<< Newest Q&A

More Q&A, Part 17 >> 16

>> 15 >> 14 >> 13 >> 12 >> 11 >> 10 >> 9 >>

8 >> 7 >>

6 >> 5 >> 4 >> 3 >> 2 >> 1 >> Gunwriters guns.connect.fi

Link page

Custom Search

Latest update 08.03.2002

G.O.W. Kickback:

Questions and Answers, Part 18.

Answering readers' questions is discontinued because of death of the editor of this column, the famous gunwriter P. T. Kekkonen.

TEXAS RANGER REVOLVER

I am wondering if you could give me some information on a pistol? It is an older .38

caliber and the marking on the barrel is: TEXAS RANGER FOR 38 S & W SPECIAL CTGES. On

the underside of the barrel it is stamped BELGIUM. The other side of the frame is stamped

38 W. The pistol is both single and double action. I know that Smith & Wesson 38

Special cartridges were not developed until 1899. I have attached two pictures of the

pistol. Any information would be helpful.

John, CA.

.38 S & W Special cartridge was

introduced in 1902. TEXAS RANGER revolver was a Belgian copy of Spanish EIBAR Model 1929

revolver, made sometimes in 1930s. Nobody know manufacturer(s) of these Belgian

"pirate copies". Engraving or stamping of the factory brand on the firearms was

not mandatory in Belgium, and therefore just the makers of high-quality arms (like AUG.

FRANCOTTE, F.N., PIEPER/BAYARD, A. SIMONIS, CENTAURE and some others) were proud enough to

tell: "We've done this gun!" There were presumably hundreds of small workshops,

especially around the township of Liége, producing cheap handguns and shotguns, usually

unlicenced cheap copies from the firearms of better quality, or just the parts of these

unmarked guns.

"Western style" revolver TEXAS RANGER, caliber .38

Special. Made by unknown Belgian manufacturer(s). A copy of Spanish EIBAR Model 1929

revolver. Standard model with wooden grip panels. Some more expensive variations had bone

or even ivory grip panels.

EIBAR M 1929 revolver was a pattern of Texas Ranger; copy of COLT

Model 1872 with somewhat improved single & double action trigger mechanism. Grip

panels are of Ebonite/Vulcanite (hard rubber).

Source of drawings: ASE-ATLAS by A.B.ZHUK

(Russia/Finland).

If the product was strong enough to survive proof-shooting in the proof-house of Liége,

it was allowed to sell and export all'round the world. Proof-shooting was mandatory, but

the LEG stamp in oval with a crown on it and a star was not a warranty that the firearms

were able to stand extended use. Please, do not shoot from your revolver .38 S & W

Special cartridges other than very mild target loads with wadcutter bullets and low

pressure! It is always better to be safe than sorry.

1402 MMII; PT

WOUNDING EFFECT AND KILLING CRITERION

Great respect for your very good internetsite and your knowledge. After reading the

various Q & A, I also had a question. I'm very interested in ballistic and wound

effect comparison between the old smoothbore-muskets and first rifled-muskets and the

modern rifles beginning on the end of 19th century. So can you give an answer for

effective wounding range for the guns below:

1. Smoothbore pistol, say about 1780-1830?

2. Smoothbore musket about 1780-1830?

3. Rifled musket about 1780-1830?

When you compare the musket balls and Minié-bullets with point-nose bullets of WW1 what

do you mean had the greater wound effect? I hope I take not to many from your rare time

for answer my question.

Many thanks; Harry

On our GOW

Finnish site exists sometimes word "tappokriteeri". It means

"killing criterion", ability of projectile to cause a lethal wound when a

dressed adult human being is hit with a projectile (usually on the torso of body). Old

rule of thumb is: "A bullet or fragment of a bomb or artillery shell is able to kill

if it is able to perforate a pine board, thickness 25 millimeters/ one Imperial

inch". This criterion is still valid, because human beings have still similar

construction than they had about 150 years ago. Some most powerful air rifles are able to

perforate 25 mm thick dry soft pine or fir board. Bullets or pellets of them are also able

to kill an adult human being by a hit into the torso or (especially) by the head shot.

Caliber of the projectile may be as small as 4.5 millimeters, but a small pellet should

penetrate some vital organ like heart or large blood vessel, brain or some delicate organ

in the abdominal cavity. Before the era of antibiotics, all hits through the bowels could

be lethal by peritonitis. Therefore the Deringer pistols and .22 Short caliber Smith &

Wesson revolvers Model 1857 were adequate weapons for self-defence. Bullet of the First

Model S & W revolver (propelled with 4 grains of blacpowder) barely perforated one

inch thick fir board. Spherical bullet of original muzzle-loader Deringer was able to

penetrate the pine to depth of bullet's diameter at very short range: Less than half from

"killing criterion", but many shots from tiny Deringers were lethal - sooner or

later. Well-known occurrence was assassination of U.S. president Abraham Lincoln.

You are asking presumably performance of military firearms in era 1780 - 1830? I can give

just some crude estimations of their effects. During this era the Minié bullet was not

yet invented. Pistols, muskets and rifles shot still somewhat subcaliber spherical lead

projectiles. Average caliber of military pistol was ca. 17 millimeters. Caliber of musket

could be up to 20 mm. Average was about 18.5 mm (similar to cylinder-bored 12 gauge

shotgun still today). Caliber of rifles was slightly smaller, but they shot usually

bullets with diameter similar to balls of muskets, sealed to the rifled bore with a cloth

patch. Rifled muskets were smoothbore muskets rifled afterwards. Rifle-muskets were made

to shoot pointed bullets. Diameter of average pistol bullet was ca. 16.5 millimeters and

that of musket/ rifled musket ball ca. 17.9 mm.

1. Estimated lethal range of pistol bullet was up to 200 meters. Wounding effect could be

to ca. 300 meters and some kind of bruise the 16.5 mm bullet could make at range 500

meters, but the bruise was usually not incapacitating. Effective range of smoothbore

pistol was considerably less than 50 meters, because of poor accuracy.

2. Smoothbore musket had the lethal range 300 to 350 meters, wounding range to 450 - 500

meters and bruising range to ca. 700 meters, because of heavier bullet weight and higher

muzzle velocity, as much as 400 meters per second (equals velocity of modern 12 gauge

shotgun slug load). Accurate range was, however, usually less than 100 meters.

3. Bullet from the rifled musket (or earliest sniping rifles like British Baker Rifle) had

lethal/wounding/bruising effects similar to the contemporary smoothbored musket, but the

accurate range was extended up to 200 - 250 meters, and a skilled sniper was able to hit

individual enemy soldier up to 150 meters range (with some good luck) and place the hit on

some predestinated part of the body, like stomach, chest or head. With smoothbore muskets

the firing was usually not aimed but just directed towards the row of attacking enemy

soldiers. After one or two volleys the close-range combat with bayonets determined, who

were winners or loosers.

General adoptment of Minié bullets and rifled muskets extented the lethal range of rifle

shots up to ca. 500 meters and the wounding effect to 700 - 800 meters, but "trés

formidable" recoil of 17.5 - 18.5 mm rifled muskets scared average shooters to jerk

the trigger. Shooting accuracy was not improved to the wished-for level. During the

Crimean War (1853 - 56) was noted "trés formidable" (= horrible) wounding

effect of original French Minié bullets with the conical sheet iron "culot"

inside their base cavity.

Many times the "Minye Pulya" (so-called by Russians; opponents of the Britons

and Frenchmen in that war) made two or even three wound channels after their hit and

disintegration. One channel, made by the heavy solid bullet point, went through, making

perforation. Second channel was done by tubular skirt of Minié bullet and third one by

the truncated sheet iron cone, which was later found to be unnecessary for expansion of

these projectiles. Those secondary crooked wound channels were just shallow penetrations,

but they enhanced bleeding from entrance hole.

Old Model Minié bullet with sheet steel "culot" cup. Original French

bullet had more large base cavity and culot. Skirt of bullet base was very thin and

weakened by the "grease grooves". When hit, the bullet could disintegrate,

making two or three "sub-projectiles": Point, skirt and culot. Bullet could

disintegrate also in the bore of a rifled musket, leaving the skirt stuck into rifling.

Therefore it was essential to make the base cavity smaller and a skirt thicker when

caliber of rifle-muskets was reduced to ca. 15 mm and pressure of powder gasses was

increased accordingly. Caliber of old rifled muskets was ca. 18 mm. Thickness of their

barrel wall was insufficient to withstand high (more than 300 - 400 atmospheres) pressures

when weakened by rifling.

Lethality of these bullets was unrivalled, but just the most robust riflemen were daring

enough to shoot them with full charges of powder. Average soldiers shed secretly almost

half of the powder charge from their paper cartridges away before pouring the charge into

bore of the rifled muskets. Recoil was now tolerable, but the trajectory of heavy Old

Model Minié bullet was like that of a baseball. Lethality and wounding effect were

considerably reduced, but they were still sufficient at close ranges, when the soldier was

"able to see whites of the eyes of an assailant". Skirmishes were still ended by

the fight with "crossed bayonets". During and after the Crimean War the rifled

muskets were found to be a kind of makeshift ordnance.

For truly efficient use of Minié bullets was needed to reduce caliber, bullet weight and

powder charges. Bullet velocity could be increased and get flatter trajectory without

excessive recoil of rifles - or rifle-muskets, as they were called until the end of

muzzleloading era especially in U.S.A. Calibers were reduced to 14.66 - 15.44 millimeters,

but some countries were still more progressive.

British-designed Pritchett bullet was smooth-sided, with a shallow base cavity. It was

possible to produce these bullets by swaging from lead cylinders and so avoid faults of

cast bullets. Pritchett bullets were popular in the American Civil War. Caliber was .577

while American rifle-muskets were usually bored to caliber .58 (14.7 mm). Bullets were

wrapped into lubricated paper patch. Some clearance between bore and bullet was therefore

needed for muzzle-loading. Not only the hollow base but also the cylindrical solid shank

expanded to become groove- filling by the blow of powder charge and gasses.

There were designed also the compression bullets in England (Wilkinson) and Austria

(Lorenz). Austria and several states of later Germany (not yet united, but a bunch of

independent principalities) were adopted 13.9 mm rifles since 1854. Swiss Colonel

Wurstemberger calculated already in 1840s that a bullet weighing 16 to 17 grams is able to

incapacitate a man or a horse at all sensible shooting ranges - up to 800 meters.

Recommended caliber was 10 millimeters. Pattern of these Jaeger rifles was contemporary

American target rifle, shooting pointed bullets wrapped into a paper patch impregnated

with sperm oil or wax & tallow mixture. (Discovery of American Alvan Clark).

British Wilkinson and Austrian Lorenz designed a compression bullet in early 1850s.

Austria and many German states adopted 13.9 mm rifles since 1854. Deep

"cannelures" around the bullet shank were not "grease grooves",

because bullets were paper patched. British Pritchett bullet was actually a smooth-sided

variation of Wilkinson bullet. It was noted that the "cannelures" were not

needed at all if the bullet is of almost pure (soft) lead and point of it is heavy.

British standard caliber was .477 since 1853. Standard bullet of Enfield rifle was,

however, a Minié projectile with a wooden "culot", shaped like a truncated

cone. Bullets of the Snider breech-loaders had culots of clay and shellack mixture or the

baked clay and usually the hollow point plugged with a wood peg or "overspun"

hollow point cavity. Soft and heavy bullets made severe bone fractures by hits on the

limbs, but the 13.9 mm Lorenz bullets produced more severe injuries in the soft

"wet" tissue, because of their higher striking velocity.

"Explosion-like" injuries were noted during American Civil War. Especially

Confederate troops had Lorenz rifles and ammo, imported from Austria.

The first lot of Swiss Jaeger rifles, issued to the sniper companies in 1848 were like

contemporary American Plains rifles with octagonal barrel. Bore was also octagonal, with

eight spiral V-shaped grooves. Caliber was 12.5 millimeters. Rifles were never "shot

in anger", but in many tests they were found to be effective up to 800 meters. Bullet

perforated two stacked fir boards (thickness 25 mm) and penetrated third one to depth more

than 10 millimeters at 800 meters. Recoil was, however, "like horse's kick".

Rifle was fit for use of elite troopers only; not for average riflemen. (In Switzerland

every adult male citizen "sound in body and mind" was and IS a member of

well-trained Militia. It is said that "in Switzerland there is not an Army:

Switzerland itself is an army". No country has been daring enough to try conquer it

since the era of William Tell, because the attacker shall meet an Armed Nation; not just

an Army).

Next generation of Swiss Jaeger rifles was made in 1851 according to idea of Colonel

Wurstemberger. Caliber was 10.4 mm, bullet weight 16.6 grams and powder weight 4 grams.

Effective range (three times "killing criterion") was up to 1000 meters.

Infantry rifles with 10.4 mm caliber were made since 1863, but in 1870 there was designed

a breechloader rifle known as Vetterli Model 1871. Not only breechloader but also a

repeater rifle with tubular magazine for eleven 10.4 mm cartridges, loaded with somewhat

reduced charge (3.75 grams) but heavier bullet (20.4 grams). Length of bullet was 25.5

millimeters. Muzzle velocity of it was 435 meters per second. Perforation of 25 mm thick

fir boards was at least three but sometimes four boards at 1000 meters.

Contemporary military rifles were breechloaders, usually not yet repeaters. Caliber of

them was ca. 11 millimeters (in Sweden and Norway, however, 12.17 mm with bullet diameter

.50" or 12.70 mm). Bullet weight was ca. 25 grams. Muzzle velocity of bullet was 420

to 465 meters per second. Bullets were of lead, alloyed with antimony and wrapped with

lubricated paper patch. Because the muzzle velocity of bullets was rather low and material

of them was "hardened" lead, they had surprisingly slight tendency to expand,

even when hit on the bones. Earlier Minié bullets were of almost pure lead. Diameter of

them was bigger and they were heavier than bullets in 1870s and 1880s. When hit on the

bone of arm, thigh or leg, they expanded and made severe fractures. During the Crimean War

and American Civil War amputation was a routine "cure" of direct bone hits on

the limbs. "Flesh wounds" were easy to heal, unless badly infected. Hits on the

abdominal cavity or thorax were usually fatal, but some veterans of American Civil War

survived by a good luck - despite of (not by) efforts of busy field hospital surgeons.

Neither Minié bullets nor "small caliber" bullets were able to cause massive

cavitation in the soft tissue, because the striking velocity of them was low. Bone

fractures made by hardened lead bullets were possible to heal without need to routine

amputations if the wounds were not badly infected. In the late 1880s and early 1890s

arrived the metal jacketed bullets to battle fields - mainly in the colonies. There were

not remarkable "wars between regular armies of civilized nations" after

Franco-Prussian War and a war between Turkey and Russia in 1870s. Along with the jacketed

bullets arrived smokeless powders. Caliber of military rifles was reduced to 8 mm, 7 mm or

even 6.5 mm. New smokeless propellants allowed pursuit of high muzzle velocities and

ranges up to 2000 meters or even more.

Typical full-metal jacketed bullet in late 1880s and 1890s. Caliber was reduced to 7.62 or

8 mm but soon to 6.5 mm. Some experimental work was done even with 5.2 mm projectiles.

Long range and deep penetration were pursuit of bullet designers. "Shocking" or

"stopping power" of these projectiles was soon found insufficient - especially

for the wars in the colonies.

Warriors in the British colonies were soon dissatisfied with these novelties. Small

full-metal jacketed bullets lacked the "stopping power" like that of heavy lead

projectiles of rifles like Martini-Henrys or still older Sniders, which shot still the

.577 caliber soft lead Minié bullets although they were already breechloaders. Muzzle

velocity of .303 caliber Lee-Metford bullet was not yet able to cause notable cavitation

in soft (muscle) tissue. Velocity was mere 580 meters per second with compressed

blackpowder load and 630 m/s with a charge of Cordite powder.

Bullet made just a stab or sting through the attacker, like a sharpened fencing foil. If

some vital organ or thick bone was not perforated, the attacker didn't sometimes even feel

the hit - or several hits. The savages in British colonies were anaesthetized themself by

the drugs or simply by the religious ecstasy (so especially in East-India). Hits of

jacketed bullets could be fatal afterwards, but they were unable to stop the assault

immediately. Just a hit through the brain or spinal cord above collar bones is able to

incapacitate (read: kill) a drug-crazy or fanatical attacker. Britons found soon that the

.303 British bullets were more efficient when they were shortened from the points so that

one millimeter of their lead core became exposed. Bullets were now flat-nosed and able to

expand. They were known as Dum-Dum bullets, since they were made by Dum-Dum Arsenal, in a

suburb of Calcutta, India. (Name means either "a clay rampart" or "a gipsy

camp"; Dama-Dama). Hollow-pointed .303 bullets made in England were less efficient.

Those bullets were banned in 1899 by the First Haque Peace Convention. The "latent

Dum-Dum" rifle bullets were, however, discovered very soon. Presumably first of them

was a German 8 mm Spitzer Geschoss, design of an independent ballistician Arthur Gleinich.

(He is unknown in Anglo-American and even the German literature). It was well-known that

high velocity of a projectile could cause "explosion-like effect" even when the

bullet is definitely non-expanding. In U.S.A. was actually designed a lathe-turned and

pointed solid mild steel bullet for .30-40 Krag rifle (a miniature artillery projectile

with a copper rotation band) already in 1894, but it was not adopted, because of poor

performance and accuracy at ranges beyond 1000 yards.

The first "latent Dum-Dum" bullet was design of German Arthur Gleinich in 1903;

officially adopted in 1905 by Germans, in 1906 by United States and in 1908 by Russians.

On the picture is Russian variation 08/-10 with a crimp groove, adopted for use in Maxim

machine gun (which could pull the non-crimped bullet away from a cartridge when it

snatched the cartridge from the belt). Long-range accuracy of this "Lyohkaya

Pulya" (= "light bullet") was poor, because diameter of it is no more

than 7.80 millimeters, while groove diameter of rifles and machine guns may be as much as

7.95 mm. Flight of the bullet is yawing and after the hit it tends to "capsize",

like all of these pointed bullets with short cylindrical shank. Russian bullet was

actually designed not for conventional warfare between regular armies, but for struggles

against socialists, separatists and anarchists.

Veterans of American Indian Wars told that usual shooting range was less than 400 yards

and many times less than 100 yards, but the "High Brass" of U.S. Army were

fascinated by daydreams about effective rifle fire up to 2000 yards. There were also

machine guns, like ten-barreled Gatling, able to shoot up to 1800 rounds per minute by

hand cranking or 3000 rpm by electric motor (tested by U.S. Navy in 1893). Germans were

more realistic when they adopted pointed ("Spitzer") bullet in 1905, although

they were constrained to renovate bores of their military rifles by deepening of the

rifling grooves. These projectiles have a very short cylindrical shank (about as long as a

groove diameter) and a long sharp point.

Designer A. Gleinich was terrified when he saw "spark photographs" of his

bullets emerging from the rifle muzzle and powder gas cloud: Bullets were inclined as much

as 45 degrees of angle from their trajectories. But in the target at 100 meters, holes of

them were perfectly round and the dispersion of hits was no more wide than hits of

old-fashioned Model 1888 projectiles. Accuracy of Spitzer bullets was on a par with M-88

roundpoint bullets to 300 or even 400 meters. Muzzle velocity was increased from average

630 meters per second up to 900 m/s. German rifle Model 1898 k had a barrel shortened to

60 centimeters, but because of improved powders the muzzle velocity of Spitzer bullet was

still 895 meters per second. Weight of M-88 bullet was 14.7 grams. Spitzer bullet weighs

9.8 grams (+ 0.2 gram).

Hit of the pointed bullet made horrible wound at "crossed bayonets' distance" up

to 50 meters, because of bullet's yaw and cavitation of wound channel in the soft tissue

like muscles. If the "wet" tissue (like liver or brain) is hit even with a full

metal jacketed bullet, the striking velocity 360 meters per second is able to cause

explosion-like effect. When the bullet hits through full stomach or urinary bladder, the

effect is also like an explosion inside the abdominal cavity. Weight of the roundnosed

non-expansive jacketed bullet may be mere 5.5 grams - or even 4.7 grams (although the

striking velocity of 7.65 mm Browning /.32 ACP bullet is considerably less than 300 meters

per second). Placement of hit is decisive; not the weight of projectile or Joules/

foot-pounds readings of them. I presume that the armed citizens have slain more would-be

robbers or rapists, burglars and street-muggers with .25 ACP / 6.35 mm Browning caliber

vest-pocket pistols than with the .45 ACP handguns and the Magnum caliber revolvers

altogether in streets, alleys and homes.

But now back to the war theatres: Before the 1st World War were many countries adopted

Spitzer bullets with high muzzle velocity and a center of gravity in the base end of the

bullet. In U.S.A. the production licence was bought from A. Gleinich in 1906. Russians

adopted their "Lyohkaya Pulya" in 1908. Britons adopted officially their Mark

VII bullets in 1914, just before or soon after outbreak of 1st World War. Bullet Mk VII is

in appearance similar to pointed bullet Mk VI but lighter. Inside it is shortened

cylindrical lead alloy core in the base end of jacket and a separate point-filler of

aluminium or "Fiber" inside the bullet point. (Fiber was presumably cotton flock

or wood pulp impregnated with phenol-formaldehyde/ Bakelite plastic and compressed in

heated mould to become a hard point filler. Bakelite and many other kinds of the

"Phenoplasts" were well-known materials since 1909).

British .303 Mark VII "latent Dum-Dum" bullet has also center of gravity moved

backwards, but the shank of it is not shortened. There are two cores inside an intact

jacket. A conical point filler is of material with considerable lower specific gravity

than that of lead alloy of a core. These materials are aluminium or Fiber (presumably

Phenoplast). According to some non-confirmed rumors the Mk VII bullets with aluminium

point filler were designed for warfare against armies. Those bullets with Fiber point

filler were issued to troopers fighting against "savages" in the British

colonies. They capsized after hit still more easily than bullets with aluminium point

filler.

Idea was again to move bullet's center of gravity rearwards but to keep appearance of

bullet and length of cylindrical shank unchanged. Idea of modern hollowpointed match-grade

bullets is same, but use of HP projectiles was banned in ground warfare by Haque

Convention in 1899, as mentioned previously. All of the "latent Dum-Dum" bullets

have intact jacket on their points and lead core (plus the tracer capsule of tracer

bullets) crammed to the jacket from base-end of bullet. Most usual way to get a

"Dum-Dum effect" without violation of Haque dictates is to design a pointed,

base-heavy bullet with a high muzzle velocity. Russians dimensioned their L-bullets like

German S-balls, but considerably slim when compared with the groove diameter of

Mosin-Nagant Model 1891 rifles and Maxim machine guns.

Needless to say that these balls emerged from the bores with considerable yaw. Russian

bullets "Lyohkaya Pulya" models 1908 and 08/10 were not designed for warfare but

for riot control at less than 100 meters shooting distances. Drawback of them was a rather

short accurate range. Sniping was impossible during the 1st World War, if there were no

more available cartridges with old model 1891 bullets. When these cartridges ran out,

there were 7.62 mm ball ammo accurate enough for sniping in production not until 1930,

with a sole exception: Armor penetrating bullets with a copper point cap. They were,

however, issued mainly to the machine gunners. Wounding effect of AP bullets was less

dramatic than bullets model 1908.

Japanese 6.5 mm "latent Dum-Dum" bullet with a tumble effect similar to British

Mk VII. Jacket is thick in bullet point and very thin in the base end. Material of jacket

had lower specific gravity than that of core lead. Therefore the bullet is

"base-heavy" and prone to capsize after hit. According to very scarce Japanese

sources of information the thick point jacket was needed for warfare in jungles for

perforation of bamboo trees and frozen trees in mountains during wintertime in Manchuria.

According to malevolent rumors (propaganda), the core lead was very soft, almost pure, and

the rear jacket was so thin that the base end of bullet became expanded easily or crooked

after the hit and tumble.

"What is the truth?" I don't know! This Japanese bullet is least known

mass-produced projectile to me. I don't know even the year of it's adoptment. Japanese

rifles and carbines were in use during Finnish First Independence War (1918) by the

troopers of our Civil Guards, White Army and revolting socialists, but the 6.5 mm Arisaka

cartridges had old-fashioned roundpointed bullets in 1918.

It is very difficult to compare effects of old musket balls, Minié bullets, hardened lead

projectiles, old jacketed bullets, Dum-Dum bullets (true or latent) and more recent

innovations in the human body without "empirical/clinical experience", and due

to continual lack of relevant literature (it is always "out of the print").

Also, it is a well-known fact that from some ten thousands of gunshot wounds, there are

not even TWO of them quite alike! I have not also enough time to describe all the methods,

how to make the bullets more lethal or improve wounding effect of them by visible or

intrinsic asymmetry or the "odd" shape of bullet points. About "more recent

innovations" is among the most clever ones a Russian 5.45 mm bullet for AK-74 assault

rifle, by it's "sliding ballast" principle.

Bullet is about miniature of Russian 7.62 mm LPS

bullet (= "Lyohkaya Pulya s Serdtse" = "light bullet with

core"), a copy of German 7.9 mm S.m.E ball, having a mild steel core inside the

boattailed steel jacket, with slight improvements. Ahead of the steel core is a tiny

cylinder of lead alloy, containing little percentage of arsenium. Between the steel core

and jacket is a thin lead alloy sleeve or "bearing". Tip of the bullet point is

empty. (See the drawing). Bullet diameter is considerably smaller than groove diameter of

the bore. Actually it is not difficult to push the bullet through a bore with steel rod

and few taps of a light hammer or mallet. But when the powder gas strikes on the rear end

of steel core, moving it forwards, the bullet's shank expands just like the shank of an

old Minié projectile.

Bullet is about miniature of Russian 7.62 mm LPS

bullet (= "Lyohkaya Pulya s Serdtse" = "light bullet with

core"), a copy of German 7.9 mm S.m.E ball, having a mild steel core inside the

boattailed steel jacket, with slight improvements. Ahead of the steel core is a tiny

cylinder of lead alloy, containing little percentage of arsenium. Between the steel core

and jacket is a thin lead alloy sleeve or "bearing". Tip of the bullet point is

empty. (See the drawing). Bullet diameter is considerably smaller than groove diameter of

the bore. Actually it is not difficult to push the bullet through a bore with steel rod

and few taps of a light hammer or mallet. But when the powder gas strikes on the rear end

of steel core, moving it forwards, the bullet's shank expands just like the shank of an

old Minié projectile.

Powder gasses leaks into the gap between truncated-cone shaped rear end of steel core and

the jacket, accomplishing so-called "Gaspolster effect". The thin lead

alloy sleeve between steel core and jacket seals the gap before the Gaspolster (powder gas

expansion) proceeds too far towards the bullet point and cause too high chamber pressure

by the excessive friction between bullet jacket and the bore. Sleeve itself expands and

distends also the jacket, which fills now the rifling grooves. The steel core acts as a

valve which prevents leak of lead alloy from the sleeve to the point space of bullet. The

lead cylinder ahead of steel core is now squeezed into the conical hollow space of bullet

point, leaving just the tip of it still empty.

The X-ray photographs of spent 5.45 mm bullets shows that the lead cylinder (or now a

truncated cone) is always more or less asymmetric. Alloy of lead and arsenium (metallic

arsenic) squeezed into the conical space get always more or less uneven frontal surface.

The bullet is very long when compared to its diameter. A steep twist of rifling is barely

able to keep it stabilized in flight, but the muscle tissue of human being or animals (and

the transparent tissue simulant; Ballistic Gelatine) is about 800 times as dense as the

air. Even the trifling intrinsic asymmetry of bullet is able to cause tumble of it after

hit and penetration to depth of just few centimeters.

Muzzle velocity of 5.45 mm bullet is slower than was estimated ca. 20 years ago (about 900

meters per second from AK-74 rifle) and in general the internal ballistics of a cartridge

M-74 is like that of .222 Remington rather than 5.56 mm NATO ammo, but the long, slender,

pointed and boat-tailed bullet keeps it's velocity very well, owing the high Ballistic

Coefficient in its caliber class. Flight of it is said to be "arrow-like", not

yawing like flight of pointed flat-based or hollow-based bullets like Russian LP 1908/-10.

Even the visible asymmetry of the bullet is unable to deteriorate accuracy, if it is

located close to the central axis of bullet and on the point end of it. (The slightest

asymmetry on the base end of bullet shall turn it far away from it's trajectory. The fact

known more than a hundred years ago). Each bullet with "mutilated" point should,

however, have similar air resistance/ Ballistic Coefficient and weight. Intrinsic

asymmetry should also be located into the point end of bullet and not too far from the

central axis of it, but the Ballistic Coefficient/ air resistance remains unaltered.

Weight of the bullets should not be too much variable, of course.

Source of drawings: "ASE-ATLAS" by A.B. ZHUK (Russia/Finland). Distributor of

Finnish edition: kirjamyynti@aselehti.fi .

0403 MMII; PT.

PHOTOS OF DeLISLE SILENCED CARBINE

An American (Michael, California) asked you for photos of the DeLisle Carbine. In my own

collection is No. 1015, produced in Fort Dagenham (one of the No. 1001-1017), and the

'survivor' from the test 2/1944 in Cheshunt. It became later a present from Sir Malcolm

Campbell (Combined Operation H.Q.) to Mr. Dinely (owner from Bapty), and remained in the

Bapty collection for many years. I would help Michael with photos, if he wants....;

perhaps you can give him my e-mail-address.

Thank you very much best wishes Dr. Richard, Germany

I've lost

e-mail address of Michael long time ago. You may, however, send the photographs of your

DeLISLE carbine to our editorial office for publishing on GOW by the Web or as the paper

prints to our P.O. Box. Not only Michael but also many other visitors are eager to see

this rare piece of equipment.

1502 MMII; PT

MY L-39 IS NOW SHOOTABLE

I finally finished the repair on my L/39 and was able to test fire today. I am happy to

report that the repair is successful and we fired 15 rds. I do need to make a new gas port

plug. I copied the original piece -that was in the gun and put only one 1mm port in it.

Unfortunately there was sufficient space around it in my gas cylinder to allow leakage and

that was enough to cycle the action. I even had the port on the opposite side of the plug

from the gasport in the barrel.

I fired one round with my brass 153 gram projectile and the pressure was high enough with

the leakage for the extractor to tear a section of the rim out. The rest of the shots were

fired with 88 gram military surplus projectiles and they had no problems with pressure. I

crimped two of the necks in order to test the cycling and feed with the magazine installed

and semi auto fire is easily accomplished.

The recoil with these light projectiles was not unpleasant and the 3 of us shooting today

all agreed that the Kar98K we had fired earlier was more painful to shoot. I found the

hang-fire type problem you mentioned as a possiblity did occur on the second round fired

from the magazine. Probably recoil moved the powder away from the primer and caused this.

Does that sound possible? I will use the blank powder as an initiator in the future as you

suggested. What would be a proper amount to use for this??? The powder I have came from

British manufactured .303 Bren gun blanks. I have also heard that some are using Black

powder for this purpose.

I will send some pictures via email and also via normal mail as soon as I can get them off

the camera. I'll include dues for this year as well....

Thanks. Frank, USA

Comments.

Germans did use routineously the blackpowder booster charges in their 20 x 138 mm

anti-aircraft cannon cartridges. Those 20 mm FLAK guns had a recoil action, but the German

and Italian FLAK cartridges were shot also from L-39 rifles and VKT-40 anti-aircraft

machine cannons. Jams of the gas piston mechamism were not noted, but the smoke of

blackpowder booster charges made the spotting somewhat difficult in calm weather. Cleaning

of a-t rifles and a-a cannons was also more laborous after shooting with German and

Italian ammo. According to memoirs of AIMO J. LAHTI, chemists of VihtaVuori were designed

an 8 mm PN Sinoxid primer for 20 mm cartridges so "hot" that the booster charge

wasn't needed at all to ignite the main charge, but the Finnish High Brass officers were

"fell in love with gunsmoke of German ammo". Therefore the Finnish 8 PN VV SX

primers weren't adopted for the Finnish-made 20 x 138 mm cartridges. Finnish Army officers

accepted reluctantly use of smokeless blank cartridge powder instead of blackpowder in the

bagged booster charges (rammed between the case bottom and main charge).

Use of a booster charge is beneficial if not essential for regular ignition of main

charge. I don't know characteristics of British .303 blank powder. Try first 12 to 13

grains of it, bagged into an empty tea bag. Sew the open mouth of a bag closed with cotton

thread. Ram carefully the bag onto bottom of the resized and primed case. Then pour

somewhat reduced main charge into the cartridge. You may (should?) fill the space between

main charge and base of the projectile with Dacron or tissue paper to keep the booster

charge close to the vent hole(s) of primer, even if the paper of a tea bag shall become

torn. In factory-loaded 20 x 138 mm cartridges were materials of booster charge bags

natural silk (or Chardonnet's artifical silk; fibres of nitrocellulose; "collodion

wool") or cotton gauze, presumably impregnated with potassium nitrate, if not

nitrated with nitric acid to become self-consuming. Tea bag is, however, suitable

surrogate for test-shooting.

PS. The book about life and works of AIMO JOHANNES LAHTI is recently published in Finland.

It contains an English summary and captives of photographs are bi-lingual; also in

English. Name of this book is "AIMO LAHTI - Asesuunnittelun suuri suomalainen"/

"Aimo Lahti - the great Finn in weapons' design", by MARKKU PALOKANGAS and MAIRE

VAAJAKALLIO, with English summary and captives by JOHN E.O. SCREEN.

Published by ASE-lehti Oy, P.O. Box 161, FIN-90401

OULU, FINLAND, EUROPE. E-mail of distributor: kirjamyynti@aselehti.fi . Printed in Loimaa,

Finland, 2000. (C) Markku Palokangas 2000. ISBN 952-91-2548-8.

1602 MMII; PT

"HUMBERT DESIGN" SUPPRESSOR FOR .22

HANDGUNS

Dear Mr. Kekkonen; Great posts, I have learned a lot from post to post as far as

suppressors go. I reside in Central America and information on this subject is basically

non-existent. I have been around the suppressor world for a couple of months, I have built

several of them for .22 cal. pistols but haven't quite found the combination of tubing

length and I.D. number of baffles and baffle spacing. At the moment I am using a 6061 T6

Alum. tubing with an I.D. of 15/16". I work well with lathes and could make the

"M" shaped baffles, but I don't know if there is a considerable difference in

suppression when using flat disks with a 6.35 mm center hole with spacers on the other, is

it worth the effort?

Basically, and sorry to bother you so much, if you could guide me as to: how long of

tubing should I use, how long should my first expansion chamber be, should my first washer

have a diffractor in it and what would be a suitable amount of baffles and spacing between

them to achieve optimum suppression. My initial washer center hole diameters are 7 mm, the

disk centerholes are 6.35 mm and the end cap is 8 mm. So as you can see I have been

fooling around with so many designs I finally confused myself. If you could give me some

advice I would greatly appreciate it.

Sincerely; Ing. Daniel (Guatemala)

Tubing with

I.D. 15/16" is sufficient for suppressor jackets of .22 rimfire guns. Length of the

jacket may be as short as 170 - 180 millimeters for .22 rf rifle suppressors, measured

from the rifle muzzle to front face of end cap. If the barrel is shortened, the suppressor

should be lenghtened. The length 170 mm is O.K. if barrel length is 61 cm (24 inches or

more). For 22 inch (56 cm) barrel the suppressor length 180 mm is sufficient. For .22 LR

target pistol with barrel length usually 152 mm (6 inches) should length of a suppressor

be at least 200 mm but preferably 220 mm. For the autoloading handguns is length more than

200 mm unnecessary, because noise of autoloading cycle exceeds the noisiness of a report.

If the bullet velocity exceeds the sonic velocity in ambient air, suppressor is useless at

least on .22 caliber rimfire rifles: Flight noise of the bullet is more loud than a muzzle

blast of non-suppressed rifle.

The disk-baffle and spacer construction is presumably oldest one used in the suppressors.

Year of discovery is unknown. Inventor was Colonel HUMBERT, probably a citizen of Imperial

Russia (despite of his French name). In Russia was patenting unknown practice during the

era of Imperial and Soviet administrations. Many Russian inventors remained therefore

unknown in the Western world, although their discoveries were and are well-known, like

wireless telephone (invented by ALEXANDR S. POPOV several years before patenting of the

wireless telegraph by GUGLIELMO MARCONI), or metal ring obturator seal of cannon breech

with sliding block (invented by LEWIS WELLS BROADWELL, a resident of St. Petersburg,

Russia. Protected by British Patent in 1863, but the "nominal patentee" was

British patent attorney of L.W. Broadwell. Inventor himself was not justified to apply

patents even abroad).

You may made the baffles or diaphragms for your suppressor by lathe-turning from aluminium

or plastic bar. No more than five baffles are needed. Sixth one is the end cap. The very

best material for baffles is "DuPont Polymer 66", known by trade-mark NYLON. It

is self-cleaning, because it's molecules contain some water, especially in the Nylon

bar-stock. This water cooks off the powder and primer residue. So it prevents accumulation

of residues on the flat surfaces of baffles and especially on the walls of bullet passage

holes.

My experience in late 1970s told that the thickness of the baffles should be at least 5

millimeters in the short model (rifle) suppressor and up to 6 mm in the long (handgun)

suppressor. Spaces between the baffles, and from the frontmost face of a baffle stack to

the rear end of the end cap, may all be 5 millimeters. The Nylon baffles should be turned

to the inside diameter of suppressor jacket tube + about 0.05 mm; i.e. to the

"compulsion tightness" into the jacket. You'll need a heavy hammer for forcing

frontmost baffles and an end cap into the jacket tube from the mouth of suppressor jacket.

Idea is that each of the baffles is stuck into the jacket by it's friction. The spacers

are needed for spacing the baffles 5 mm apart from each other when a column of them is

forced into the suppressor jacket, but also for direction of powder gasses to the rotation

around central axis of chambers between the baffles.

I made the spacers from aluminium sheet, thickness 1.0 millimeter. Width of the sheet

strips was 5.0 mm and length of them 4 x I.D. of the brass tubing jacket of my

suppressors. I bent the ribbons with the pliers to shape of "at" mark (@),

placed them on the ingoing baffle and placed the next baffle or end cap on the sligtly

chamfered mouth of the suppressor jacket, and forced them into the jacket by the blows of

a hammer. You didn't tell the wall thickness of your aluminium tubing (the jacket material

of your suppressors), but if it is ca. one millimeter, you can use it as a material of the

spacers: Lathe-cut the ring-like pieces (lengt 5 millimeters) from the tubing. Split them

and bend them to shape of @-mark.

The end cap of your suppressor may be simply like a Nylon baffle, but hammered to depth 2

or 3 millimeters below the mouth of your suppressor jacket. The closure of the jacket

mouth may be done just as the "roll crimp" of the old-fashioned shotshells, with

a turning lathe. I closed the mouths of my brass-jacketed suppressors by filing six

V-shaped notces on the edge of jacket mouth and beating the closure with a hammer. I shot

about 8000 rounds of .22 LR cartridges (including a hundred of CCI Stingers and 150 rounds

of Winchester Xpediters) through this suppressor, mounted on the REMINGTON NYLON 66

autoloader .22 LR rifle. The suppressor mouth closure didn't show any signs of failure

when I sold the rifle away along with the suppressor.

You may calculate by simple arithmetics that there is a large gas expansion chamber

between the muzzles of especially handguns and the rearmost baffle of the suppressor. It

is needed, because most handguns are autoloaders, puffing the powder gas backwards and

spitting unburned powder kernels backwards unless there is an expansion chamber between

muzzle and baffle column. Diameter of the bullet passage apertures (center holes) of the

baffles may be as small as 1/4 inch (6.35 mm) in the rearmost baffle or two of them, if

the mounting of suppressor is precise - coaxial with the bore of a gun, and concentric.

Next pair of baffles may have 7 to 7.5 mm passage and frontmost pair of them 8 mm

aperture.

As far as I can recall, I had 7.5 mm holes through all of the five baffles and end cap of

my brass-jacketed suppressor for Remington Nylon 66 rifle, but in Guatemala you may meet

some Mexican (truly subsonic) cartridges like AGUILA .22 SSS with marginally stable

(exceedingly long) bullets, which may fly through the suppressor somewhat yawing. If

somebody like to shoot these cartridges from suppressed handgun, diameter of the bullet

passage 8 mm of each baffle and end cap (frontmost baffle) is highly recommended.

This kind of suppressor is a "sealed unit" like the old MAXIM

"silencers" or BR-Tuote Reflex Suppressors:

When assembled, it is almost impossible to disassemble. Material of the Maxim and BR

suppressors was and is mild steel. They are easy to clean with almost any detergent

(including the highly alkaline solution of sodium hydroxide, sold in Finland as the

"sewer opener" and "dish washing machine detergent"). Aluminium jacket

and spacers does not stand the alkaline detergents; even the strong solution of sodium

bicarbonate. If needed, neutral oil products are recommended for soaking the

powder/lead/bullet lube residues away from the suppressor. A good and safe cleaning

solvent is mixture of turpentine and kerosene (lamplight oil), fifty : fifty by weight or

volume.

Plug the mouth of suppressor, pour the mixture into it's jacket up to the mounting device.

(You may also plug the rear end of a suppressor or just keep it in vertical position). Let

the solvent to take effect at least 24 hours; then pour it away, mount the suppressor on

your gun and shoot two or three shots through it. These directions are not "in my

experience", because I never noted need to clean my brass-jacketed Humbert pattern

suppressor with Nylon baffles and aluminium spacers. Cleaning may be needed after shooting

20 or 30 thousands rounds of ammunition. I shot somewhat less than 10 000 rounds through

my suppressor.

1902 MMII; PT.

"SNEAK M-39" RIFLES AND SERIAL NUMBERS

I have enjoyed your site for some months now. I have learned a great deal about the

history of the M-39 and Finnish history.

I have two M-39 rifles: excellent shooters in like new condition, both are dated 1970 with

a serial number and do not have ANY OTHER markings, except a boxed "SA" on one

of the stocks and "3600" on the left side of both barrels next to the stock (to

the left of the serial number). Stamped on the barrels are the serial numbers: 304347 and

305340 respectively. I have read that the low known number of 1970 is 306,135 and the high

of that year is 306,420. Neither of my rifles fall within this range. Both were imported

by Interordance and sold to me from Wholesale Guns and Ammo, Inc. What are your thoughts

on these serial numbers?

Take care; John

The boxed

stamp "SA" means "Suomen Armeija" (Finnish Army). From the

"sneak M-39" rifles may be found stamp "AV 1" or "ASEV 1",

but many times the Arms Depot Number One didn't stamp their logo on the barrels at all.

Just these barrels were made by VKT and SAKO Oy during our 1941 - 44 War but not yet

finished or stamped by barrel manufacturers. They were selected and of top quality as you

told. (Hell-of-a good shooters!). I have still not much information about production of

the sneak M-39s, and I afraid that I'am never able to tell the whole story of these

rifles.

Stamp "3600" is unknown to me. Your rifles may be assembled in 1969 but date is

stamped in 1970 for the sake of misleading, or the serials were stamped on the barrels

before year stamping on the assembled rifles. It seems to be impossible (to me) to get any

information about quantity of produced sneak rifles, and range of their serial numbers.

These rifles remains still "sneaky" in Finland although our arch enemy, Soviet

Union, demolished more than a decade ago. I have seen just one of sneak rifles

(year-stamped in 1968) hanging on the wall of my very good friend living on my close

neighbourhood.

1202 MMII; PT

STILL ABOUT "SNEAK RIFLE M-39"

One of these rarities is, as I formerly mentioned, on the wall of my neighbour, a retired

Finnish Artillery Major living within five minutes of walk from my home. (And my steps are

short, because of my too narrow coronary arteries). The very rifle of my friend is

presumably among the first batch of Sneak Rifles; assembled by Asevarikko 1 in Kuopio.

Receiver of it is made in Imperial Russia. It is octagonal. The original factory-stamps

and Russian coat of arms (twin-headed eagle) were ground away before re-blackening of

receiver and other steel parts.

On the rifle are stamps as follows: Year of assembly "1968". Assembler's stamp:

"AV 1". (Seemingly omitted from the rifles assembled in 1970 or later). Serial

number on the barrel is "303 493". Manufacturer of the barrel is unknown, but it

is either VKT or SAKO surplus barrel, finished from unstamped blank, because barrel is

dimensioned exclusively to rifle M-39; not cut and modified from some Mosin-Nagant barrel.

2002 MMII; PT

M-85 SNIPER RIFLE STOCK

Dear PeTe, Please keep up the good work. I am interested in who made the stock for the

M-85 sniper rifle. If possible would you have any idea where I could purchase one of those

stocks? They are totally unavailable here in the US. If the stock for the M-85 is not to

be found do you have any idea of where I could purchase a Mosin-Nagant stock with an

adjustable cheek piece?

All the best, Joe

Designer of

M-85 sniper rifle (7,62 TAK 85), nowadays retired Border Guard's master-armorer ERKKI

TORO, lives in my neighbourhood in Lehmo, Kontiolahti, less than five kilometers from my

home. He had a small one-man's gunsmithing shop still a couple of years ago, but he was

hesitant to produce the rifles for export. Too much bureaucracy; you know...

Stocks for the TAK 85 of Finnish Army were made by ASEVARIKKO 1 (nowadays KUOPION

ASEVARIKKO), an Army Arms Depot which is not justified to export. Metal parts and trigger

mechanisms were modified or made by VALMET Oy/ Tourula Works, which was integrated to SAKO

Oy in late 1987 and discontinued the firearms production gradually until mid-1990s. You

didn't tell, whether you have already the metal parts of TAK 85. Those parts of

Mosin-Nagant M-91 or it's variants (other than TAK 85) are impossible to bed easily into

stock of TAK 85. Receiver of this sniper rifle (in Finnish "Tarkka-Ampujan

Kivaari") has the heavy "bedding sleeve" with two recoil lugs ahead of

original receiver. Tang of the receiver is no more fastened on the stock. Long and stiff

bedding sleeve only is in close contact with the stock wood, tightened with two srews.

Receiver hangs free in the mortise of the stock. There is no more the bending stress

applied to the receiver.

Please, don't ask from me "where I could purchase". I simply don't know...

1802 MMII; PT.

UNKNOWN HUNGARIAN (?) HEADSTAMP

I have a question that I can't seem to answer. I have a rimmed 8 mm cartrige with a lot of

similarities to an 8 x 56R Hungarian rimmed cartrige but has a head stamp with the eagle

over swastika, the Roman numeral VIII, and the date 1938. I can't find any information on

this round and believe that it might be a rare collectable. If you can identify this round

I would appreciate it greatly.

Thanks Marty

Cartridge is

originally Austro-Hungarian 8 x 56R, loaded by Austrian WOELLERSDORF (Munitionsfabrik

Wöllersdorf) manufacture in August 1938. Soon after the German-Austrian

"Anschluss" to Third Reich confederation, there were a stylized version of

German eagle on the six-o'clock position of headstamp, but the eagle-on-swastika was

adopted in May or June 1938. Cartridges were, however, headstamped also with stylized

eagle until the stamp dies were worn out, until late year 1938 or early 1940.

"Reichsadler" stamp (eagle-on-swastika) was in use until 1945.

Former stamps of Woellersdorf cartridges were: Twin-headed (Imperial Austro-Hungarian)

eagle since 1880s until 1933 and one-headed eagle with a shield since 1933 until 1938.

Year and month stamps were always similar: Topmost (12 o'clock) is the month stamp: Roman

numerals I to XII. Century stamp 18 or 19 on the left (9 o'clock) side, and decade &

year stamp (example given: 38) on the right side (3 o'clock) of primer. These stamps are

divided by four radial lines, like on almost all Austro-Hungarian headstamps of centerfire

military cartridges. I am unfortunately unable to estimate rarity of your cartridge, but

at least it is now identified.

1302 MMI; PT

SAVAGE MODEL 1914

The Savage slide-action hammerless repeater, Model 1914, was discontinued in what year?

I've read your site, but I still can't find the answer to this question. Any help would be

appreciated.

Brenda

If it is a

shotgun, this "repeater" is Model 520, introduced in 1904 (NOT in 1914). It is

among the first hammerless designs, but not first one: ROPER & SPENCER pump-action

shotgun was already hammerless. R & S gun's U.S. Patent was issued in April 21st 1885.

Production of Savage (until 1920 actually STEVENS) Model 520 hunting guns was discontinued

in 1930, but many M 520 riot (fighting or police) guns were assembled from spare parts

until 1932 and issued to troopers still in mid-1960s. Shortage of spare parts was,

however, a scourge already during the Second World War.

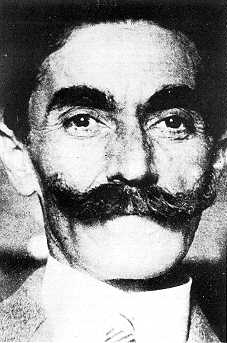

Designer of Stevens M 520 was JOHN MOSES BROWNING. U.S. Patent No. 781 765 was granted in

February 7th 1905, but Browning was sold the manufacturing rights of this gun to J.

Stevens Arms & Tool Co. already in the spring of 1903 and the production of it was

started about a year later. Firm SAVAGE ARMS Co. acquired Stevens A & T Co. in 1920.

Shotgun M 520 is therefore known as Savage-Stevens. After some "cosmetic

changes" the M 520 became known as a Savage M 620, but old Model 520 riot guns were

issued to the U.S. and South-Vietnamese troopers still during early years of Viet-Nam

conflict.

You didn't tell, whether the "slide action hammerless repeater" is a shotgun (I

think so), a centerfire rifle or a rimfire rifle. It is not "mea culpa" but

"tuus culpa", if my answer is incorrect.

1302 MMI; PT

LOADS FOR SCHMIDT-RUBIN 1889

Dear Pete, I wondered if you could direct me to some information on loading cartridges for

the 1889 Schmidt-Rubin? I was considering swaging down .308" lead bullets to

.304" to try to duplicate the old 1890 cartridge.

Thanks. David.

Actual

diameter of the soft lead bullet may be .303", because it is beneficial to use a

lubricant-impregnated paper patch/jacket/envelope wrapped around the projectile. Nominal

bullet weight may be 200 grains, because the specific gravity on cast bullet of almost

pure lead is higher than that of usual cast bullet alloys. (You didn't tell, whether

you'll cast your projectiles or use some factory-made cast or swaged .308" bullets).

Original paper-patched Schmidt-Rubin bullets weighed 210 grains and the cartridges were

loaded with 29 grains of Swiss semi-smokeless powder.

If you can acquire Finnish VihtaVuori "submachine gun powder" number N330, you

may load with 15½ grains charges of it for about 1970 feet per second muzzle velocity

with lubricated paper jacketed lead bullet, weighing 200 to 210 grains. This load

duplicates ballistics of the original Swiss S-R Model 1889 cartridge. If the shape of

bullet points and bases are similar to original S-R bullet, the trajectory of your bullet

is matching with the graduation of your rifle sights. In Metric (scientific; not archaic)

units of measures and weights bullet weight is 13 to 13.6 grams. Suggested (calculated;

NOT TESTED) charge of VV N330 powder is 1.0 gram and muzzle velocity of bullet is 600

meters per second (at best! May be lower). If your cartridge cases are old, use the black

powder only for reloading of them.

1402 MMII; PT

ARTICLE ABOUT MP 28

Pete, can I get that article in English? I have gone thru many times trying to decipher

the Finnish and cannot get much!

Thank you; Kymm

Sorry, you can

not! I have not enough time for translation of articles.

1502 MMII; PT

HAENEL ORIGINAL AYDT

My father brought back a gun from WW2, I have only information I have pulled off the

weapon itself. On the barrel it has stamped "Haenel Original AYDT". It also has

stamped "8.15 x 46 Norm" on the barrel. The breech lock has stamped

"Original Syst AYDT 19312". I am guessing that the number is the serial number.

I am currently missing the trigger system as well as the rear sites. I am also guessing

that I am missing several other important pieces. I am trying to locate general

information on this particular weapon as well as approximate value. I truly don't think I

could sell it because it was given to me and my father when I was a sniper with the 2nd

Rangers and I have always had a fascination with this weapon.

Any help you could give me would be of great help. If you need more information from me I

can provide, as well as a picture if needed. Thank you for all your assistance.

Sincerely, Kevin

AYDT is the

system (action) of your rifle; about similar to falling block of SHARPS-BORCHARDT rifle,

with the "linkless linkage" between breech-block and the opening lever similar

to MARTINI-HENRY rifles. A hammer, concealed into the breechblock, along with it's

V-shaped mainspring is similar to the hammer of ANSON-DEELEY shotguns. Aydt's mechanism

was copied all'round Europe, including Finland. Firms TAMPEREEN ASEPAJA and JOONAS

MATARAINEN made "schuetzen" rifles with Aydt action. Finnish team of shooters

had the rifles made by J. Matarainen in the Olympic Game of Stockholm, Sweden, in 1912,

but because of the weak cartridges of them (8.15 mm x 46R) they could not get good or even

fair records in the windy weather.

Tampereen Asepaja produced rifles chambered for 7.62 x 54R cartridges with Aydt action,

and the German GUSTLOFF WERKE designed also the anti-tank rifle model Pz.B. 39 with about

similar falling block action just before the Second World War, and the vertical wedge

breech-block was common action of many anti-tank cannons, caliber up to 45 - 50 mm.

Caliber 8.15 x 46R was about 100 years ago amongst the most popular in Central-European

centerfire target rifles; heavy-barreled "schuetzens" ("Stutzen" in

German and "tussarit" in Finnish). They were designed for shooting usually from

standing position only, but sometimes from kneeling. Prone position was common for

shooting with military rifles only; "not for sporting of the gentlemen". A

cartridge 8.15 x 46R was designed by firm FROHN at Suhl, Germany in mid-1890s. It became

soon THE cartridge for 200-meters offhand target shooting in Germany and Austria. I

presume that the cartridges are loaded still in Germany with copper-jacketed bullets.

Original ammo had lead bullets, and they were available with a choice of bullet diameters.

Every schuetzen shooter could seek and find the cartridge fit for bore of his/her rifle to

get a good accuracy.

Reloading of cartridges was also popular among the schuetzen shooters (so especially in

Finland still in 1920s), and there were some tricks how to make the cases almost

everlasting (unless the integrated anvil of Berdan primer pocket was chiseled away by

careless use of chisel and mallet). The stamp "Norm" on your rifle means that it

was possible to shoot factory-loaded cartridges with "normal" bullet diameter

and to get a good accuracy even with jacketed bullets. If the bore/ groove diameter was

smaller than normal, use of lead alloy bullets was recommended. Stamp "19312" is

presumably a serial number of your rifle.

Manufacturer C.G. HAENEL WAFFEN- UND FAHRRADFABRIK, in Suhl (established in 1840) was

occupied by Russians in 1945. I afraid that all the records of it's products (from air

rifles and vest-pocket pistols to assault rifles Modell 1944) are lost forever. Haenel

made also shotguns and combination guns until the end of Third Reich, but during the era

of Communist administration the best known Haenel products were air rifles. Production of

single-shot target rifles with Aydt action continued presumably until the Second World

War. In 1935 they were plentily available.

I am unable to estimate value of your rifle, because the trigger mechanisn (usually a

double-set one with a "hair trigger") and rear sight (usually a "peep

sight" with a very small aperture, mounted on the upper tang behind action) are

missing. Spare parts for these old target rifles are usually hard to find and difficult to

reproduce.

1502 MMII; PT

ACIER 170 SHOTGUN

Hello, I am desperately trying to find any information on an Acier 170 shotgun. Do you

know any web sites that might help?

Thanks! Andrea.

Word

"acier" is French, means "steel", and "170" may be a grade

of steel. I presume that your shotgun is a Belgian gun made by unknown manufacturer.

Nobody is able to find out producers of shotguns and revolvers of Belgian origin unless

there is a real factory brand stamped or engraved on them. I have no direct contact to the

Web and no skill to seek anything from it. So; I am unable to help you. Sorry!

1502 MMII; PT

HANDLOADING OF PINFIRE CARTRIDGES

Is anyone firing the old European pinfires? Or know how to make the rounds. Is this a

ridiculous venture?

Karl.

One of my

friends has reloaded and shot 12 gauge pinfire shotshells successfully. There is an

unsolved problem hindering loading of pinfire handgun cartridges: Lack of suitable

primers. For 12 mm and 15 mm LFx revolver cartridges the percussion primers number 11 are

O.K., but in Finland 7 mm and 9 mm LeFAUCHEUX revolvers are most common. Diameter and

height of N:o 11 percussion cap is too large for these small-caliber cartridges. Another

problem is lack of knowledge about dimensions of pinfire cases and cartridges for

revolvers.

It is possible to form pinfire cases for 9 mm LeFAUCHEUX cartridges from the empty jackets

of .357 caliber bullets, and the modern plastics are practical materials for internal base

wads of cases. You should disassemble some original pinfire cartridges and measure

dimensions of them for reproduction. Unfortunately you didn't tell caliber of pinfire

cartridge you'll try to reproduce. Therefore I am unable to tell, whether your venture

shall be ridiculous or successful.

1602 MMII; PT

CLARUS-PIEPER PISTOL

I have a small pistol that says Anc. Etabl. Pieper Herstal Belgium. Do you know where I

can find out anything about this pistol?

Thanks, Jim.

Ancien

Etablissments Pieper was among the rare Belgian firearms producers daring to stamp a trade

mark on their products. Another trade-mark of A.E.P. was "Bayard". There were

three small-sized Bayard pistols (including a vest-pocket sized one, shooting .380 Auto/ 9

x 17 mm Browning cartridges) and one different model, shooting .25 ACP (6.35 mm Browning)

ammo. This little gem is presumably in your possession. The grip panels of it bears a

little oval with logo "HP" from trade-mark Henry Pieper (1840 - 1898. He

established the firm to Herstal, Liége, Belgium in 1866). Pistol was designed in 1907 by

Bernard Clarus. It has a tip-down barrel assembly, looking like figure "8" when

seen from the business end.

Bore is lower, tunnel for the recoil spring is above it just like in the F.N. Browning

pistol Model 1900, but the slide doesn't cover the barrel. According to Ian V. Hogg:

"The Pieper automatic pistol was a unique design with a tip-down barrel unit; the

recoil spring was contained in a tunnel above the barrel and connected to the breech block

by a hook which engaged automatically as the barrel was tipped up into the firing

position. The details of construction varied between models as improvements were

incorporated, but the basic design remained the same. This form of construction led to an

unusually slender pistol and it was a commercial success until the late 1920s.

The demise of design is understood to have been due to high cost of manufacture in the

face of cheaper competition. The patent was licensed to the Austrian Steyr factory and

produced there until shortly before the Second World War".

Pistols like Pieper and Steyr-made copy of it needs no extractor for spent cases at all.

Remaining chamber pressure carry out extraction and ejection of the empty shell. Tip-down

barrel unit is needed only for extraction (or actually dropping away) a misfired cartridge

or removal of the cartridge from chamber without need to remove filled magazine from the

pistol. Some small Beretta and Taurus pistols have similar construction but simplified

recoil spring arrangement and an exposed hammer for de-/re-cocking or double-action-only

firing mechanism.

As mentioned above, your cute little pistol is some variant of the Clarus-Pieper Model

1907; a rarity, when compared to huge production output of .25 ACP caliber F.N./ Browning

pistols.

1602 MMII; PT.

"KUDOS" AND RELOADING COMPONENTS

Hello Pete!

Very happy to read your most recent updates to GOW site: it is a marvelous resource, and I

hope some of the viewers I have pointed to the site have paid their debt of honor.

Re: "Word "kudos" means "tissue/ weave/ texture" in Finnish.

"Thank you" is: "kiitos/ kiitokset/ kiitoksia"." The word

"kudos" as used here in the 'States is similar in meaning to "acclaim"

or "applause," or perhaps best "commendation:" I believe it is of

ancient Greek derivation, so not based on the uncommon language group Finnish belongs

to...

Re: "On the more than sixteen years old book "CARTRIDGES OF THE WORLD 5th

EDITITON" by FRANK C. BARNES is a grim prophecy that: ".303 Savage ... is

rapidly becoming obsolete". Your friend should start handloading of the cartridges,

if the .303 Savage cases are still available..." and "Hello, I happened upon

your site quite by accident. It's excellent! Question. I have a quantity 20 x 110 mm

Hispano cases all new but they are Berdan configured. I cannot find a supplier of these

primers..."

Here in the U.S. (actually based in California, fertile ground for the communist gun

banners, of all places!) is a company called "Old Western Scrounger," that

specializes in obsolete ammo and reloading components for them as well as Berdan

cartridges. He may have the components required by these people. Website url is: http://www.ows-ammunition.com/

Take care, and thank you for all your wonderful work on G.O.W.!

Bruce, CA

Comments.

Finnish word "kiitos" (noun/ substantive) may be translated to English as

"acclaim" or "commendation". This very word was presumably coined by

"father of Finnish literary language", bishop Mikael Agricola (1494 - 1557), who

translated many chapters of Holy Bible to Finnish from Latin - and Creek!

"Kiitos" is therefore with all probability derivation from ancient Creek word

"kudos". It is entirely different from Swedish "tack", German

"Danke" or Russian "spasibo/ blagodaryo".

Many thanks for the website address of O.W.S. The term "Kalifornian

Kansantasavalta"/ "People's Republic of California" has been known even in

Finland since mid-1990s. Administration of your home state seems to be considered equal to

that of Cuba or North-Korea.

1702 MMII; PT.

VALMET/TIKKA/FENNEWERK etc SHOTGUNS

Came across your site by accident in doing a web search regarding the status of

Valmet/Tikka, etc.. I was hoping you might be able to shed some insight on what's what

with the current production of shotguns made like the original Remington 32/3200 style. I

currently own a couple of 412T Valmets and was interested to find that some gun dealers in

the US are importing and selling "Fennewerk" 412 S in a variety of

configurations (ie: O/U shotguns, combo's and O/U rifles).

They are supposed to be identical to the Finnish made Valmets. I've also seen in a local

gun shop a Tikka 412s imported into the US by Stoeger that was made in Italy. Can you sort

out the mess? I did read a little that you wrote regarding how Sako bought Valmet, was

bought out by Beretta and now I was wondering what was happening. Any idea?

Thanks for your time. Harvey

Over-under

TIKKA guns were absent from the catalog of SAKO, published after SAKO-BERETTA fusion and

there were a large selection of Beretta guns on this SAKO KUVASTO, but on the most recent

(?) catalog exists weapon-system TIKKA 512 SD with a warranty that the barrels are fit for

actions of VALMET 412, TIKKA 412 and TIKKA 512 S. Beretta guns does not exist at all.

There is not a year of printing mentioned on the Sako catalogs: I don't know, how old is

my "most recent" Sako Tuotekuvasto, but you can (I cannot) visit on the website

www.sako.fi and look the selection. It is, however, rumored that Sako website is updated

just once bi-annually.

I have no direct or even indirect contact with SAKO Oy. Therefore I am unable to sort out

the mess. The TIKKA over-under guns are really made in Italy. Already in mid- or late

1980s were action forgings (or investment casts) bought from Italy and just machined &

finished by VALMET Tourula Works. Trade-mark FENNEWERK is unknown to me, but I am ignorant

about modern firearms business in general.

1802 MMII; PT.

DISASSEBLY OF BURGESS SHOTGUN

I saw you had an article in

Finnish on the Burgess. I need the disassembly on this gun. Do you know where i can

find this? Do you have the article translated into English?

I saw you had an article in

Finnish on the Burgess. I need the disassembly on this gun. Do you know where i can

find this? Do you have the article translated into English?

Thanks, Ken, Canada

Source

of my article was a book "WORLD'S FIGHTING SHOTGUNS" by THOMAS F. SWEARENGEN,

(C) 1978. There is not information about disassembly/re-assembly of Burgess gun on this

book, and I have not seen any other printed source about Burgess shotguns - even the

hunting versions. One friend of us has patent drawings of many U.S. Patents granted to

inventor ANDREW BURGESS, but I afraid that the drawings does not help you to disassemble

the gun and put the mechanism together again.

The most probable country where one can meet a Burgess Police Gun is Canada. Guns of New

York State's Penal System (about a hundred pieces) were exported to Canada and sold there

by a public auction in 1920. I hope that some Canadian visitor has user's manual or

maintenance manual of Folding Gun. Copies of it's pages containing directions for

disassebly/ assebly are welcome to us. One Police Gun is also in the rack of a Finnish

firearms collector, but I don't know whether the maintenance manual of it is still left.

1802 MMII; PT.

Comment of a visitor

IT MAY BE A MONDRAGON RIFLE!

In your part 16 article, "Jose" was inquiring about an

old rifle that was marked "Fab. D'Arms Neuhausen". From the description

provided, it is almost assuredly a Model 1894 "Mondragon" rifle. This

rifle and ammunition was a joint venture between Col. Rubin of the Swiss munition factory

at Thun and Mexican General Manuel Mondragon.

The rifle cartridge used in Jose's rifle is probably a 5.2 x 68 mm. This round used a

rimless case and known examples were either made by Polte of Magdeburg, Germany or by the

Swiss federal factory at Thun. I believe the goal was to develop a very high velocity

cartridge. At least eight known varients of this cartridge are known with least six of

them using an internal "piston" to accelerate the bullet's flight.

These rifles were strictly experimental and several variants exist. It would be

interesting to obtain more information from Jose on his rifle so as to narrow down when it

was constructed in the timeline of this experimentation.

There is an article on this rifle as well as other ordnance developed by Mondragon written

by Hans Tanner in "Guns of the World" (circa 1977). If you need any further

information on this firearm or ammunition, please let me know.

David, Oregon, USA

Comment of PT.

You may be right, although those experimental 5.2 x 68 mm Mondragon rifles are very rare.

Unfortunately I don't know, whether Jose lives in Mexico, where those rifles may be met

(by a very good luck). "Mea culpa" that the French factory stamp didn't alert

me. Usual factory logo of Neuhausen was: "S.I.G." (German. Abbreviation from

"Schweizerische Industrie Gesellschaft"). General Manuel Mondragon was

a Mexican Military Attaché in Paris, France, and the rifles of his design were stamped

therefore with French logo: "Fab. D'Armes Neuhausen".

All of them were not autoloaders like Mondragon rifles Model 1908, caliber 7 x 57 mm, but

the action was a straight-pull bolt action with a "fire selector". When it was

set to the "rapid fire" position, it was possible to shoot non-aimed fire about

one shot per second without touch of the trigger, just by reciprocate "pumping"

of the bolt. The rifle went off immediately after the feed of fresh cartridge and closing

of the rotating bolt. General Manuel Mondragon became soon aware of inaccuracy and hazards

of "pump firing". So he designed a series of self-loading rifles since 1893,

based on the gas cylinder/ piston action.

Patent drawing of 7 x 57 mm Mondragon rifle. There were as many as

seven locking lugs on the breech-bolt and the gas piston was hermetically sealed into the

gas cylinder by copper sealing rings, like piston of a steam or internal combustion

engines. Without a proper lubrication this piston/cylinder combination gave irregular

loading cycles and high vertical spread of hits, according to the Germans who used

Mondragon rifles as weaponry of reconnaissance and fighter aeroplanes during 1st World

War, until adoptment of synchronized Maxim machine guns for their Fokker planes.

Manually fed "micro caliber" Mondragon rifles are extremely rare collector's

items, and so are also cartridges of them, designed by E. Rubin, contemporary director of

Swiss Military Laboratory of Thun (a noted co-designer but not inventor of the

metal-jacketed rifle bullet). Contemporary Swiss smokeless rifle powders had not yet any

deterrent surface coating in 1894. Therefore it was needed to reduce the chamber pressure

of cartridges with a cardboard wadding or "collar" around the bullet base.

Germans were discovered use of deterrent coating on the flake powder kernels by paraffine

wax "moist-proofing surface" in 1890. The coated powders made complicate and

expensive arrangements, like bullet collars, unnecessary before or soon after the end of

19th century.

The first lot of Mondragon self-loader rifles (50