Gunwriters' Front

Page Suomenkielinen Gunwriters

Link page Part 1

Part 3

ARCANE, or Forbidden Knowledge about Handloading

Part Two: General and exclusive data

By: P. T. Kekkonen (1999)

Continued from Part 1

"What means that international word: ARCANE ? It sounds

like Latin !" > Jess, dear fellow Hard-Core Handloader ! Word

"ARCANUM" is Latin meaning a secret potion or drug with the elements kept

secret, but also The Philosophers' Stone of medieval alchemists believed to yield gold

from some less-rare metals, usually from lead. Name for the article was selected because

since early 1980's many authorities of handloading wished the author to keep all his

knowledge on reduced-charge loading as a well-concealed secrecy.

When the first part of story Arcane was still under creation process, one fellow-gunwriter

made some test-shooting with "Kissan aivastus" (id est: "Cat's

Sneeze") loads. He has not 7.62 mm Mosin-Nagant rifle or carbine, but a Mauser model

98 k, re-barreled for the .308 Win. a.k.a. 7.62 mm NATO cartridges. He had resized and

re-primed LAPUA cases with REMINGTON 9 ½ Large Rifle Standard primers. He made his

substitute No.1 Buck-sized spherical bullets from spent .22 LR solid bullets, weight 40

grains. This is THE way to get No.1 buckshots in Finland. He sealed those lead pills into

the case necks with a small dose of vaseline (mineral jelly). Despite of his home-made

bullets, and lack of optical sight, the accuracy of shooting was very satisfactory to ten

meters, but less than fair to 30 meters range, just as the accuracy of

"primer-only" loads was ca.70 years ago.

This old discovery seems to be functioning! When the friend of the author shall get

factory-made buckshots, he'll try shooting with more efficient primers (FEDERAL 215) and

the "booster charge" of powder, VIHTAVUORI N 310 or HODGDON HP-38, also

chronographing bullet velocities. Interesting notice was that resized cases didn't leak

gasses back. The soft vaseline sealed an outer wall of the case neck too ! This is a very

important notice for those riflemen, having not the cases previously shot with their own

rifle, but just salvaged brass with live primers, or cases picked up from a shooting

range, resized down to the factory-made cartridge's dimensions, and reprimed.

Still some hints from the history

Who was the inventor of Cat's Sneeze ? > The author is innocent, but one Mr. VELI

NIEMINEN, then a Secretary of the Finnish Shooters' Association, is the most suspected. In

his "Handbook For The Shooter", published in 1926, he was not yet mentioned use

of bore-sized lead pill as a projectile for gallery-load of 7.62 mm military rifles,

because Mr. Nieminen was a "zealot", who insisted on adoption of the 7 x 57 mm

Mauser as a military rifle and machine gun caliber in Finland. But he was an enthusiastic

researcher of match-grade rifle loads and special loads, until his death in 1936. In his

handbook told Nieminen many stories of "schuetzen shooting" with cast lead

bullets, loaded into cases almost without tools or dies - except those needed for

decapping and re-priming.

"Immortal" lubricated shells

Brass cases were not lathe-turned "everlasting

cases", like those shells used by many schuetzen shooters in the USA a century ago.

Common 8.15 x 46 R brass shells were coated with beeswax or tallow - or a mixture of them

(usual bullet lubricant). Wax or lube prevented the permanent deformation of case metal.

Resizing of shells was needless procedure, because the primer pocket became useless before

the case itself expanded too "fat" to fit into chamber or keep the bullet

properly in the case neck.

Brass cases were not lathe-turned "everlasting

cases", like those shells used by many schuetzen shooters in the USA a century ago.

Common 8.15 x 46 R brass shells were coated with beeswax or tallow - or a mixture of them

(usual bullet lubricant). Wax or lube prevented the permanent deformation of case metal.

Resizing of shells was needless procedure, because the primer pocket became useless before

the case itself expanded too "fat" to fit into chamber or keep the bullet

properly in the case neck.

Some stubborn shells withstood hundreds of

reloadings and shots. The VERY most durable cases lasted more than a thousand loads and

discharges, despite of their BERDAN primer pocket with an integral anvil, which became

easily damaged by careless decapping with a pick or chisel. Water-pressure was a more

gentle way of depriming, and it was essential to remove powder and primer residues from

inside and outside of shells after the day's shooting. Veli Nieminen emphasized also a

necessity to wash the tallow , or a lube mixed with tallow, away from the brass cases,

because it may turn the brass green and brittle. Beeswax or mineral lubes had no ill

effects.

Some stubborn shells withstood hundreds of

reloadings and shots. The VERY most durable cases lasted more than a thousand loads and

discharges, despite of their BERDAN primer pocket with an integral anvil, which became

easily damaged by careless decapping with a pick or chisel. Water-pressure was a more

gentle way of depriming, and it was essential to remove powder and primer residues from

inside and outside of shells after the day's shooting. Veli Nieminen emphasized also a

necessity to wash the tallow , or a lube mixed with tallow, away from the brass cases,

because it may turn the brass green and brittle. Beeswax or mineral lubes had no ill

effects.

Activists loaded low-pressure cartridges

Handloading of low-signature rifle cartridges has been "a doubtful bustle" in

Finland since the very first years of 20th century. Amongst the first pioneers of

special-purpose handloading was the very most valiant National Hero of Finland, EUGEN

SCHAUMAN, who executed detestable Russian governor-general NIKOLAY BOBRIKOV with an

explosive (mercury-filled ?) bullet from his BROWNING pistol model 1900, and committed a

suicide with next two shots, in the June 1904. Schauman died instantly. Bobrikov

languished many long hours, moaning in Russian: "Pochemu..? Pochemu..?"

("Why..? Why..?").

Before his death Eugen Schauman was a member of the ACTIVISTS, a troop of daring Finns who

planned to release Finland from the Imperium of Russia - by fighting with firearms, if

necessary. There were obtained (in 1902) some Swedish 6.5 x 55 mm MAUSER/-96 rifles and

(as early as in 1899) the WINCHESTER Model 1894 hunting rifles of caliber .25-35 WCF, for

elementary training of the riflemanship and maintaining of the marksmanship by the regular

target practice, but also for elimination of the most detestable Russian officials in

Finland -- and their Finnish collaborators -- of course. As high-ranking Russian's

sycophant as an Attorney General, ELIEL SOISALON-SOININEN was executed, along with some

police chiefs, but all of them were eliminated with handguns. These capital punishments

were executed after death of N. Bobrikov and Eugen Schauman.

Gun Control - creation of a dictatorship !

Governor-general Bobrikov was fully authorized

dictator in Finland since 1903. Among his very first dictations was "A Gracious Act

On The Registration And License-compulsion Of The Rifled Fire-arms". Those

compulsions were applied to rifled shoulder arms only, including the "gallery

rifles", chambered for .22 BB Caps or similar pipsqueaks, known as FLOBERT rounds.

Shotguns and handguns were free from registration or license-compulsion. Then-modern

military rifles, like Swedish Mauser, were especially risky to possess and use on the

outdoor shooting ranges.

Governor-general Bobrikov was fully authorized

dictator in Finland since 1903. Among his very first dictations was "A Gracious Act

On The Registration And License-compulsion Of The Rifled Fire-arms". Those

compulsions were applied to rifled shoulder arms only, including the "gallery

rifles", chambered for .22 BB Caps or similar pipsqueaks, known as FLOBERT rounds.

Shotguns and handguns were free from registration or license-compulsion. Then-modern

military rifles, like Swedish Mauser, were especially risky to possess and use on the

outdoor shooting ranges.

Left: Portrait of Governor-general Bobrikov.

Noise of the target practice became a problem. There were some models of the suppressors invented in 1903, but they were not yet produced, except a bulky "sound deadening device" of W.W. GREENER's "Humane Cattle-Killer"; a slaughtering tool. Logical solution was handloading of "silent without silencer" cartridges. Eugen Schauman developed them, or at least he gave information about low-noise loads with lead bullets and the "blue powder" by his letters to the activists all-round the Finland.

Right: Eugen Schauman, a Finnish Independence Activist.

Right: Eugen Schauman, a Finnish Independence Activist.

Lost correspondence

Most of those letters are lost forever. They were "too hot material" to possess

after the heroic deed and death of Eugen Schauman. Russian "OKHRANA" (the Secret

Police; predecessor of KGB) did not believe fully on the claim: "I committed my deed

alone, without any conspiration behind me..." A letter, including this statement --

addressed to the emperor of Russia -- was found from the pocket of deceased Schauman. This

letter contained many answers to the question: "Pochemu ?", but the Czar of

Russia never read it...

The forgotten Deputy Executioner

An other National Hero of Finland, an university student LENNART HOHENTHAL, was made all

the necessary preparations for a physical elimination of Bobrikov. He was hired a room

with an un-obstacled view to the route from Bobrikov's residence to the governor-general's

office. Hohenthal was equipped with a rifle and some handloaded cartridges -- presumably

charged with a small dose of the "bluepowder" and a lead bullet. Lennart

Hohenthal planned to escape after his deed, without an intention of the "Kamikaze

assault". Therefore he was forced to avoid an alarming noise of his planned fatal

shots.

Eugen Schauman had, however, a more suitable official

position - as an accountant in the Board of Schools. He could meet Bobrikov in a staircase

of the Senate House..! Distance of his pistol shots was less than three meters..! Deputy

executioner L. Hohenthal eliminated somewhat later the Finnish General Procurator (i.e.

Attorney General), a traitor Eliel Soisalon-Soininen -- but with a handgun. He was caught

by Okhrana, but escaped with assistance of some other activists. He exiled to Sweden and

died there after a long unnoticed life - not so many decades ago - as a forgotten and

almost unknown Finnish freedom fighter: "SIC TRANSIT GLORIA MUNDI !"

Eugen Schauman had, however, a more suitable official

position - as an accountant in the Board of Schools. He could meet Bobrikov in a staircase

of the Senate House..! Distance of his pistol shots was less than three meters..! Deputy

executioner L. Hohenthal eliminated somewhat later the Finnish General Procurator (i.e.

Attorney General), a traitor Eliel Soisalon-Soininen -- but with a handgun. He was caught

by Okhrana, but escaped with assistance of some other activists. He exiled to Sweden and

died there after a long unnoticed life - not so many decades ago - as a forgotten and

almost unknown Finnish freedom fighter: "SIC TRANSIT GLORIA MUNDI !"

Although this painting "Attack" by Eetu Isto had to be kept secret, independence activists were shown it to arouse their spirit. The artist has painted the Finnish Maiden as trying to protect the book "LEX", laws of Finland from being torn by the twin-headed Eagle of Imperial Russia. The original painting was sought to be destroyed by Russian authorities without success. Now it is kept in the National Museum of Finland.

Lost handloading data

Just one letter, written by Eugen Schauman to one Communal Health Officer in rural

Finland, has escaped confiscations of the Okhrana, or destruction by timid addressees. The

physicians and drug-store owners were very important advisers to the handloaders in 1903,

because they had the very best scales or "balances" for weighing of the powder

charges to the precise search of an optimum reloading combination for each individual

rifle, and for indented purpose. With a balance was weighed the volume of each

handloader's set of the powder dippers.

There were four different kinds of powder in use: The black powder, a

"bluepowder", the "smoke-lacking powder" and a "strong(ly)

smoke-lacking powder", according to the nomenclature of Eugen Schauman. The letter

was written in Swedish, which was a common language of educated Finns in 1903. Technical

vocabulary of Swedish was undeveloped, because smokeless and semi-smokeless powders were

novelties in the remote countries, as well as the art of rifle cartridges' reloading with

those propellants.

The letter (almost) lacks reloading data, because Schauman was delivered it earlier to the

addressee in a parcel, containing a rifle, selection of the bullets and a hundred grams of

bluepowder. Weights of the bullets are, unfortunately, not mentioned on the letter, dated

in March 12th 1903 and addressed to Doctor A.J. WAREN, Esq., of Orimattila. But the

bluepowder was a very strong medicine, and the dosage of it was found necessary to repeat.

"Just what the Doctor orders..."

Doctor Warén was inquired Schauman the loading data for a Swedish 6.5 mm Mauser cartridge

for the rifle, previously delivered to him. Eugen Schauman was able to give him reloading

hints "from the mouse up to the moose", or from the mildest back-yard practice

load up to the full-power charge with the strong smokeless powder.

" -- For the shooting to 20 - 30 meters distance you may load cartridges with 0.20

gram of bluepowder and a spherical bullet of the hardened lead alloy."

"-- For the shooting to 100 - 150 meters, the cartridge loaded with 0.3 gram of

bluepowder, along with a long lead-alloy bullet."

"-- To the long-range shooting, up to 400 meters, the cartridge loaded with the

smoke-lacking powder along with nickel-jacketed bullet and to still more extended ranges

the cartridges loaded with strong(ly) smoke-lacking powder, along with a long

nickel-jacketed bullet."

Doctor had the sample bullets and powders, presumably in original boxes and cans. Almost a

century later it is very hard to guess right at the "Doc's orders" to his

fellow-activists.

Something blue

Mysterious "bluepowder" was some kind of a then-common BULK SHOTGUN POWDER. This

is still today THE propellant for reduced-charge rifle cartridges, from the .22 Hornet to

14.5 mm Russian or even the 20 mm anti-tank rifle ammo. (That 14.5 mm -- or ca. caliber

.60 -- is, however, the biggest practical caliber for silenced firearms with an usual

caliber-sized bullet. More "fat" projectiles are too noisy in the flight, even

when flying at less than the Mach 0.9 velocity. The fléches = arrow projectiles, or

tubular bullets, may extend the maximum caliber of silenced firearms up to the shotgun

gauge 10, or 20 millimeters).

Those bulk powders are no more in production, despite of the demand. American bulk powders

were usually made by tearing the bone fiber, compressed from the nitrated cotton, to the

small kernels. They were rolled in the rotating drum, making so the tiny

"dust-balls", impregnated with a saturated solution of inorganic oxidizing salts

-- usually with potassium and barium nitrate -- and dried.

Then those little kernels were moistened with HOFFMANN's DROPS (ether-alcohol mixture), or

acetone or aceditin, and rolled in the "candy drum" until surface of the kernels

was dry, smooth and hard. They were actually coated with a nitrocellulose lacquer. Before

impregnation or after this surface gelatinizing, it was possible to dye the powder kernels

with very bright aniline dyes.

Making of the "hottest" powder

An optimum propellant for the rifle "gallery loads", the renowned "E.C.

BLANK POWDER" -- mentioned in ARCANE Part 1. -- was made by similar process, but with

a very slight percentage of salts and usually without kernel surface gelatinization at

all. Gun-cotton fibers were interlaced with a dilute gum-Arabic solution in the

"candy drumming" stage of the manufacturing process.

An unwritten textbook

Unfortunately there is unavailable "A COMPLETE BOOK OF THE POWDERS"! So it is

impossible to tell the trade-mark or manufacturer of the bluepowder. It was definitively

not the German blank cartridge powder (bright yellow) and presumably not the grass-green

Belgian "EMERALD".

American DuPONT's "SCHULTZ SHOTGUN" powder was popular in Finland many years

after the end of its production in 1926. It was used for forest-bird hunting with 7.62 mm

MOSIN-NAGANT rifles, loaded with 7.65 mm Luger bullet or a shortened rifle bullet,

weighing 6 grams. Powder charge was one gram or slightly more. Cartridge case was more

than half-full, because the bulk powders were "bulky"; id est: Weight of them

was light when compared to the volume of a charge. The charges were rather bulky, when

compared with modern handgun powders, because of the low calorimetric energy of bulk

powders.

The original Dram Equivalence

Semi-smokeless bulk powders were developed for reloading of the shells to the old

shotguns, which were never proofed for shooting with smokeless powders. Shotshells were

charged by the old -- but still valid -- rule of thumb: Equal volumes of the black powder,

bird shots and the wadding. ("Third-third-third" rule).

Earliest bulk powders, like an original "42 Grains SCHULTZ" in 1864, were

developed to give an equal muzzle velocity and the chamber pressure, compared with equal

volume of the "shotgun grade" black powder. Actual weight of the semi-smokeless

powder did not matter. A vast majority of handloaders had never seen the more accurate

balance than a steelyard of a butcher or fishmonger.

Charge weights were compared with a volume of a dipper, holding three Avoirdupois drams of

CURTIS & HARVEY Nr. 6 black powder (with a very uniform density). Three drams equals

82 grains Avdps. or 5.13 grams. The same volume of original "Sawdust Schultz"

weighed 42 grains or 2.72 grams.

"Gone are the days..!"

There were also still less dense bulk powders in the turn of 20th century, like

"SMOKELESS DIAMOND" or "E.C. No. 3" with a weight 33 grains, and

"AMBERITE" with the weight 28 grains per three drams dipper's volume. (In modern

readings had "28 grains bulk powder" the weight-per-volume ratio 9 grains or

0.58 gram per CC). Some most modern powders, like HODGDON "CLAYS/UNIVERSAL", are

truly light in weight-per-volume ratio: 0.45 gram per CC, or approximately so..! That is

ca. seven grains per CC, or according to the old reading is the Universal powder a

"twenty-two grains powder", but PLEASE, NOTE: Do not think ANY of modern

smokeless general-purpose powder to be as an old bulk powder ! They may be three or four

times as powerful as were the propellants of "Good Old Days"..! Those days are

gone...forever ?

WANTED: Information !

The author has not yet all the needed information re DuPont "SCHULTZ SHOTGUN"

powder, which was manufactured between 1900 and 1926, mostly for the reloading of

shotshells with "bulk-by-bulk" dosage, using a black powder dipper for the

distribution. That powder was also recommended for "the light gallery charges in

metallic cases." (Recommended by the MANUFACTURER ?? >Jess ! In the FIRST quarter

of the 20th century..!)

Powder kernels were irregular in size and shape. Such were most of bulk powders, known in

Finland as the Old-fashioned Corned Powders. Who can, and is willing, to tell the COLOR of

powder kernels and the DENSITY of this propellant ? It is presumably printed on the powder

canister label as: "XX grains (bulk) powder." Some blank lines of Finnish

history may become printed by this information.

Lead bullets were plentily available

In 1903 were the lead-alloy bullets available for each & every rifle cartridge, save

the most wildest "wildcats". Jacketed bullets were new and unusual projectiles

in Finland. Still, in early 1930's, more than 30 years after the date of Eugen Schauman's

letter to Dr. Warén, a German "WAFFEN UND MUNITION"/"ARMS AND

AMMUNITION" catalog listed more than thirty cast lead-alloy bullets for handloaders

of the rifle cartridges, in several calibers from .22 to .45.

There were also spherical lead buckshots and

air-rifle pellets listed for loaders of the "gallery practice" rifle cartridges.

Air-gun pellets were not yet of a frail Diabolo-design, but the neat conical-pointed

Minié-shaped slugs in several calibers up to 6.5 mm. Two kinds of lubrication-grooved

cast bullets for Swedish 6.5 mm Mauser rifle were listed on the W.u.M-catalog: A

round-pointed slug, weighing 4.15 grams, and a flat-nosed bullet; weight 4.30 grams.

There were also spherical lead buckshots and

air-rifle pellets listed for loaders of the "gallery practice" rifle cartridges.

Air-gun pellets were not yet of a frail Diabolo-design, but the neat conical-pointed

Minié-shaped slugs in several calibers up to 6.5 mm. Two kinds of lubrication-grooved

cast bullets for Swedish 6.5 mm Mauser rifle were listed on the W.u.M-catalog: A

round-pointed slug, weighing 4.15 grams, and a flat-nosed bullet; weight 4.30 grams.

("Imperial" weights were 64 grains and 66.4 grains). Bullet diameter was 6.72 mm

and the price 53:57 US-$ per a hundred... kilograms ! Not so high price, because there

were almost 24100 round-pointed bullets in the delivery crate, net weight 100 kilograms.

In the very same year 1934 was the possession of a firearm's silencer rated at $ 200:00 by

a strict provision, "LEX MORGENTHAU" -- a.k.a. Federal Firearms Act -- in the

United States of America.

"Not for the jacketed bullet !" (?)

The author thinks by his experience (just like Eugen Schauman thought in his time) that a

lubricated slippery lead-alloy bullet is THE projectile for reduced-charge rifle loads;

especially for the subsonic cartridges. Schauman warned, however, in his letter 12th Mar.

1903 Dr. Warén against use of the bluepowder as a propellant of ANY jacketed bullet in a

6.5 mm Mauser rifle. This warning was presumably involuntary exaggeration; based on the

lack of an empirical knowledge.

The lead-alloy bullets were available. So, why run a risk..?! There were three kinds of

jacketed bullets for use of Dr. Warén in 1903. Two of them were presumably with

cupro-nickel plated steel jackets with weights 9.0 grams and 10.1 grams. These bullets

with a nominal diameter 6.70 mm were exclusively indented for 6.5 mm Swedish Mauser m/-96

military loads.

An expanding bullet

The third projectile, with a thin cupro-nickel jacket, was actually made for .25-35

Winchester cartridges, but according tho Eugen Schauman it was "successfully used for

shooting up to 300 meters range. One advantage of these bullets is the low price (FIM 3:25

per 100 ) and the jacket metal is softer than that of Mauser bullets. They shall wear the

rifle less (than military projectiles).Along with these bullets is used the strong

smokeless powder. Please, note: Caliber of these bullets is somewhat smaller than that of

Mauser bullets".

Nominal diameter of .25-35 WCF bullets is .257" or 6.53 mm, or just a little more

than the bore diameter of Swedish Mauser. A heavy charge of strong (Swedish

"BALLISTITE" ?) rifle powder could, however, expand the soft-jacketed bullet to

become groove-filling. Price of those bullets was truly low. One US-dollar equaled 5:18

Finnish marks in 1903. A hundred bullets cost less than 63 cents...

A bullet for reduced loads ?

Presumably not for the mildest reduced-charge loads, for those subsonics loaded with a 0.2

to 0.3 gram of the bluepowder. Chamber pressure was too low for an expansion of the

bore-sized projectile. A doubled charge, 0.6 gram or slightly more could do the job,

making the noise of shots not yet too alarming in the rural districts. But the author must

repeat once again: There WERE lead-alloy bullets available in 1903. (In 1999 they ARE

unavailable for the rifle cartridges in Finland. Plentily yielded! > Jess, but for the

handguns only..! Not for the very most common rifle calibers .308 or 7.62 mm).

Economy of the handloads

The cartridges loaded with a mere 300 milligrams of the bluepowder and lead-alloy bullets

were economy in use: "The shells are possible to reload almost times without

number", according to Eugen Schauman. From the view of businessmen, it is not

just an illusion, but a nightmare that too many riflemen shall buy twenty cartridges along

with a rifle and reload the cartridges into their shells "the times without

number", with 0.2 to 0.5 gram charges of the "hot" powder -- and just for

some very special purposes with some "official" tenfold (3 to 5 grams weighing)

charges of the rifle powder, according to the

loading data found from reloading manuals or handbooks.

Some moderate loads for .308 Winchester

"Again and still again the lecture on Finnish history

!! We have not persons like a governor-general Bobrikov ! All we need is the reloading

data !!"

>Dear fellow Hard-Core Handloader! There is an old Finnish proverb: "KUKA EI

MENNYTTÄ MUISTA, HÄN EI UUTTAKAAN YMMÄRRÄ !" (= "One, who is unable to

recall the past, can never understand the novelties"..!) All the essentials of

reduced-charge handloading are printed on the yellowed pages of the OLD books and the OLD

periodical magazines..! Each country has also hundreds of Bobrikov's and thousands of

their sycophants, but never too many Schauman's or Hohenthals..!

The author found an old Finnish "ERÄ"

magazine, issued in the November 1982, containing an article and reloading data on the

mild loads for a popular .308 Winchester a.k.a. 7.62 x 51 mm NATO cartridge. Loads were

tested by the author in March 1981. So the copyright of this data belongs to the author,

but the knowledge belongs to each and every handloader "on the Web".

The author found an old Finnish "ERÄ"

magazine, issued in the November 1982, containing an article and reloading data on the

mild loads for a popular .308 Winchester a.k.a. 7.62 x 51 mm NATO cartridge. Loads were

tested by the author in March 1981. So the copyright of this data belongs to the author,

but the knowledge belongs to each and every handloader "on the Web".

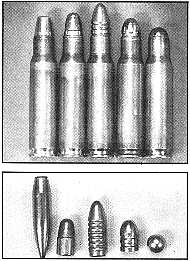

Some .308 Winchester test cartridges an buckets. From left to right: Reversed 190 grains HPBT, SPEER "PLINKER" (very accurate for .308 subsonics), IDEAL/LYMAN cast No. 311 466, LEE 311-93-1R (the author's "pet slug" for .308 AND .32 ACP pistol cartridge), HAENDLER & NATERMANN's 8 mm lead spherical.

Test rifle was a STEYR SSG with a composite stock. Cartridge cases were made by LAPUA;

once shot in Steyr and partially neck-resized with LEE LOADER reloading kit's die. Just

the 4.5 mm (.17") length of the case neck behind its mouth was resized, because the

author is reluctant to stress the shells more than it is essential.

Primers were VIHTAVUORI Nr. 28's. (No more available! Any Boxer Large Rifle Standard

primer is similar enough to substitute Nr. 28). The LR Magnum rifle primers are

recommended for the mildest subsonic loads, but some authorities have recommended use of

the Large Pistol Standard primers for the necked rimless shells, especially if the

shoulder angle of the case is less than 20 degrees. (That of a .308 Win. shell is even 20

degrees-of-angle). It seems to be that the actual power of primers is less important, but

a consistent power, along with an uniform hardness of the primer cap's metal, is at least

significant.

The powder used for test-shootings was VIHTAVUORI's N 320, a general purpose propellant,

"officially recommended" for handgun or shotshell (re)loads, but it is about

similar to the German "Sorte 33 Platzpatronen Nitrozellulose Rohrpulver"

(tubular-kernel single-base blank cartridge powder, adopted in 1933). It was used for

loading of top-quality subsonic FINOWER INDUSTRIE 7.9 x 57 mm JS "Nahpatronen"

and also for the "½-charge target practice loads" for 7.9 x 92 mm ultra-high

velocity anti-tank cartridges No. 318.

Calorimetric energy and the burning rate are slightly lower than those of VIHTAVUORI

N 310, due to the bigger kernel size of N 320 and a slightly different potassium

nitrate percentage. Due to the broad safety margin of these loads tested in 1981, it is

safe to load powder N 310 by the use of loading data for N 320. Available bullet

velocities shall become somewhat higher with the equal charges of N 310, but suggested

minimum charges may be slightly reduced. The author will emphasize his word: SLIGHTLY !!

One friend and colleague of an author, a highly educated Finnish gunwriter, did not

believe on warnings that the Secondary Explosion Effect (S.E.E. -- also known as the

Reduced-Charge Detonation) is possible with sub-minimum charges as small as 0.2 grams =

200 milligrams = 3.1 grains with a force, able to wreck a good quality .308 Winchester

rifle. One full gram of the very same powder behind the same kind of bullet may be

completely safe charge. The friend almost lost his eyesight, despite of the safety goggles

he bore.

Test-shots with LAPUA D-46 bullets, weight 11.0 grams, dia. 7.83 mm, seated point

backwards into the cartridges with overall length 61 mm, gave velocities as follows:

Charge 0.5 gram Charge 1.0 gram

281.5 m/s

539.7 m/s

average

250.0

532.0 lowest

313.0

546.0 highest

Notes: Charge ½ gram gave subsonic velocity (avg.) but also some transsonic bullet

speeds. This charge is less than suggested minimum and not recommended because of the

great velocity variation. A doubled charge, one full gram, gave tolerable uniformity of

velocities. Chamber pressure was similar tho that of factory loads. Due to the special

arrangement of the chronograph "Sky Screens" of OEHLER Model 12, these listed

velocities are about the muzzle-speeds of bullets.(The friend, who was loaded 0.2 gram of

N 320 behind D-46 bullet, courted a SEVERE disaster !! He developed, of course, his

"Mouse Load" contrary to the published data and in the defiance of S.E.E. - the

detonation).

The cast bullets LYMAN Nr. 311 466 of wheel weight alloy, resized to the dia. 7.92 mm,

actual wt. avg. 9.96 grams, shot without a gas check, gave velocities:

Charge 0.4 gram Charge 0.5 gram Charge 1.0

gram

327.8

379.1

536.8 avg

310.2

374.8

533.0 lo

333.3

383.2

542.2 hi

Notes: Cartridge o.a. length was 65.5 mm. This bullet is designed for the long-necked

cases of military rifles with a "long leade" or "free-bored forcing

cone" (like .30-40 KRAG or .30-06). It was resized for use in Mosin-Nagant m/1891

rifle. Non-recommended bullet design for .308 Win., but included for the comparison.

Charge may be still more reduced (down to ca. 0.35 gram). A maximum charge leaded the bore

badly because of the lack of gas check. Author scraped the lead-fouling away by shooting

of some SPEER "PLINKER" bullets reversed (= loaded into shells base forwards),

with 0.4 gram charges of N 320, before the normal cleaning.

The cast bullet LEE 311-93-1R (author's "pet") of wheel weight lead, resized to

dia. 7.92 mm, avg. weight 5.85 grams, cartridge o.a.l. 59.0 mm, gave velocities:

Charge 0.2 gram Charge 0.3 gram Charge 0.5

gram

265.4

338.3

475.0 avg

262.2

332.2

473.4 lo

269.7

376.8

476.9 hi

Notes: Charge 0.2 gram must be considered as minimum,

or "STARTING LOAD" despite of very small velocity variation. (Some short-lasting

hangfires were noted ! The charge was not yet learnt to "settle" in the shell --

by lifting a rifle muzzle upwards before each shot. Experience taught this old trick of

schuetzen shooters). Charge 0.5 gram was excessive for plain-based light cast bullet. Bore

leaded after five shots. Strings of ten test-shot did not cause lead-fouling with the

lighter charges, although bullets were not "dip lubed". Just the cannelures were

filled with JAVELINA-lube by use of a "LUBRI-SIZER".

Notes: Charge 0.2 gram must be considered as minimum,

or "STARTING LOAD" despite of very small velocity variation. (Some short-lasting

hangfires were noted ! The charge was not yet learnt to "settle" in the shell --

by lifting a rifle muzzle upwards before each shot. Experience taught this old trick of

schuetzen shooters). Charge 0.5 gram was excessive for plain-based light cast bullet. Bore

leaded after five shots. Strings of ten test-shot did not cause lead-fouling with the

lighter charges, although bullets were not "dip lubed". Just the cannelures were

filled with JAVELINA-lube by use of a "LUBRI-SIZER".

SPEER "PLINKER" ½-jacketed bullet, with a dia. 7.82 mm, and avg. wt. 6.48

grams, loaded to the o.a. cartridge length 61.0 mm, gave velocities:

Charge 0.35 gram §Charge 1.00 gram §Charge 1.20 grams

296.0

666.8

753.5 avg

286.4

659.9

749.8 lo

306.9

672.2

756.7 hi

Notes: Accuracy of subsonic 0.35 gram load was very satisfactory to ca. 100 meters ! (Four

shots from five hit in the 30 mm group. One called flyer widened the group up to 47 mm).

First test-shots were loaded with a "Kamikaze-handloader's charge" 0.20 grams,

getting some bullets lodged in the bore. Some others left a lead core and the jacket

separated. There are "some slight differences" between jacketed and cast

bullets..! (See the test results with a LEE 311-93-1R). 0.35 gram is not a strict minimum

load, but the charges less than 0.30 gram are not recommended; even when the powder N 310

is used (unless otherwise noted after additional test-shootings with N 310).

The pocket handgun bullets, salvaged from LAPUA's 7.65 mm Browning cartridges, were with

dia. 7.83 mm, avg. weight was 4.76 grams and they were loaded into cartridges to the

overall length 58.0 mm. Velocities were:

Chrg. 0.50 gram Chrg. 1.00 gram Chrg. 1.20 grams

avg 453.0

770.3

866.7

lo 404.9

764.1

861.9

hi 483.2

779.8

870.2

Notes: The subsonic velocity was found impossible to get, despite of the low friction of

LAPUA's .32 ACP bullets. Velocities were erratic even with the lightest listed 0.50 gram

charge. Author made some penetration tests with the heaviest charge. Despite of the intact

full metal jacket of this bullet, it was a kind of "DumDum" projectile when shot

through a 50 mm (2") plank of soft white pine with a velocity 850 + meters per

second.

It is impossible to find exclusive "fingerprints" of rifling marks from the

remnants of this bullet, which is more "explosive" than are some projectiles

actually filled with the detonating substances and equipped with the impact fuzes.

Penetration depth is, of course, reduced and there is also a risk of

"premature"; it is an explosion during a flight: Centrifugal force may

"atomize" the bullet.

(The frail "varmint bullets" are prone to prematures, when shot from the rifles

like .22-250 or .220 Swift with the highest available velocities). A steep rifling twist

(10") of STEYR S.S.G. rifle was presumably an important factor of this amazing

effect. Range of penetration-test was ca. five meters. The listed charge of 1.2 grams is

not yet the maximum load, but the risk of premature explosions is increasing along with

the bullet velocity.

Gallery-loads were loaded with spherical HAENDLER & NATERMANN's pure lead bullets (for

.31 caliber cap & ball revolvers), diameter 8.0 mm, weight 3.0 grams. All the other

cartridges were loaded with a loose powder, but in the gallery loads was a wadding of

toilet tissue (paper), weight 0.3 grams, rammed on the powder charge. Inside of the case

neck was lubricated with vaseline before the bullet seating with a mere thumb pressure.

Cartridge o.a. length was 55.5 millimeters. Velocities were:

Charge 0.20 gram Charge 0.30 gram

274.8

329.3 avg

237.1

309.9 lo

299.0

346.8 hi

Notes: "Dona nobis E.C. BLANK POWDER !!" This is a fervent prayer to the powder

manufacturers, but a vain hope -- of course..? ("Dona nobis" means:

"Please, give to us..." in the Latin). The powder N 320 is a quickly and cleanly

burning propellant, but still too slow and too hard-to-ignite for the gallery loads of

these .308 Winchester cartridges. Velocity variation was excessive, despite of the wadding

and more than a groove-filling diameter of the bullet. Wadding was needed to prevent of

powder and primer contamination by the soft bullet lubricant. Several years later the

author found the hints:

"HOW TO LOAD THE GALLERY CARTRIDGES CORRECTLY":

Reprime the shells, previously shot in your rifle, without any resizing of them.

Charge them with moderate powder doses.

Use the spherical hard lead or Type Metal bullet which is snugly or tightly fitting into

the case neck.

Push - or hammer (if necessary) - the bullet into the cartridge's neck completely, or

still slightly more deeper.

Fill the cartridge's mouth with a bullet lube or an axle grease AHEAD of the bullet.

The hard lead was an alloy of lead and tin, with

usual proportions 16 to 1. (An alloy 50 to 1 was a common metal for the gallery bullets.

Tin was an expensive substance). The Type Metal was an alloy of the lead (82 %), antimony

(15 %) and the tin (3 %). It was bought usually from the printing shop, as ingots or

worn-out movable types. The Linotype alloy, mentioned in some handloading manuals and cast

bullet handbooks, is almost similar mixture of the heavy metals.

The hard lead was an alloy of lead and tin, with

usual proportions 16 to 1. (An alloy 50 to 1 was a common metal for the gallery bullets.

Tin was an expensive substance). The Type Metal was an alloy of the lead (82 %), antimony

(15 %) and the tin (3 %). It was bought usually from the printing shop, as ingots or

worn-out movable types. The Linotype alloy, mentioned in some handloading manuals and cast

bullet handbooks, is almost similar mixture of the heavy metals.

If the Type Metal spherical cast bullet is too big, add the lead into your alloy. Bullets

shall become smaller in the diameter because of enhanced shrinkage of the metal. Softer

bullets are also more easy to push into the case necks. If the diameter is O.K. but you

needs hard bullets, drop them into the cold water or brine, from the mold, soon after the

solidification of them.

The usual "waiting period" of the cast

ternary alloy bullets is three weeks or 20 days. The final as-cast diameter and hardness

of Pb-Sb-Sn alloy slugs is achieved after three weeks, if the bullets are air-cooled

slowly, but this waiting period is unnecessary if the slugs or balls are quenched suddenly

in the water or in the ice-cold brine. (A solution of common salt and water, made for

brining of the meat or fish. The brine is concentrated enough, when an uncooked potato

floats on it). This is an old trick known by the bullet casters a century ago, but no more

found from the cast bullet handbooks, written by some Engineers Graduate. Hardening of the

steel is based on that same process.

The usual "waiting period" of the cast

ternary alloy bullets is three weeks or 20 days. The final as-cast diameter and hardness

of Pb-Sb-Sn alloy slugs is achieved after three weeks, if the bullets are air-cooled

slowly, but this waiting period is unnecessary if the slugs or balls are quenched suddenly

in the water or in the ice-cold brine. (A solution of common salt and water, made for

brining of the meat or fish. The brine is concentrated enough, when an uncooked potato

floats on it). This is an old trick known by the bullet casters a century ago, but no more

found from the cast bullet handbooks, written by some Engineers Graduate. Hardening of the

steel is based on that same process.

Most riflemen are unwilling to cast and resize their bullets. It is not a pleasant bustle

to dip the molten hot metal or try to prevent leaking of the melter pot's valve. (The

author welded the spout of his production pot blocked for all time, and threw away those

unnecessary moving parts of the valve mechanism, using now-a-days a cast iron dipper

"Patent July first 1890". According to an old Finnish proverb: "VANHA

KONSTI ON PAREMPI KUIN PUSSILLINEN UUSIA." I.e: "An old trick is better one than

a bag full of the new means").

Especially in Finland -- despite of the known fact that our riflemen have more silencers

or suppressors for centerfire rifles than any other nation of just a five millions peoples

in the World -- are the most usually heard words in the sporting goods stores: "EI OO

!" Id est: "We haven't.." There are unavailable lead-alloy bullets for the

most popular rifle caliber cartridges .222 (preferable weight 3.0 grams) or .308/ 7.62 mm

(preferable weight 8 grams/123 grains. Diameters 7.85 mm and 7.92 mm).

Therefore it was mandatory to develop subsonic rifle loads with the jacketed bullets,

despite of the needlessness and harmfulness of the copper alloy "envelope" of

the rifle projectiles, shot with less than 300 meters per second muzzle velocities. A very

thin jacket, or preferably just an electroplating (or a more modern electroless plating),

is O.K. Those "good old time's" jacket alloys LUBALOY or the British NOBELOY

might be also fit for bullets for the subsonic rifle cartridges.

Metallurgists of the plants, rolling the sheets of bullet jacket alloys: WAKE UP !! These

alloys were composition of the copper (95 per cent), zinc (3 %) and tin (2 %). The tin was

needed during the Second World War for some more important purposes, like soft

solderings... But WW II ended in 1945 ..!! Still, almost 55 years later, the riflemen must

use bullets jacketed with a substitute alloy, the Gilding Metal (95 % Cu + 5 % Zn,

nominally) in the Civilized World and brass jacketed bullets in Finland.

Our jacket material is MS 90 alloy ("MS" comes from the word

"messinki" = the brass and "90" from the percentage of copper) because

the Army has demanded use of this particular alloy..! Demanded in 1923, when the State's

Cartridge Factory was founded... Finnish SAKO Oy tried with a success the use of 99.5 %

pure copper as a jacket metal, because the copper is cheaper in Finland than is the 90 %

Cu + 10 % Zn alloy, but in the mid-1980's made SAKO the assault rifle bullets also for the

Finnish Army. And the Armed Forces (read: the hidebound staff officers) dictated terms of

the bullet-making, including a jacket material of those projectiles sold to the hunters

and target shooters.

Today loads SAKO Oy no more cartridges for Finnish Armed Forces, but the pure copper is

not yet an allowed jacket metal. WHY ? Don't ask, please !! SAKO Oy has never reacted to

the friendly letters of the author. (The rival Finnish gunwriters have, of course, seen

them ! They've had a good scoffing laugh, when studying some "too early" product

ideas of the author, along with his "primitive" drawings . But when some

Austrian or American manufacturer have - some years later - put the same "ridiculous

illusions" into the production, successfully, those lousy SAKOcrats are crying; or at

least no more laughing !!)

Returning back to the theme "jacket materials of subsonic rifle cartridge

bullets" and the history of those Good Old Times, the author must point out the good

features of plated steel or iron jacketed projectiles. The mild steel (called as an

"iron" by the old blacksmiths, because it is impossible to harden by heating and

quenching) is a very good jacket material.

Hardness of mild steel is easier to keep uniform than is hardness of the brass. Surface

friction may also be uniform, because the iron jackets are usually plated with some pure

metals; copper, zinc or cadmium, or with alloys like LUBALOY but most usually with the

cupro-nickel. (So called "nickel jacketed bullets" clings usually on the magnet,

being actually C-N plated iron jacketed projectiles. Cupro-nickel, or "melkhyor"

in Russian, is an alloy of copper with a small percentage of nickel for enhanced hardness

and "silvery" color. C-N does not cling on the magnet).

Austrians preferred in the turn of 20th century the unplated mild steel or actually an

almost pure iron as a jacket material. Bullets were coated with a wax or grease. Coating

was a rust preventive, but it also lessened the bore friction. The author tried as early

as in 1981 shooting the LAPUA FMJ bullets S-374 with their cannelures or crimping grooves

filled with TAMARAC bullet lube. After the usual un-cronographed three "bore fouling

shots" gave the first six test-shots the very same velocity within 0.1 meter per

second. Those next four shots developed somewhat higher bullet velocities, when the barrel

of a rifle TIKKA M 55 Sporter warmed up and became more "slippery".

The charge was about a "Maximum Load" and it may be slightly too heavy for some

other rifles and/or combination of cartridge components. Cases were made by LAPUA, of

caliber .308 Winchester but headstamped by European ways "7.62 x 51 ", partially

neck-resized with the LEE LOADER. Primers were VIHTAVUORI No. 28's. Powder was VIHTAVUORI

N 320 "general purpose porous semi-smokeless tubular powder", author's pet in

those years, because it is "a first cousin" if not a twin- sister of German

Platzpatronen Pulver Sorte 33" (according to researchers of German DEVA Research

Institute, including famous Dr. K.D. MEYER). The bullet S 374 weighs 8.0 grams/ 123

grains. Nominal (and usually actual) dia. is 7.85 mm. Two cannelures are turned around a

shank of the bullet. Jacket material is the brass MS 90, but it may become swop to Cu 99.5

%, when some stubborn old-timers of LAPUA-PATRIA are superannuated...

The minimum (STRICTLY a minimum) load gave very erratic muzzle velocities, but it is

almost "silent without a silencer" and therefore practical for the home defense

or other short-range commissions. The maximum (STRICTLY a maximum) load was designed to

duplicate the ballistics of 7.62 x 39 mm YELISAROVa i SYEMINa cartridge of KALASHNIKOVa AK

47 and AKM assault rifles. The load 1.10 grams was, however, somewhat more powerful. One

gram of N 320 or 1.9 cubic centimeters of N 310 is presumably a suitable charge for AK

duplicate loads.

Some records of these test-shootings are lost forever, because they were sent to the

Editorial Office of "ERÄ" magazine along with a manuscript of an article

"Moderate Handloads for .308, Part 2." Chief Editor of "ERÄ" magazine

was fired a week after the delivery of that manuscript, because he refrained from

publishing of "anti-silencer" articles (written in compliance with wishes of

some paranoic PIGs and - of course - the REDs).

"ERÄ" (="The Outdoor Hobbies") magazine has never returned any

material, published or unpublished, to the copyright owners. The first part of an article

re .308 Win. special loads became published in the late 1982, but the material of Part 2.

is lost irrevocably. Just the test-shooting notes of minimum and maximum loads were

preserved for the author, who is a counselor of whole Finnish people in the case of

special handloads.

Those extremity loads for .308 Winchester with dip-lubricated LAPUA S 374 bullet gave

velocities as follows:

Charge 0.40 gram Charge 1.10 grams

190.9

641.0 average

151.2

636.2 lowest

211.0

644.3 highest

MINIMUM LOAD! MAXIMUM LOAD !

Notes: According to the faded remembrance of the author, the charge 0.50 gram of the loose

powder N 320 gave supersonic velocities with each shot from this particular rifle TIKKA M

55 Sporter, made by TIKKAKOSKI Oy by "LEGE ARTIS": Bore was cut-rifled and

hand-lapped. 0.45 gram of N 320 was O.K. in a warm day of early summer.

Dip-lubing of bullets was done by seating them into the cartridges so that a half of the

rearmost (broad) crimp groove was visible from the case mouth. The cartridges were then

dipped into the molten lubricant down to the case mouths, waited ca. 20 seconds, lifted

the bundle of cartridges away from the lube pan, and when the TAMARAC was became solid,

the excess of it was wiped away from the bullets and case necks.

NOTA BENE: This method is useful for lubrication of the cast bullets, which are usually

messy and unpleasant to handle. Cartridge overall length may also become variable, when

the lubricant accumulates into the seater die. It is much more comfortable to seat

unlubricated cast bullets and dip-lube them in the cartridges in the bundle of as many as

a hundred rounds at a time. Many factory-made lead bullets (loose ones or those in the

cartridges) are too thinly lubricated, needing also a dip-lubing. "LEE LIQUID

ALOX" may be useful for dip-lubricating, but a "hot lubing" with a molten

solid stick-wax is a TRIED method. So is also a "dry-wax lubrication" with a

paraffin wax dissolved with the carbon tetrachloride. Unplated .22 rimfire bullets are

most often dry-waxed.

Author tried also an "internal steam lubrication" by the candle stearin, mixed

with a 0.40 gram charge of N 320. Cartridges were bulleted with 7.65 mm Luger/Parabellum

bullets of the unknown origin (presumably SAKO); brass jacketed; wt. 6.0 grams; dia. 7.85

mm. Test-shots were shot again from TIKKA M 55 Sporter. Velocities were fickle, from

subsonic to transsonic:

300.6 m/s average

281.2 lowest

317.0 highest

Notes: The poverty is not a shame, but the independent researcher's life it makes

extremely inconvenient. There were those six grams FMJ bullets just for three

unchronographed fouling shots and seven test-shots. Further tests with the dip-lubricated

bullets are never done - or the tests with "steam-lubed" cartridges with a

powder N 310. Overall cartridge length with those Luger bullets was 62.5 millimeters. The

other components were similar tho those used previously for tests of the .308 Win.

cartridges. The stearin was chipped with a knife. Dose of it was small. Unweighed, but ca.

one tenth of the powder charge "volume by volume".

Six grams bullet weight seems to be suitable for the subsonic target practice and

small-game hunting loads of .30 caliber and 7.62 mm cartridges. There are - of course -

some needs for highly specialized projectiles of the subsonic cartridges, like a more

blunt point-shape, pure copper jacket and the very most novel innovation - a Molybdenum

Bisulphide coating on these bullets. In Finland were those bullets with a weight 6.0 grams

in use since 1936 in 7.62 mm MOSIN & NAGANT "low-pressure cartridges",

loaded with the powder N 14 or predecessor of a modern N 310. Story of these loads will be

told in the third part of "Arcane".

End of second part, continued in part 3.

Part 1 Part

3 Gunwriters' Front Page Suomenkielinen Gunwriters Link

page