invented Here".

13012000; P.T.Kekkonen, Special Editor

of "GUNWRITERS ON THE WEB" on-line magazine. Joensuu; FINLAND.

P.S. Idea about re-adoptment of .30 Long Rimfire cartridge might be my.

I'll cancel it after more careful consideration: As far as possible, all cartridges must

be reloadible with use of components generally available everywhere. Good calibers for

.30/ .308/ 7.62 mm subsonic firearms are .30 M1 Carbine, .32 S & W Long or H & R

Magnum and even .32 ACP. Chambers of some firearms may be "freebored" for use of

extra-long bullets. Several years ago I had a "cane gun", chambered for a .32

ACPEL cartridge, with a common .32 ACP case but freebored throat or leade of chamber. Into

the case mouth was possible to seat a cast bullet LEE C309-180R. That's why the cartridge

was "Extra Long". I shot just some usual .32 ACP factory-loads from that

inconvenient piece of equipment, before I sold it away.

Pete

Whisper of

The Reaper

HI, I'm enthusiast about your friend's (Marko) Mosin-Nagant/ DeLisle carbine. I want to

realized it with my Lee-Enfield .303 or with my Mosin-Nagant. I want to know the number of

the holes in the barrel, their measures, the lenght of the silencers and of the barrel,

and the project of the silencers.

Thanks ; Stefano (from Italy).

"EJA, ejá, ala lá !" (Quotation is from a recording of an old Italian

song with a refrain: "Giovinezza, giovinezza/ Prima vera di bellezza..!"

and it's text starts by words: "Salve, popolo..." Can you get to me wording of

this song ? It was once upon a time like National Anthem of Italy, of course along with

the official "Mameli's Song").

I think, that LEE-ENFIELD is more authentic "basis" for the DeLisle

Carbine clone than Mosin-Nagant. Original DL Carbine was overly complicated, "ad

absurdum", because of the huge size of it's silencer unit and inherently subsonic .45

A.C.P. cartridge. Efficient it's silencer was, nobody can deny, but you may build

considerably less complicated silencing unit and use the Lee-Enfield action unaltered: Old

cartridge designs, like .303 British, are easy to handload with small charges of easily

igniting pistol or shotgun powder for subsonic velocity level.

Powder gas-bleed vents through the barrel wall are unnecessary. These are good news, since

drilling and reaming of these vents is not so easy task: Many barrels are ruined by

venting. Accuracy is many times lost permanently. Barrel length has less importance. May

be 250 to 300 millimeters, or one complete rotation of bullet in the rifling ("twist

length" of grooves plus length of the chamber, measured from the muzzle to the

frontal recess of breech-bolt head). Silencer unit itself may be ca. 50 mm in outer

diameter, of mild steel. Seamless "drawn" tubing is preferable. About tenfold

diameter ( ½ meter) is sufficient length of the silencer jacket. Baffle construction may

be similar to that of Finnish BR-Tuote suppressors with

8 to 12 semi-toroidical baffles.

I found this text from my computer 1½ months afterwards. Sorry about long delay. I

receive e-mail by our "telegraph operator" on the diskettes, since there is not

e-mail or Internet communication to my ancient computer, used just as a typewriter only.

Unfortunately I am unable to produce Auto-CAD or other easily made drawings with my

available "machinery"...

1701MM; Pete

7.62 mm M-43 / AR-15: For Subsons Only

greetings from the great state of texas. i could use any help on loading 7.62x39 subsonic

for use in an AR-15. i have a 1 in 10 twist .311 barrel. it would be nice if i could get

this load to cycle the guns as a "Normal" load would. i can lighten the bolt,

remove weights from the recoil plunger in the stock or whatever is needed. do you know if

it would be advisable to move the gas port near the chamber where gas pressure is highest?

i can use the short gas tube which is only about 3 inches in front of the actual throat

area of the chamber. would this help to cycle the action more effectively?

can i do this with standard jacketed bullets to alleviate fouling of the gas port? can i

do this without stuffing the cartride case with a filler? should i shorten the barrel to

reduce velocity? i can go legally down to 16 inches (measured from the bolt face) or i can

register the gun as a short barrel rifle if needed ($200 tax and 4 month wait) as you can

tell i am starting from scratch on this! if it were a bolt action gun this would be easier

but then again the fun is in the challenge.

Hello; Bob

Shortened gas

tube may help. Gas pressure close to the chamber is rather high, when the subsonic

cartridges are loaded with advisable "subson" powder, with the burning rate

something between HODGDON CLAYS (original Australian product) and ALLIANT (HERCULES)

UNIQUE; including both mentioned brands. I don't know, however, whether 3 inches tube

length is short enough. Gas port of US M1 Carbine is closer to the chamber mouth: Carbine

action shall give reliable autoloading with these "hot" powder, but the subsonic

velocity may be impossible to get, because the bullet of .30 Carbine cartridge cannot be

much more heavy than standard 110 grains RN. Rifling twist of a carbine is simply too slow

to gyro-stabilize longer bullets.

7.62 x 39 mm Yelisarov & Syemin M-43 cartridges you can load with extra-heavy jacketed

bullets, with a weight 170 to 180 grains. Loads you must develope without known data, but

your starting loads may be very light (2 to 3 grains of handgun or shotgun powder; depents

on the burning rate). For .311" bore are .311" diameter bullets recommended;

those made for .303 British/ 7.65 mm Argentine Mauser or 7.7 mm Japanese rifle. Roundnose

plain based bullets are good for subsonic loads of M-43 Russian cartridge. Boat-tail

hollowpoints may be too long to become gyro-stable in 1 - 10" rifling. Original

Kalashnikov barrel has 240 millimeters twist.

Lightened bolt may help the autoloading, but if you are made a light bolt and reduced

recoil plunger and moved the gas port backwards, you must forget shooting the

"Normal" factory loads or handloads with usual rifle powders, giving the muzzle

velocities of full-powered ammo. Your rifle shall become "for subsonics only"

piece of equipment ! IMPORTANT NOTICE: Shortened barrel shall not reduce the available

velocity of subsonic handload bullets. On the contrary: Bullet velocity may be higher when

shot from 16" barrel than the velocity available from the standard barrel. Bore

friction of a jacketed bullet slows down it's velocity after acceleration gained by 10 to

12 inch travel in the rifling.

One of my friends in Finland has made a really unique rifle from the .308 Winchester

F.A.L. Autorifle for shooting of very mild subsonic handloads: He removed by grinding a

locking lug of a spare breech-bolt. His F.A.L. is a blowback rifle (with the gas piston

actuation), when the modified bolt is in the action, and when he shoots full-powered

factory loads or handloads, he can use an unaltered breech-bolt. Power of his subson

handloads is about similar to that of .32 ACP (pocket pistol) factory loads; almost silent

without silencer, save the noise of autoloading cycle.

I don't know mechanism of AR-15 well enough to say, whether it is possible to grind away

the locking lugs of spare breechblock of it, and use it as a blowback action rifle. If it

is possible, the cartridges must be handloaded to the very low power level, with a

standard bullet weight (123 grains) and start from (say) 2 grains of fast-burning powder

like Hodgdon CLAYS or VihtaVuori N 310, and step up the charge with .1 grain increments

until the bullet velocities are uniform. AR-15 with a blowback bolt needs not a gas tube

at all. Without a gas actuation it is possible to load the cartridges with somewhat

heavier powder charges, because the gas cannot kick the bolt open too rapidly.

Some earliest pre-Kalashnikov AK 47 prototype firearms were designed to function like

common submachine guns, even with the full-powered 7.62 mm M-43 cartridges, but they were

found to be impractical, because of a rather high chamber pressure and needed heavy weight

of the breech-bolt. With the reduced charge handloads may a blowback action be functional.

It is unnecessary to use any case filler material in 7.62 mm M-43 cartridges, but an

useful trick is to drill the flash hole (vent) of primer pocket with (up to) 4.0 mm/

0.16" drill bit. Too small flash holes of Boxer primer pockets were designed in 1868

for ignition of contemporary military rifle cartridges, crammed full of black gunpowder. A

small charge of smokeless powder needs more sudden and wide ignition flame from the

primer. Also is beneficial to lube the bullet of subsonic cartridge. Thin coating of

Molybdene Bi-sulphide on the jacketed bullet is useful lubrication, but almost any fatty

substance shall reduce the bore friction and variables of bullet velocities.

A lubricated cast bullet (.312" dia.) with a gas check is usually ideal for subson

loads, but cast bullets designed for 7.62 M-43s are inherently light, short and

sharp-pointed. A short-necked cartridge case and strictly limited overall cartridge length

are negations to successful use of cast bullets with a weight more than 150 grains.

1601MM; Pete

Still another wildcat caliber ?

I have been trying to think of a cartridge that will fit in .308 Win class bolt action

rifle, for suppressed subsonic use only. It must be roughly the same size as the .308 Win,

as I want it to feed well. Had thought of .308 Win with a fast 1-8" twist or .338

Whisper (7 mm Remington Brenchrest, necked up to .338). But what would a standard .308 Win

case be if necked up to .338 size ? The idea is to get the heaviest bullet weight I can

with jacketed rifle bullets. The rifle would have a barrel of around 12" and a large

silencer. A twist would be 1-10.

The question: Would the smaller .338 Whisper be better than the .338/308

wildcat ? The longer .308 case could offer more protection for the heavy bullet while

in the magazine.? The 1-10" twist would stabilize Lapua 250 gr and Sierra 300 gr,

.338 bullets, hopefully, or would I need a faster twist ? Any thoughts will be much

appreciated.

Yours Faithfully, Chris

Hi again,

Chris! I am sorry about the more and more long delay between the questions and my answers.

Many Finnish visitors are asking questions too. Those, who have paid the (rather nominal)

annual fee for keeping "Gunwriters On the Web" sites alive at all, are

privileged to get answers. Millennium is over. Now is 00:45 o'clock in 1st January '00 and

my old computer works very well. Stories about the Grand Total Delete of memory

seems to be just fairy tales. I'll look, however, whether my "ARCANE"

stories are still existing. (It is)..!

I presume, there are many "wildcatters" already designed a necked-up .308 Win

cartridge for .338 caliber bullets. I recommend also fire-forming of the case to make it

slightly "improved" one, with shoulder angle 25 degrees. There is an existing

factory-designed/factory-loaded cartridge .358 Winchester available since 1955, with a

shoulder angle mere 20 degrees. It became never very popular, because of some

"headspace troubles": If the cartridge was pushed speedily into the rifle

chamber, it could enter too deeply forwards, causing even misfires and extraction

failures. Especially some lever-action rifles suffered from these headspace problems. At

least SAVAGE Model 99 and BROWNING BLR rifles were (are ?) chambered for .358 Winchester

cartridge.

A much older .35 Remington cartridge, shooting the very same .358" diameter bullets,

designed in 1906 for a selfloader and slide-action rifle, didn't cause troubles, although

it has a case shoulder diameter .425" (10.80 mm) while that of .358 Win is .454"

(11.53 mm). Shoulder angle of .35 Rem case was carefully calculated 23 degr. 25 minutes.

With 25 degr. angle it is possible to use even the European 9.3 mm bullet in a necked-up

"improved" 9.3 x 51 mm wildcat cartridge with .308 Win fireformed case. For the

silenced rifle has 9.3 mm caliber, however, no advantage over .358" projectiles.

There is huge selection of factory-made lead bullets available for .358 caliber rifle, but

no more for 9.3 mm guns. And "happiness is a lubricated lead alloy bullet" for

the user of silenced rifle..!!

Your idea of necked-up 7 mm BR Remington case with .338" bullet sounds to be

reasonable - but - why to content yourself with half measures ? The universal scourge of

modern bottle-necked rifle cartridges is too short case neck - especially for use with the

swaged or cast lead alloy bullets. You may design a wildcat cartridge with a case body

length like that of 7 mm BR Rem and 25 degrees shoulder, but sized from a full-length .308

Win case for seating of .338" bullet. You must get a custom-made kit of sizing and

bullet seating dies, along with 3rd die for expansion of a case mouth (and flaring of it

for cast bullet seating).

It is possible to ream the rifle chamber with a sizing die reamer and to grind or

"lap" it slightly more large with sized cartridge cases and valve grinding

paste. Because your rifle shall be unique (one of it's kind), just a little allowance is

needed between the dimensions of cartridge case and rifle chamber. It may be made along

with "NIEDNER's Principle", so that you should not resize the cases after the

shooting at all, but just to reprime them, charge them with powder and seat the bullets.

When seating cast lead bullets, the case mouth must be slightly flared. If the bullets are

"gas checked" (which is recommended) it is needed just to bevel the inner edge

of case mouth. If flared, the case mouths must be also crimped enough to make them again

cylindrical or very slightly tapered. Bullet diameters must be as uniform as possible, and

so also the thicknesses of case neck walls. If a jacketed bullet is too "fat",

it is advisable to lathe-turn it to the correct diameter, and not try to squeeze it

through a bullet sizing die. Lead alloy bullets are easy to size with it. Slightly

undersized bullets are easy to "paste in" to the case necks with a sticky bullet

lubricant or even with the beeswax or candle wax, while applying a dip-lubrication; which

is a beneficial procedure - even for the jacketed bullets of subsonic handloads.

In the Good Old Times - presumably before invention of A.O. Niedner's

Principle of precision fit between cartridge "shell" and a rifle chamber -

dipped many Finnish target rifle shooters their loaded cartridges into the melted bovine

or mutton tallow entirely, hanging them bullet end downwards by the case rims. (Caliber of

the Target or Schützen Rifle - a "tussari" in arcaic Finnish - was

usually 8.15 x 46R, but .32-20 Win rifles were also used). The tallow coating prevented

expansion of a cartridge case. Resizing of the cases before reloading of cartridges was

unnecessary, but the tallow was obliged to wash away after the shooting session, because

it stained the brass "ugly" (= green in color). It didn't made the brass more

brittle.

Some shooters had tin-plated or even nickel-plated cases for use with tallow coating. They

were not lathe-turned solid-wall "Everlasting cases", but they could stand

several thousands reloadings and shots before the primer pocket became too large to hold

the primer - not because of chamber pressure (which was very low), but by the abrasion of

priming mass residue or careless use of depriming chisel. Most 8.15 x 46R cases had BERDAN

primer pockets with an integral anvil, very easy to ruin with a sharp chisel point. Those

.32-20 Winchester cases with BOXER primers were less risky to de-prime and re-prime.

The cases were sometimes neck-resized, if the neck was expanded too large to hold the

bullet and enter the chamber easily, but this action was carried out on a mature

deliberation. Riflemen knew since 1880s until early 1930s that ANY - even the slightest -

sizing of the cartridge case shall reduce it's active life. So it was essential to

eliminate the permanent case expansion and avoid need of any resizing.

Summa summarum: This combination of .308 Win basic case and .338" bullet sounds to be

functional, but somebody must be able to design and make a custom-made reamer for sizing

die of cases, especially if they are long-necked shells (.338 x 2"), and also a

reamer for the case neck inside diameter. If the neck wall is too thick, there is a risk

of explosion of rifle because of an excessive bullet friction in the case neck.

07012000; Pete

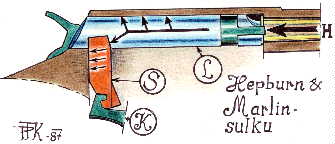

AL-43 Assault Rifle & mid-sized cartridges

Mr. Kekkonen: I read mention yesterday evening of Aimo Lahti's 1943 assault rifle in Suomi

History 2/2. I've been wondering for 35 years if this the "delayed blowback"

Suomi variant mentioned in Hogg's Small Arms Of The World which fired a 7.62 mid-sized

rimmed round (a shortened 7.62 mm Mosin-Nagant rifle round similar to the 7.92 x 33K and

its parent 7.92 x 57 ?). Your reply to both the weapon and the cartridge are appreciated.

Respectfully Yours; John

I have

held one AL-43 assault rifle prototype in my hands several times in the 1980s, when it was

in possession of Factory Studying Collection of VALMET TOURULA WORKS, but that collection

fell suddenly to the hands of enemy (SAKO Oy) about twelve years ago. I have no literature

about AL-43 at hand but just some "as-far-as-I-can-remember"-knowledge: Just

some prototype rifles were made by a Finnish firm PARTATERA Oy (Razor Blade Ltd.) as a

"Raskas Konepistooli m/43" (heavy submachine gun Model 1943). I had never enough

time to disassemble that rifle, but I think, it's action is a copy of Italian FIAT machine

gun / OFFICINE VILLAR PEROSA Model 1915 "miniature machine gun" / BERETTA Model

1918 submachine gun.

(All of them had similar delayed blowback action with a rotating breech-bolt but a

top-mounted vertical box magazine. AL-43 rifle had a bottom-mounted drum magazine for 56

rounds). The "heavy submachine gun" looks like a over-grown SUOMI KP/31. Weight

is ca. 6 kilograms with an empty magazine. According to the most respected Finnish

authority on firearms, Master of Arts MATTI U.K. VIRTANEN, the AL-43 prototypes were not

suitable for mass-production or use in the real battle, but they were just some kind of

cartridge test-shooting and comparison devices. Of course, they were never

"discharged in anger".

Finnish military authorities became aware of German assault rifle and cartridge designs in

the late 1942 or very early 1943. Some Finnish officers, who were ex-services of Imperial

Russian army, were also red the books and articles written by V.G.FYODOROV, who was able

to predict the arrival of 1st generation assault rifles, intermediate-length cartridges

and (NOTA BENE !) also the 2nd generation cartridges, like 5.56 x 45 mm NATO and Soviet

5.45 x 40 mm M-74 ... in the late 1920s.! This same Fyodorov was designed the first 6.5 x

50 mm "ABTOMAT" (assault rifle) in 1916.

It is not known, who designed Finnish war-time assault rifle cartridges, because all the

knowledge on their history is kept by the historians, who are not interested in the

cartridges, but they are also hostiles to persons, who are able to compile needed

information about history of military cartridges and cartridge designs in Finland. A book

"SUURI PATRUUNAKIRJA" ("The Great Cartridge Book", by TIMO HYYTINEN

& al.) was planned to become published ten years ago, but the plan was abortive. I

don't know, why..!! I have collected my scanty knowledge on 7.62 mm MOSIN cartridges by

correspondence, mainly from Germany, and from some French sources.

No information is offered to me from Finland, ESPECIALLY about Finnish military cartridges

and factory loads, with one exception: Home archives of M.A. Matti U.K. Virtanen (about

Civil Guards cartridge orders from SAKO Oy and cartridge designs) has been valuable source

of knowledge. Mr. Virtanen collected historical documents for the book "Suuri

Patruunakirja". He was also a co-editor of that planned book, which was never allowed

to become published. Finnish Ministry of Education was one known participant of "the

censorship plot".!

There were three kinds of heavy submachine gun cartridges designed in Finland, without

known immediate patterns. They are all loaded into RIMLESS cases. I have seen all of them.

Two of them were developed for 9 mm and 7.62 mm versions of AL-43 and third one for very

rare LILJA Carbine (which is usually mis-classified as a "submachine gun").

Cartridges for AL-43 were presumably based on the 6.5 x 55 mm Swedish MAUSER cases, with a

slightly bigger case head diameter than that of German Mauser cartridge Model 1888 (and

all of it's clones, like .30-06, .308 Win and their untold necked-up or necked-down

variations). Cases were made by LAPUA plant of VPT (Valtion Patruunatehtaat/ State's

Cartridge Manufactures, which had the plants also in Kanavuori and Ahtari, not in Lapua

only, during the 3rd Finnish Independence War in 1941 - 44).

Production of 6.5 x 55 mm cartridges was started after the 2nd Independence War, a.k.a.

the Winter War 1939 - 40. Since the order of Swedish Government, in August 1940, until the

end of year 1940, there were produced 18.5 millions rounds of 6.5 mm cartridges by Lapua

plant for Sweden, and when the production of them was ceased in 21st June 1941 (one day

before start of "Operation Barbarossa"), the grand total production of 6.5 x 55

mm Swedish cartridges was reached 65.9 millions rounds, lacking just 100 000 rds from the

Swedish order - but since 22th June, 7:15 o'clock there was a helluva hurry to start again

production of 7.62 Mosin-Nagant cartridges for our own armed forces "with a High Gear

switched on". There were, of course, a lot of surplus 6.5 mm cases left for prototype

cartridge designing.

Dies and tools for production of 6.5 x 55 mm cartridges were also still existing in 1943,

and there was a "lull time" of production, due to the lack of materials in VPT

Lapua plant, and a good time for evolution of some promising products - like the short

cases for AL-43 heavy submachine guns. I presume that the cartridge manufacturer was more

enthusiastic over the intermediate-sized cartridge than Aimo J. Lahti was about designing

of his assault rifle. Lahti was aware of the very limited resources of Finnish firearms

industry during the last half of our 3rd Independence War: Finland should be the least

possible country to adopt an entirely new kind of military firearms.

The minor improvements of KP/-31 were rejected in 1942, including the front sight

protection "ears" and the butt-stock mounting with a "MARTINI-HENRY"

bolt. There was not the production capacity even for the prototype samples of AL-43 by VKT

or TIKKAKOSKI Oy, but just in the small shop, which made GILLETTE razor blades and steel

washers for the barrel flanges of SUOMI KP/31s and toggle-joint adjustment washers of

MAXIM machine guns. In Finland there was not capacity for the complicated sheet steel

stampings, needed for mass-production of assault rifles similar to German MKb 42/43

(a.k.a. Sturmgewehr 44). AL-43 prototypes were therefore designed for production with

usual toolmaking shop's machinery, by highly skilled craftsmen; not for mass-production.

As mentioned, there were both 9 mm and 7.62 mm variations of the heavy submachine gun

AL-43. The cartridges had case length 35 mm; so the caliber designations were 9 x 35 mm

and 7.62 x 35 mm. The first one looks like .357 Auto Mag wildcat cartridge with a

roundnose FMJ bullet, but the case is longer by two millimeters. 7.62 x 35 mm AL-43

cartridge looks like .308 x 1½" BARNES wildcat with a pointed FMJ bullet, but the

case is ca. 3 millimeters shorter. 9 x 35 mm AL had somewhat better "stopping

power" at short ranges than 7.62 mm variation and slightly higher muzzle velocity,

but it's standard bullet (weight 7.5 grams/ 115.7 grains ?) had a rather poor sectional

density, ballistic coefficient and penetration, when compared with 7.62 mm projectile. 9

mm variation was abandoned after comparisons; presumably before the end of year 1943.

7.62 x 35 mm AL cartridge had a performance about equal with Soviet 7.62 x 39 mm M-43

(actually German 7.75 x 39.5 mm GeCo Model 34/35 cartridge). Finnish 7.62 mm cartridge

might give somewhat slower muzzle velocity, if it had then-standard S-30 flat-based

pointed bullet, weight 9.6 grams (148 grains). Ballistics of these cartridges is mere

guesswork. I cannot get confirmed information about Finnish cartridges from any Finnish

source (with an exception of M.A. Matti Virtanen), and about these rarities I am unable to

get data even from the colleagues living abroad. Sorry !

Cartridge of Lilja Carbine was based on 9 x 19 mm (Luger/Parabellum/submachine gun) case

extented to 40 millimeters length and equipped with usual 9 mm round-nose FMJ bullet. This

carbine has a plain blowback action with a hammer or striker mechanism, just like that of

selfloading 9 mm or .45 ACP "pistol carbines", popular in USA before restriction

of their sales. Lilja Carbine has, however, a movable barrel, like that of firearms with

short recoil action (pistols and machine guns since MAXIM MG). The barrel is not connected

with a breech-bolt by any mechanical means, but just by the friction of extra-long case

after shot, when the chamber pressure is still high.

Reciprocating barrel follows the breech-bolt, until the pressure in the bore and chamber

has dropped to safe level and the case wall is loosened from chamber wall by the

elasticity of case brass. Now the barrel return spring starts to push the barrel into it's

foremost position, while the extractor hook of breech-bolt pulls the spent case from a

chamber. Bolt completes ejection of the case and feeds the fresh cartridge into chamber

after re-cocking of the firing mechanism. Similar functioning is applied later in USA to

some handguns, namely ill-fated pistols designed by JOHN W. KIMBALL, Detroit, Michigan

(calibers .30 MI Carbine and .22 Hornet), introduced in 1955, discontinued in 1958, and

COLT COLD CUP NATIONAL MATCH pistol (caliber presumably .38 Special, flush wadcutter

target load only).

History of last mentioned pistol is unknown to me, but existing of barrel return spring on

the exploded drawing led (or misled) me to the conclusion that the barrel is reciprocating

one. Distance of axial barrel movement cannot be more than a couple of millimeters. Barrel

of Kimball pistols went backwards along with the slide 5 to 7.6 millimeters and barrel of

Lilja Carbine retreated at least 15 mm. (I have seen the prototype carbine in Tourula

Works Studying Collection in 1988. Presumably it is a really unique object. The collection

is nowadays scattered: Some objects are accommodated to Finnish Hunting Museum in

Riihimaki. Fate of the military firearms is unknown to me. A vast majority of objects were

military arms, including anti-tank rifles and 20 mm machine cannons).

Ballistics of 9 x 40 mm Lilja Carbine cartridge is, of course, unknown. It looks like .357

Maximum/Super Magnum cartridge without rim, with an extractor groove similar to that of 9

mm Luger case, and is equipped with usual 9 mm FMJ RN bullet. Head diameter is usual 10

millimeters and case mouth diameter 9.6 mm. Straightened case of 5.45 x 40 mm Russian M-74

cartridge is similar to 9 x 40 mm Lilja case, but the original Lilja shell is of brass.

VPT was bought some machinery for production of the steel cases and bullet jackets from

Germany, but the war ended before start of "iron age" in VPT. Production lines

of steel cases and jackets were incomplete and the personnel of Lapua was lacking some

know-how on "substitute cartridge" production.

Muzzle velocity of 115 grains bullet may be ca. 2000 feet per second or somewhat higher.

Inspector ERKKI LILJA of VKT (later: VALMET Tourula Works) started design of his

carbine during the war, presumably in 1943, but because there was not production capacity

for new-fangled firearms in VKT, he completed his prototype not until early or

mid-fifties. Barrel jacket of carbine is "Parkerized" or phosphate-coated. This

coating was adopted not until 1950s in Finland. 9 x 40 mm cartridges were loaded by VPT

during the war, like cartridges for AL-43 prototypes. Last test-shots from 7.62 mm AL-43

were shot in 1945.

As mentioned, I have no technical data of AL-43 easily available. Lilja Carbine

has characteristics as follows:

Caliber: 9.00 x 40 mm (lengthened, almost parallel-sided case).

Barrel length: 415 mm/ 16.3 inches.

Overall length of carbine: 925 mm/ 36.4".

Weight with empty magazine: 4 kilograms/ 8.83 lbs.

Magazine: 20 rounds; staggered box.

06012000; P. T. Kekkonen

Silence WithOut Silencer

Dear Sir, I greatly enjoy your site. I have a question for you I have read your comments

on the long barrel .22 rimfires, and have been looking to buy the longest barreled pistol

caliber (.38 - .45 or so) rifle that I can find. I think I have found exactly what I have

been looking for. There are several variations of lever action rifle replicas with 24 inch

barrels and Cimarron (I believe a US Importer) brought in 30 inch replicas of the Model

1873 Winchester lever action chambered in .22 LR, .22 WMR, .357 Mag, as well as .45

Long Colt. If I cannot find the 30" Cimarron, Marlin makes a 24" Cowboy

Classic in the same calibers that I might try as well. Soon I'll have a LONG barreled

rifle for .45 Colt, so what ?

Well, in the Handloaders Digest (15th ed. 1996 page 186) there is an article on "The

Quiet Big Game load" by P. A. Widegren (I can fax you the article if

you cannot get it otherwise). In it he describes a 500 grain lead Wadcutter load he

developed for the 454 Casull Revolver that he achieved 950 feet per second with 15 grains

of Winchester 296 powder (16.5 grains was all he could stuff in to the case without

deforming the bullet nose) through a Magna Ported 6 inch 454 Revolver.

Because of the minimal length of the flatnose bullet, I think it could be stabilized by

the lever action's rifling. (If this really works, I would then look at a radical boattail

- teardrop design - even if I needed a fast twist barrel) PS: Can you show the various

BC's for subsonic bullets.? Is the sharp pointed bullet turned backwards (tail first)

really the slipperiest bullet in the subsonic region ?

But before I go off and chuck a pile of money into this venture I would like to solicit

your advice & input. A TRULY QUIET rifle shooting 500 grain bullets at 800 - 900 fps

would be just the ticket for shooting without hearing protection, etc....

Rusty

Comments & I have just some experience about handloading of very mild S.W.O.S.

loads for .357 Magnum BROWNING lever action rifle (a very cute modified Japanese copy of

WINCHESTER Model 1892) by the commission of Finnish Police Arms Depot. Our Men in Blue had

in the early 1980s .38 Special SMITH & WESSON revolvers coming to be the standard belt

handguns. Previously they had .32 A.C.P. caliber F.N./BROWNING Model 1910 - if not Model

1900 - pistols, usually carried in their back-pockets, and many times left home. (A need

for actual use of the handgun is still extremely rare in Finland. Many policemen, nearing

the retirement, have "never discharged a shot in anger").

Chief of the Police Arms Depot knew very well that the use of firearms was usually to put

down the animals (cats and dogs, but occasionally whitetail deers, cows, horses and even

the big - up to 1000 lbs on the hoofs - mooses), injured by the traffic accidents. A

snubnose revolver was sometimes too noisy for this purpose, and it is much more difficult

to shoot a lethal shot with any handgun than with any shoulder arm, even to the very short

shooting distances. It was also a good idea to adopt the very same or similar cartridge

for handguns and shoulder arms. Carbines were not intented to become personal weapons but

to be the armament of patrol/cruiser cars and "Black Mary" vans.

It was possible to chamber the lever action Browning carbine with .38 Special police

revolver cartrige (with 158 grains lead bullet, of somewhat harder alloy than usual LAPUA

bullets) and a Silent Without Silencer cartridge for animal control or "coup

de grâce" commissions in the densely populated areas, or the full-power .357

Magnum cartridges, fed from the magazine for the most nasty operations of law-enforcement.

In those days was a SUOMI KP/31 an official police's long gun for emergencies. It was not

carried in a police car or van as routine, and it is hard to think use of KP/31 as a

"first line counter-sniping weapon", because it had just the iron sights, and

many policemen never learned to master it. Also there was not a silencer or Silencer Barrel Unit designed for KP/31 in early 1980s.

That Coup de Grâce cartridge of my design was loaded into the .357 Magnum case with usual

LAPUA 148 gr lead wadcutter bullet, seated into the case to much more depth than wc bullet

of usual target revolver load. Powder charge was mere 3.5 grains of VihtaVuori N 14

(salvaged from 7.62 x 39 mm blank cartridges), but the reduced powder volume assured it's

regular ignition. The lubrication of lead wadcutter bullet was, and it is still,

insufficient. So I filled the empty mouth of case with melted wax (beeswax with some

paraffine wax added), used for coating of Finnish Edamer cheese. Case mouths were crimped

no more than was needed to remove their mouth flare (which is essential for seating of

frail hollow-base wadcutter bullets).

That wax sealed the bullet hermetically and it was also a kind of code color, being bright

red, but it's purpose was primarily to prevent the bore leading. I was shot no more than

20 or 25 rounds of these cartridges, when The Reaper cancelled the commission of load

development: Chief of Finnish Police Arms Depot passed away suddenly. Owner of that test

carbine called his sample-gun back, also very suddenly, without any explanation.!

It was an era of "Governmental Hoplophobia" in Finland. Ministers of

the Interior were not human beings at all: They were, as a rule, the leftist radicals -

the creatures like a cattle or beasts of burden. And the officials of that Ministry,

especially those of the Police Administration, were hoplophobics; some of them inherently

and the others "ex officio". In those circumstances it was impossible

to adopt "the Wild-Western Gun" as a police carbine, despite of it's

versatility.

I could just test the noise level of my special load. It was like snap of a dry broken-off

pinewood branch, thickness about one inch. I had no means to measure the noise level. I

had a chronograph, but not yet an opportunity to measure bullet velocities, or carry out

penetration tests or accuracy test-shootings. I know, however, that the lever action rifle

and a handgun cartridge (especially the hand-loaded one) is not overly noisy combination,

even without a mounted silencer. Finnish police adopted later 9 mm CLOCK pistols

and HECKLER & KOCH MP 5 submachine guns; some of them equipped with silencers. The old idea of late NIILO UUSKALLIO became realized

(= same caliber of handguns and light shoulder arms), but versatility of a lever action

carbine is impossible to achieve.

A submachine gun with delayed blowback action is inherently noisy, because of mechanical

noise of the action - even when shot with a silencer and subsonic cartridges. And that 9

mm Luger cartridge is, on the other hand, impossible to become loaded to the performance

of .357 Magnum. You must remember that a .357 Magnum cartridge, when handloaded especially

for shoulder arms, with a proper powder and premium bullet, is a lot better deerslayer

than is .44 Magnum, when loaded for a handgun with too light or frail bullet.

But now to your .45 Long Colt lever action rifle with TRULY LONG barrel: Your idea is O.K.

If you must get your rifle re-barreled, my recommendation is to get a barrel-blank rifled